The presented configuration is the most frequently chosen by our customers – a proven and efficient solution for serial production.

Main Features:

-

Front supports: 2 pcs on linear guides, ensuring stability during bending operations.

-

Backgauge adjustment (X-axis): automatic

-

Beam adjustment (Y1, Y2 axes): automatic

-

Height adjustment of fingers (R-axis): manual (option*)

-

Double-sided punch clamping: quick-release AMADA type, allowing fast tool changes.

Available configurations are tailored to production needs and the type of processed components – machine specifications are determined individually based on application and technological requirements.

Technical parameters

| Max. bending sheet thickness (S235) |

up to 8.0 mm |

| Nominal pressure |

2000 kN |

| Maximum bending length |

3200 mm |

| Throat depth |

320 mm |

| Maximum ram stroke |

200 mm |

| Maximum open height |

480 mm |

| Distance between frames |

2700 mm |

| Backgauge travel |

500 mm |

| Motor power |

15.0 kW |

| Length |

3300 mm |

| Width |

1800 mm |

| Height |

2700 mm |

| Weight |

11,400 kg |

Manual or automatic height adjustment of backgauges. The R-axis facilitates bending larger radii, e.g. step bending system.

For satisfactory step bending results, it is necessary to make several calculations based on key parameters of the bending process:

- Arc length – the distance between the ends of the curved sheet, measured on the inner side of the bend;

- Number of bends – the number of individual bends needed to achieve the desired radius; the more bends, the smaller the angle of each and the smoother the arc;

- Distance between bends – spacing between consecutive bends during the process.

Although step bending may seem complex, CORMAK machines and software are advanced enough to automate many calculations and assist the operator efficiently.

Automatic crowning compensation

Ensures a consistent bending angle along the entire working length – (option*)

Manual crowning compensation (option*)

Ensures a consistent bending angle along the entire working length – (option*)

High-quality components:

- Electrical components by Schneider / Delta / Eaton

Control and functionality:

CR-41 CNC

- Equipped with a 10-inch touchscreen mounted on a movable arm, providing freedom of operation across the machine’s working area.

- Programmability: up to 2,000 programs with 30 steps each, allowing flexible adaptation to various tasks.

- Ergonomic control: intuitive interface with English abbreviations ensures quick and easy operation.

The machine combines advanced technology with ease of use, making it ideal for both precise manual operations and efficient serial production. High-quality components and advanced safety systems ensure reliability and operator protection.

Safety

Laser safety system

Included as standard – a top-class laser safety system that protects the operator and more than doubles the bending process speed.

No compromises on safety! The machine features top-quality hydraulic connections and safety valves designed for maximum reliability.

Beware of pseudo-safety systems such as gates or light curtains, as they do not comply with CE standards and may endanger workers’ health. As an employer, you are responsible for your employees’ safety!

Safety guards compliant with CE

Ergonomics and additional features:

- Mobile controller on a movable arm

- LED lighting: enhances work comfort and safety

- Front supports on linear guides

Our press brakes are equipped with advanced protection systems including clear safety markings, side guards, rear safety gates, and easily accessible emergency stops.

Each machine comes with a clear and detailed user manual.

Having a CE declaration does not automatically make a machine safe – the safety depends on the systems installed!

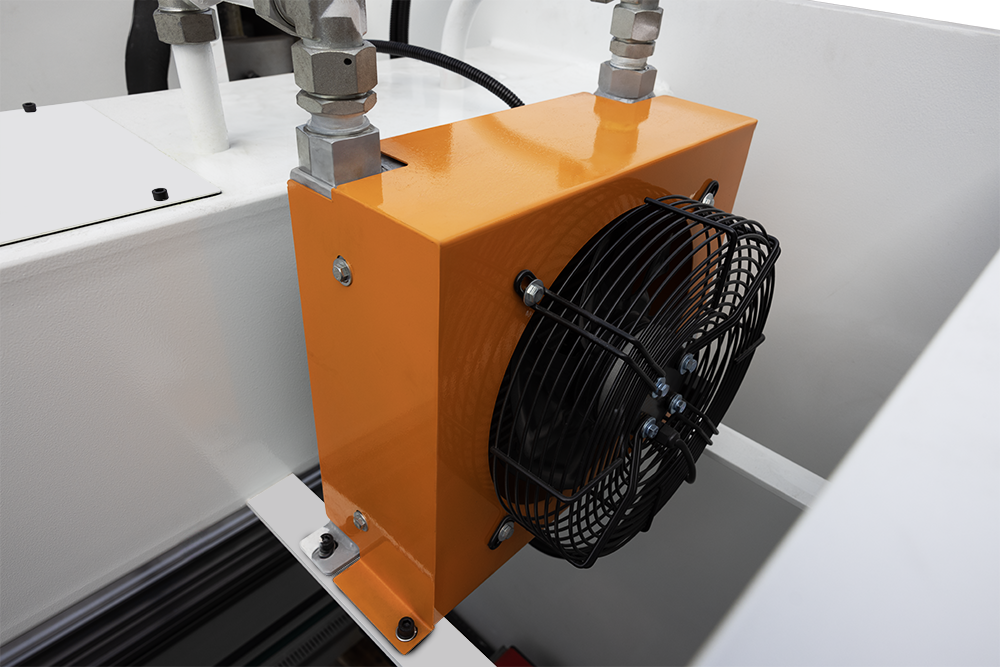

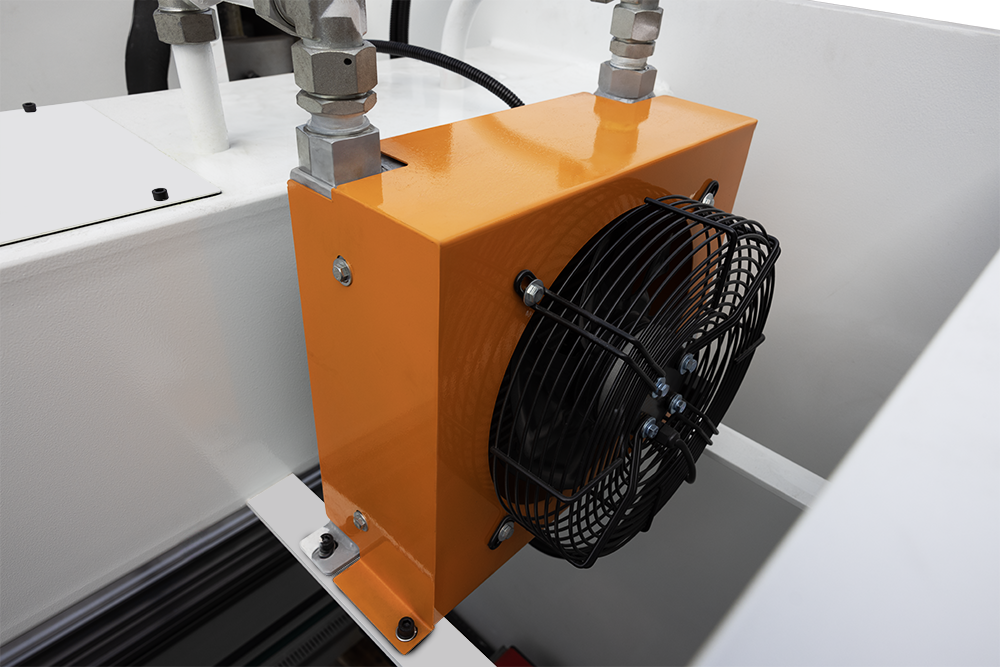

SCO – Oil Cooling System

Standard system ensuring stable operating parameters even during prolonged, continuous operation.

Tool clamping system:

- Standard segmented, four-sided multi-groove dies and sectional punches

- The basic system used in CORMAK press brakes is the manual AMADA (European) type quick-change clamping system.

- Punches are side-mounted and locked with screws.

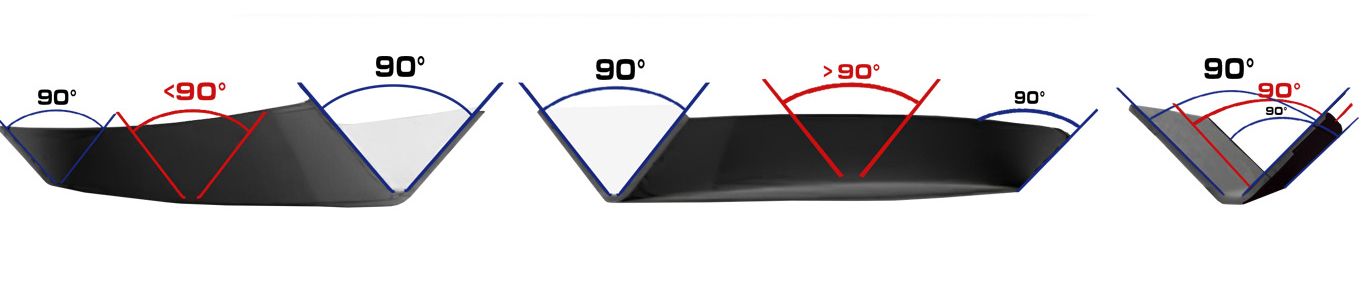

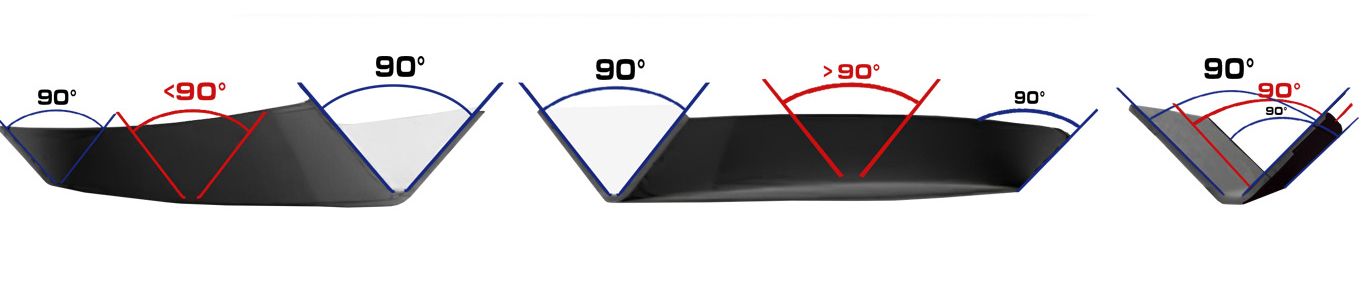

Choice of die and punch

The final result depends on proper selection of die and punch.

CORMAK press brakes continuously measure the bending angle and can automatically correct deviations during the process for optimal results.

Depending on the press force, sectional punches and dies may differ in length.

Included with the machine

Telephone consultations with a specialist

You can always count on professional support from our specialist.

Terms of cooperation

- 24-month warranty period.

- The machine is brand new.

- Warranty and post-warranty service provided by the supplier.

Training and Machine Commissioning

It is possible to arrange professional training and machine commissioning carried out by a Cormak technician — this service is priced individually.

Contact our advisor to get more information.

Contact us

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training — please contact our consultant for more details.

2024-09-08

Funkcjonalna i dokładna

Używamy tej prasy w naszej firmie i jestem bardzo zadowolony. Jest precyzyjna i sprawdza się w codziennych zadaniach.