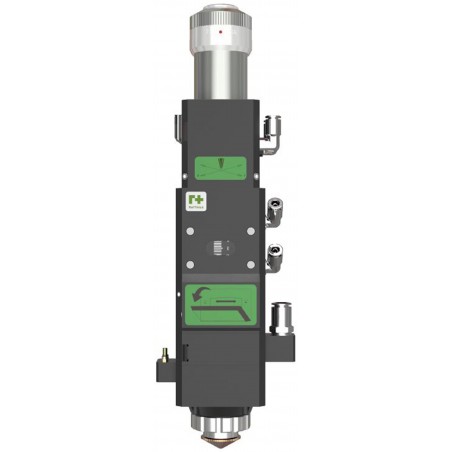

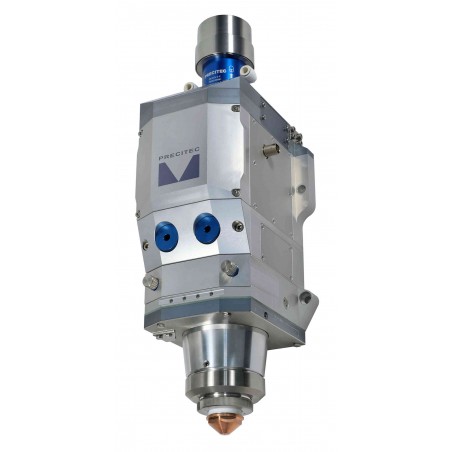

The cutting head is the heart of the fiber laser cutting process: it maintains the correct distance from the material through a capacitive sensor, automatically sets the focal point (autofocus) and shapes the assist gas flow at the nozzle area. As a result, piercing is predictable, the kerf remains stable, and the geometry of the workpiece is consistent throughout the batch. A well-designed nozzle chamber and protective lenses shield the optics from dust and spatter, reducing contamination, deposits and overheating risks. In practice, this leads to cleaner edges, fewer parameter adjustments and lower operating costs.

When selecting a cutting head, consider the FIBER source power, the range of processed materials (carbon steel with oxygen, stainless steel and aluminium with nitrogen or air), the nozzle type and diameter, as well as the required cutting height and speed. Key supporting features include fast autofocus with preset saving, stable optical zone cooling, easy access to the protective glass and quick nozzle replacement. Equally important are machine working conditions: efficient fume extraction, clean and dry process gases and air, proper ventilation and regular inspection of seals and mounting sockets. A well-maintained system ensures stable optical transmission, consistent beam power and extended service life of key components.

For daily operation, quick and clean preparation is essential: replace worn protective glass, select the correct nozzle for material and thickness, perform a piercing test on a reference sample, and save the recipe parameters. This process discipline allows full use of the potential of FIBER cutting heads — from high speed and precision, through clean, burn-free edges, to predictable part cost and reduced service downtime.