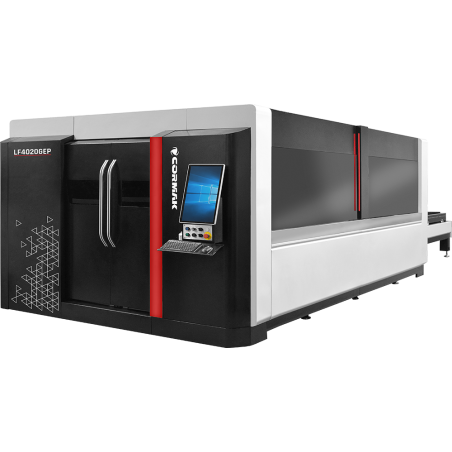

The enclosed construction streamlines the entire process—from sheet loading to finished part removal—while limiting the emission of fumes and scattered radiation outside the working area. The controlled internal environment, with stable ventilation, efficient filtration and cooling, ensures the FIBER source and cutting head maintain consistent parameters, resulting in a clean edge, predictable piercing and uniform kerf width across the entire cut. The enclosed housing, safety curtains/systems and logical service access enhance operator comfort, simplify daily operations and shorten job setup times.

In practice, enclosed laser systems are ideal wherever repeatable quality and compliance with HSE standards are required: multi-shift production, cutting thin to medium sheet thicknesses, or series of components demanding aesthetic edge finish without extensive post-processing. Proper selection of the cutting head (autofocus, fast height sensor), compatible nozzles and protective lenses, as well as an appropriately rated chiller, ensures stable beam power and long optical component life. Good practice includes regular inspection of protective lenses and nozzles, clean process media, stored cutting parameters for reference materials, and maintaining efficient filtration and extraction systems — simple measures that genuinely reduce operating costs and minimise downtime.