Basket

The basket is empty.

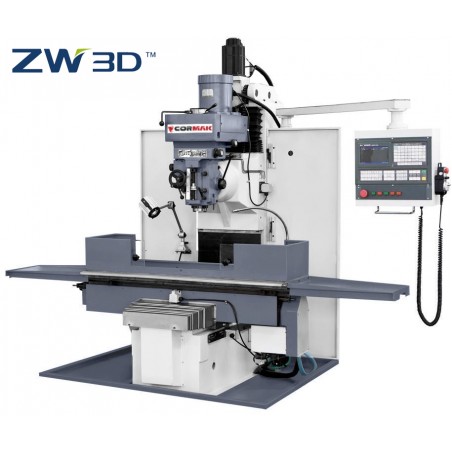

CNC Milling Machine CORMAK MILL 350

The CORMAK MILL 350 CNC Milling Machine operates in three axes, offering linear and circular interpolation, fixed machining cycles, tool compensation, subprogram functions and self-diagnosis. With a spindle speed range of 0–6000 rpm , it enables precise machining of flat and curved surfaces as ...More

- Reduced price

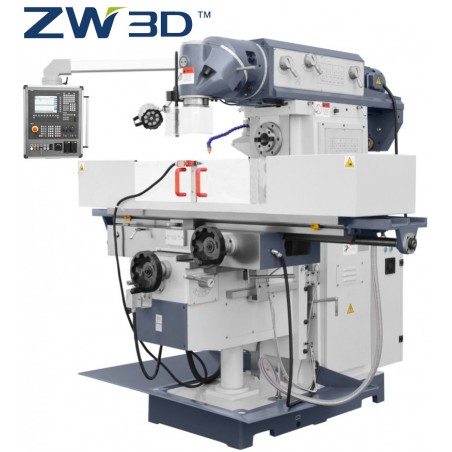

CNC Milling Machine CORMAK MILL 1636

Industrial universal milling machine with CNC control designed for heavy industry and precision tooling. Equipped with a horizontal spindle and swivelling vertical head, the CNC Milling Machine CORMAK MILL 1636 is ideal for toolrooms, workshops, and maintenance departments. The 1600x360 mm ...More

- Reduced price

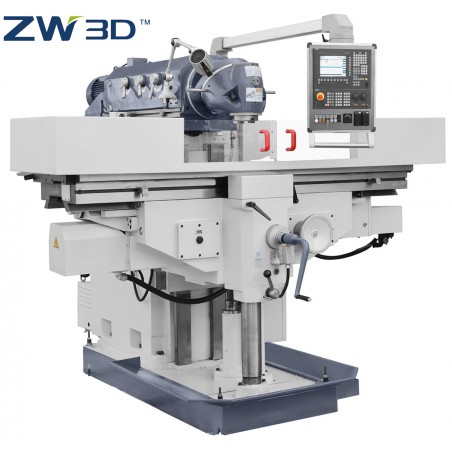

CNC Milling Machine CORMAK MILL 2050

High-quality CNC milling machine with a robust construction. A large worktable allows machining of heavy parts up to 1,800 kg . Servo motors and precision ball screws are used in all axes for smooth and accurate movement, ensuring durability and excellent machining precision. ...More

- Reduced price

CNC Milling Machine CORMAK VM1320

The CORMAK VM1320 CNC Milling Machine is designed for machining individual parts and small series. Its heavy cast-iron base and large worktable provide excellent stability and flexibility, enabling precise metal machining even for small batches. The user-friendly CNC interface allows fast and ...More

CNC Milling Machine CORMAK VM1370

The CORMAK VM1370 CNC Milling Machine is an industrial-grade universal milling machine designed for heavy-duty applications, workshops, toolrooms and maintenance departments. Equipped with a horizontal spindle and a swivelling vertical head, it provides excellent flexibility in machining. The ...More

CNC Milling Machine CORMAK VM1700

The CORMAK VM1700 CNC Milling Machine is designed for machining individual parts and small series. Its heavy cast-iron frame and large worktable provide exceptional stability and flexibility in metal machining. Fast and simple CNC programming allows for rapid changeovers, making this machine ...More

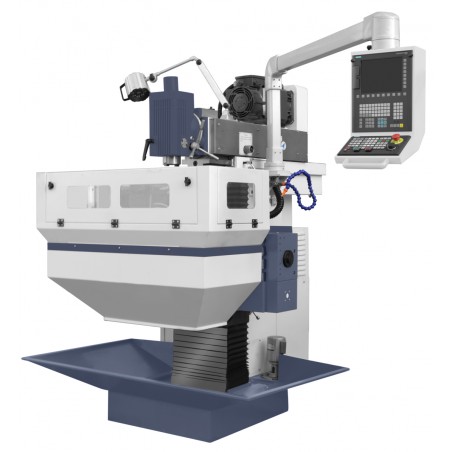

CNC Milling Machine CORMAK MILL 1500++ with Swivelling Head

CNC Milling Machine CORMAK MILL 1500++ is an advanced CNC machine designed for precise metalworking in demanding industrial environments. With its robust construction, modern CNC control, and large working area, this metal machining centre ensures reliability, high efficiency, and versatility. ...More

CNC Toolroom Milling Machine CORMAK XN830

The CORMAK XN830 CNC Toolroom Milling Machine is equipped with a vertical milling head tiltable by ±60° and a horizontal milling setup. Designed primarily for toolrooms and workshops producing complex, high-quality components, its construction allows machining of relatively large workpieces ...More

CNC Toolroom Milling Machine CORMAK XN840

The CORMAK XN840 CNC Toolroom Milling Machine features a vertical milling head swivelling within ±60° and a horizontal milling setup. It is designed primarily for toolrooms and workshops producing complex, high-quality parts. Despite its compact size, the robust structure allows machining of ...More

CNC Toolroom Milling Machine CORMAK XL8140

The CORMAK XL8140 CNC Toolroom Milling Machine is designed for toolrooms and workshops producing complex, high-quality components. Despite its compact size, the solid structure enables machining of relatively large workpieces with high precision and stability. Equipped with Siemens Sinumerik 808D ...More

CNC milling machine – what it is and how it works

A CNC milling machine is a computer-controlled machine tool designed for precise machining of steel. Its operation is based on numerical technology that enables accurate control of cutting tool movement. The process is managed by entering dedicated programs into the machine’s system. Each program defines work parameters such as speed, cutting depth, and tool path trajectory.

CNC technology has revolutionised traditional machining processes. The tools move along several axes simultaneously, allowing the creation of complex shapes with exceptional accuracy. CNC milling machines are equipped with automatic tool changers, significantly reducing operation time. Their versatility makes them suitable for a wide range of industries — from automotive and aerospace to medical manufacturing.

The main components of a CNC milling machine include a spindle that drives the cutting tool, and a worktable on which the workpiece is placed. Tool and table movements are coordinated by control software, eliminating the risk of human error. With precise control, the machine enables the repeatable production of identical parts with consistent quality.

CNC milling machines for metal – key advantages

CNC milling machines for metal stand out with numerous advantages. Above all, they provide unmatched machining precision. Numerical control allows for perfectly smooth surfaces and faithful reproduction of even the most complex designs. This makes industrial milling machines indispensable for production processes requiring high accuracy.

Another advantage is their versatility. A CNC milling machine for metal is suitable for both roughing and finishing operations. As a result, it is used in mould, die, and prototype production. The solid construction of these machines allows the machining of hard materials such as steel, aluminium, or copper without risk of deformation.

Numerically controlled milling machines are also valued for their efficiency. Automation significantly shortens production time, and the ability to save and reuse programs allows quick project adjustments. By utilising advanced technologies, these machines minimise waste, directly reducing production costs.

Within the range of CNC machines offered by the industrial machinery manufacturer CORMAK, you’ll find models designed for a wide variety of applications. Thanks to advanced functions such as linear and circular interpolation, CNC milling machines for steel perform excellently even under demanding conditions.

How to choose the right CNC milling machine

Choosing the right CNC milling machine depends on several key factors. The first is the type of material to be machined. A CNC milling machine for steel requires a rigid structure and a powerful spindle to handle tough materials. Educational milling machines, also available in CORMAK’s offer, are designed for training and smaller workshop applications.

Another consideration is the range of operations the machine will perform. For large manufacturing facilities, the best choice is an industrial-grade milling machine with high power and flexibility. For companies specialising in precision components, models with superior accuracy and minimal tolerances are recommended.

Attention should also be paid to control software. An intuitive interface makes programming easier, while compatibility with popular CAD/CAM formats speeds up design work. Models with additional features such as automatic tool changers or self-diagnostic functions enhance convenience and productivity.

Industrial milling machines in the CORMAK range

CORMAK offers a wide selection of CNC milling machines suitable for various industries. Among them, you’ll find both roughing machines and advanced educational models. All milling machines are characterised by robust construction and modern control systems, ensuring long-term reliability.

The industrial milling machines in our range are known for their exceptional precision and versatility. Models such as the roughing milling machines perform perfectly in heavy industry and toolmaking environments. Each machine has been designed for maximum performance and operator comfort.

We invite you to explore the full CORMAK range. You are sure to find solutions tailored to your needs.