Metalworking machines – what are they?

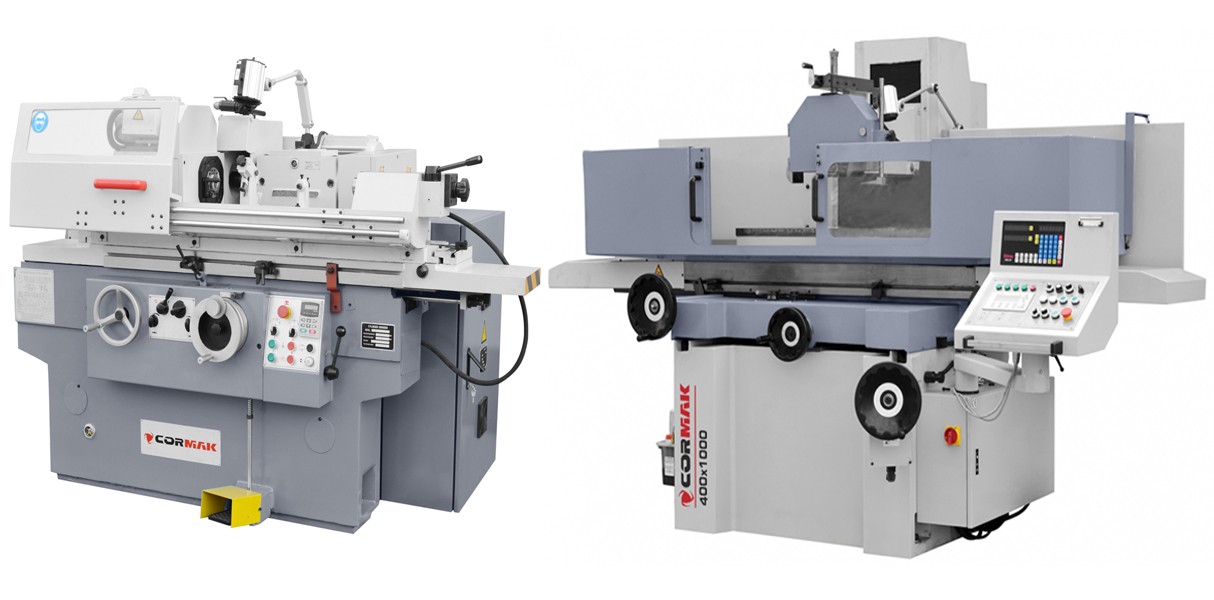

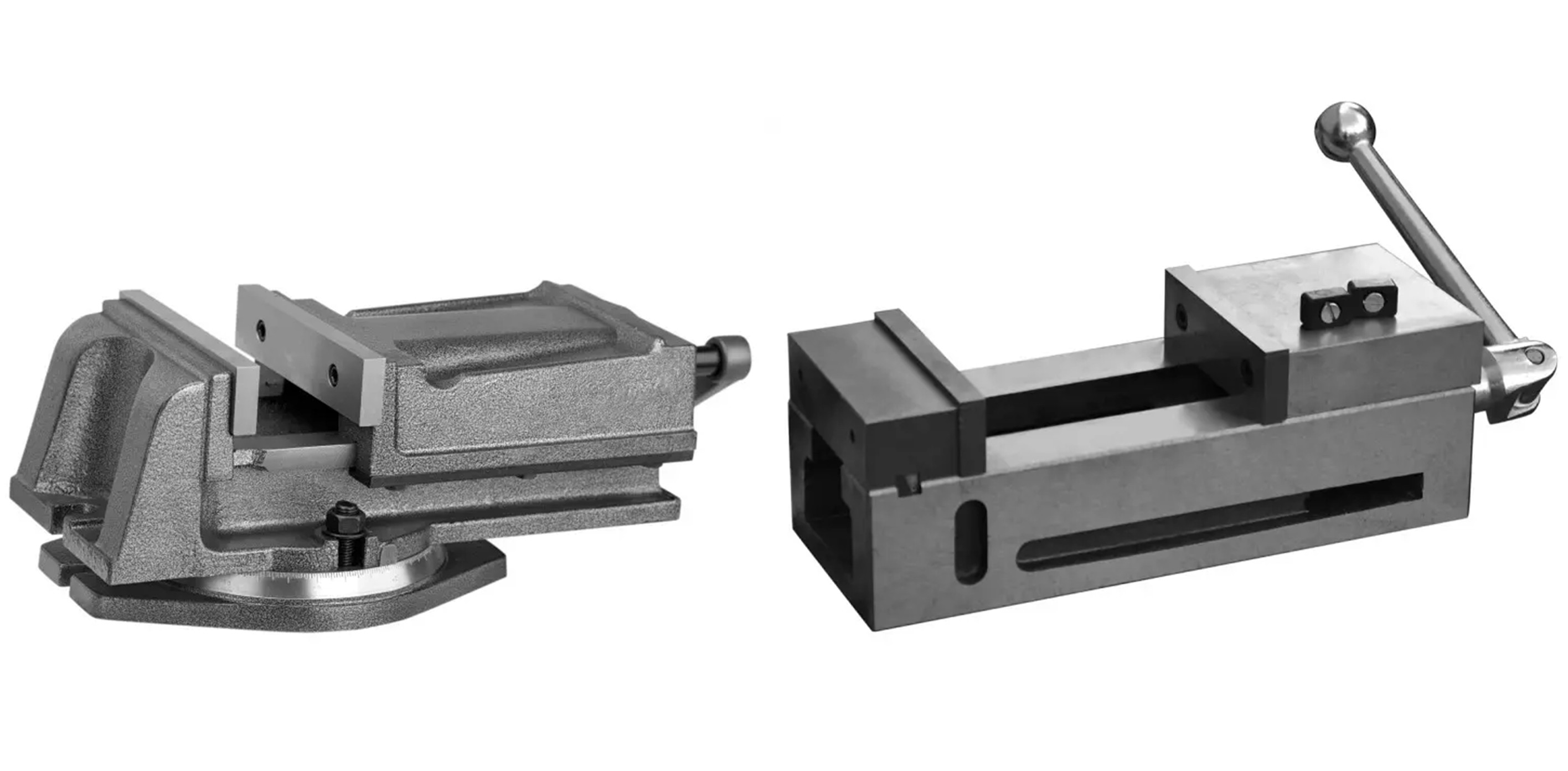

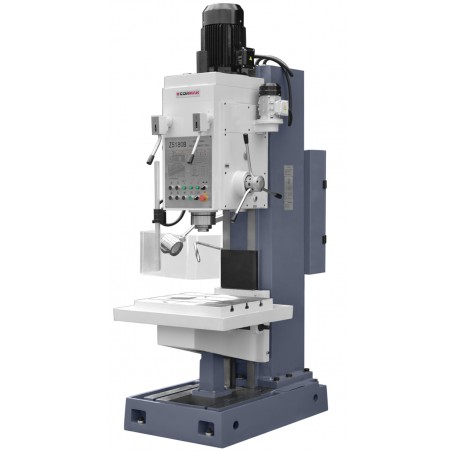

Metalworking machines are a wide range of tools used across many industrial sectors. They are used to produce components for building other machines or devices, as well as to manufacture profiles for commercial, private and safety applications. They are divided into two main groups — CNC numerically controlled machines and conventional machines available in our range, such as milling machines, lathes, bandsaws and others.

Milling machines are efficient tools used in the engineering industry for machining flat surfaces with cylindrical, end or face mills. They also machine non-rotational shaped surfaces using form cutters. Lathes are machines used for machining external and internal rotational surfaces — turning and boring. Bandsaws, on the other hand, cut, separate and shape materials, ensuring continuous cutting performance. After machining with a conventional machine, the finished product is ready for use. The undeniable advantage of these machines is their relatively low production cost, allowing manufacturing companies to offer competitive pricing to their customers.

Why invest in a metalworking machine?

Every metalworking machine plays an essential role in the production process. They allow the transformation of raw metal into complex, precisely shaped components required for a variety of industrial applications. Therefore, in every workshop, depending on its profile, you can find the right machine for the job. Proper knowledge of the machine type and its purpose is key to achieving optimal results.

Investing in metalworking machines can bring many benefits to both industrial companies and craftsmen. The most important of these is undoubtedly efficiency. Metalworking machines allow automation and acceleration of production processes. They enable higher performance in a shorter time, increasing the number of produced parts and components. Another important aspect is that advanced metalworking machines are equipped with precise tools and control systems, enabling extremely accurate machining. This is especially vital for parts with complex geometries or tight tolerances.

By investing in metalworking machines, you can also expand your production capacity. Thanks to the wide range of available machining processes, such machines enable multiple operations such as milling, turning, drilling and cutting, increasing production flexibility and allowing for more complex projects. Automation of metalworking processes also saves time and labour costs. Automated machines operate faster and more efficiently than traditional manual methods, reducing lead times and minimising errors. Through precise metal machining with modern equipment, it is possible to achieve products of excellent quality and finish. This enhances the company’s reputation and customer satisfaction.

It is worth noting that investing in metalworking machines requires an initial financial outlay, but over time it can deliver substantial profits by improving productivity, product quality and overall competitiveness.

As a manufacturer of industrial machinery, we provide our customers with durable and reliable metalworking equipment that will serve for many years. Decades of experience and continuous development have allowed Cormak to create top-quality metalworking machines that are not only dependable but also safe to use and easy to operate. Also explore our industrial machinery and other products such as:

We invite you to explore our full range! We’re confident you’ll find exactly what you’re looking for.