Select your delivery country

-

Menu

-

Products

-

-

-

- FIBER laser cutting machines

- CO2 laser cutting machines

- Laser welding machine

- Fiber Cleaning Laser

- Plasma cutters

- Laser fume extractor

-

-

-

-

-

-

-

-

-

-

-

- CNC Routing Machines

- Sliding Table Panel Saws

- Edge Banders for Straight and Curved Edges

- Table Saws

- Spindle Moulders

- Dust, Chip and Shaving Extractors

- Sanders

- Planer Thicknessers

- Wood bandsaws

- Woodworking Combination Machines

- Sanding Tables for Woodworking

- Log Splitters & Wood Chippers

- Pendulum and swing saws

-

-

-

-

-

-

-

-

-

-

- About us

- Financing

-

TRADE FAIR

-

-

launches

-

-

Start-ups of CNC milling plotters

- C1212 Premium , C1520 Premium C2030 Premium

- CNC CORMAK C2040 PREMIUM Vacuum pump

- CNC machining centre C2030 IND with Italian spindle

- CNC milling machine C2131

- CNC milling plotter C1325

- CNC milling plotter Cormak C1325 Premium

- Delivery of CNC milling plotter C1530

- Delivery of CNC router C6090 Cormak

- Delivery of the C6090 machine

-

-

-

- CNC milling machine C2141 in ATC version

- CNC milling machine C6090 with 600x900 work area.

- CNC milling machine Cormak NST2131129A LOADING/UNLOADING

- CNC milling plotter C1325

- CNC router CORMAK C2030 ATC

- Milling plotter C1212

- Milling plotter C1212 Premium

- Milling plotter C2030 Premium Cormak

- Milling plotter C2131 Premium

-

-

-

- CNC milling plotter C2040 ATC

- CNC milling plotter C2141 ATC

- CNC milling plotter CORMAK C1212 Premium

- CNC milling plotter Cormak C1325

- CNC milling plotter Cormak C1325 Premium

- CNC milling plotter Cormak C1520

- CNC milling plotter CORMAK C2030 in ATC version

- CNC milling plotter engraving machine C1212

- HK52 CNC milling plotter with infeed and outfeed table

-

-

-

- CNC M1325 milling plotter for stone, granite, gravestones

- CNC milling plotter Cormak C1525 Premium

- CNC milling plotter with a working area of 1500x3000.

- CNC router C2030 ATC with automatic tool changer

- Cormak CNC-Fräsbohrplotter C6090

- HK52 CNC milling plotter with infeed and outfeed table

- Introducing the delivery of the CNC C2040

- Premium milling plotter C1212

- We would like to introduce you to the latest industrial CNC milling machine for nesting.

-

-

-

-

-

-

Commissioning of metalworking machinery

-

-

- SERVICE

- Blog

- Bestsellers

- Contact

- Products

-

- Laser and Plasma Technologies

- CNC Machines

- Metalworking Machines

- Sheet Metalworking Machines

- Woodworking Machines

- CNC Routing Machines

- Sliding Table Panel Saws

- Edge Banders for Straight and Curved Edges

- Table Saws

- Spindle Moulders

- Dust, Chip and Shaving Extractors

- Sanders

- Planer Thicknessers

- Wood bandsaws

- Woodworking Combination Machines

- Sanding Tables for Woodworking

- Wood Drilling Machines

- Chip Extractor Fans

- Centrifugal Fan Blowers

- Sharpening Machines

- Log Splitters & Wood Chippers

- Bandsaw Mills

- Wood Gluing Presses

- Pendulum and swing saws

- Screw Compressors, Dryers & High-Pressure Air Tanks

- Handling Equipment

- Sandblasting & Cleaning Systems

- Machine Spare Parts

- Popular products

- Laser and Plasma Technologies

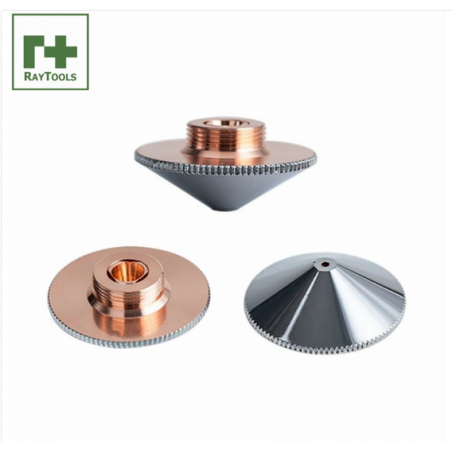

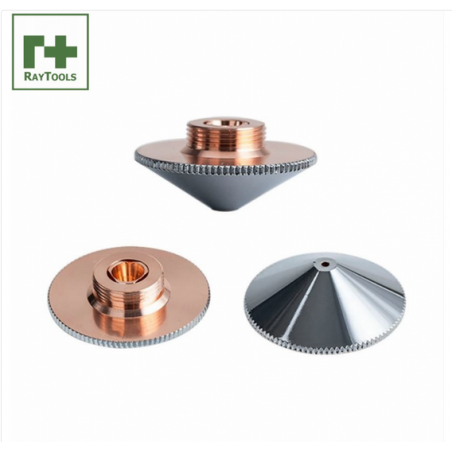

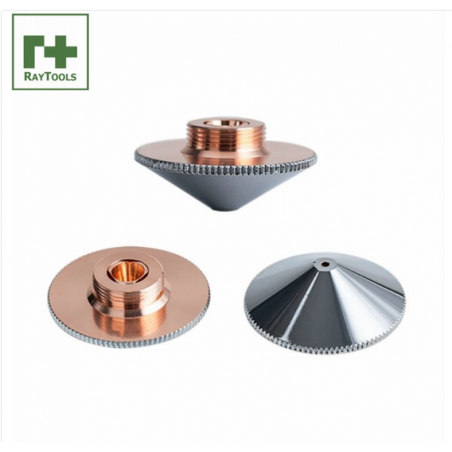

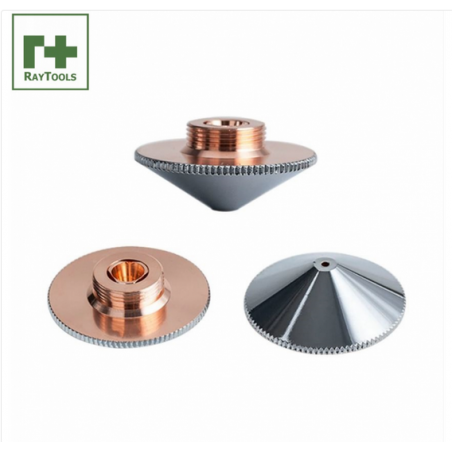

Raytools laser cutting nozzles

Raytools cutting nozzles shape the protective gas stream, stabilise the piercing process, and determine the edge quality and kerf width. Proper selection of nozzle diameter, geometry and type for the material and process parameters improves repeatability, shortens processing time, and protects the optics from contamination.

Raytools Laser Cutting Nozzles

Active filters

The nozzle is the final element in the cutting process: it precisely directs the gas (oxygen, nitrogen, air) that cools the cutting zone, removes molten material, and supports the stability of the optical plasma/beam during piercing. The choice of nozzle affects the edge quality and colour, burr formation, kerf width, and the process’s sensitivity to variations in height and speed. A too small diameter limits flow and increases the risk of burns; a too large one reduces gas concentration and may cause a tapered kerf. The front-face geometry and the nozzle–material distance are also crucial — maintaining the correct separation stabilises the height sensor and ensures consistent cutting along the entire workpiece.

When selecting a nozzle, check compatibility with the Raytools head model as well as the type and thickness of the processed material. Carbon steels cut with oxygen usually require a slightly different diameter than stainless steel or aluminium cut with nitrogen or compressed air; smaller diameters are better for thin sheets to achieve a finer edge, while larger ones ensure adequate flow and debris removal in thicker materials. The quality of nozzle manufacture is equally important: smooth, clean hole edges and even nickel or brass coating contribute to a stable, axial gas stream and reduce clogging risk.

- Products

-

- Laser and Plasma Technologies

- CNC Machines

- Metalworking Machines

- Sheet Metalworking Machines

- Woodworking Machines

- CNC Routing Machines

- Sliding Table Panel Saws

- Edge Banders for Straight and Curved Edges

- Table Saws

- Spindle Moulders

- Dust, Chip and Shaving Extractors

- Sanders

- Planer Thicknessers

- Wood bandsaws

- Woodworking Combination Machines

- Sanding Tables for Woodworking

- Wood Drilling Machines

- Chip Extractor Fans

- Centrifugal Fan Blowers

- Sharpening Machines

- Log Splitters & Wood Chippers

- Bandsaw Mills

- Wood Gluing Presses

- Pendulum and swing saws

- Screw Compressors, Dryers & High-Pressure Air Tanks

- Handling Equipment

- Sandblasting & Cleaning Systems

- Machine Spare Parts

- Popular products

- Laser and Plasma Technologies