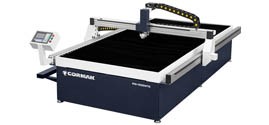

What are CNC plasma cutters?

CNC plasma cutters are industrial machines that use plasma technology for cutting metal. The process involves generating a plasma jet – gas heated to extremely high temperatures – which melts and cuts through the material. With CNC computer control, CNC plasma cutters ensure highly accurate and repeatable cutting, which is essential for series production.

At CORMAK, you will find plasma cutting machines capable of cutting different types of metal, including:

- carbon steel;

- alloy steel;

- stainless steel;

- aluminium;

- brass;

- bronze;

- copper;

- titanium.

These advanced machines are suitable for both cutting and grooving metal components. CORMAK CNC plasma cutters feature modern CNC control systems that simplify operation and enable automation of many production processes.

Applications of CNC plasma cutters

A CNC plasma cutter is widely used across various industrial sectors. Its main purpose is precise cutting of complex shapes from sheet metal. Thanks to programmable and automated control, CNC plasma systems are ideal for serial production, where speed and precision are crucial.

Main applications of CNC plasma cutters include:

- manufacturing structural components;

- cutting sheet metal of various thicknesses;

- producing machine parts;

- automotive parts manufacturing;

- cutting decorative metal elements;

- metal grooving for channels and recesses.

CORMAK CNC plasma cutters are used by both large industrial companies and smaller workshops. Their flexibility and versatility make them indispensable tools for any metalworking operation.

Why invest in CORMAK plasma cutters?

Choosing a CORMAK CNC plasma cutter is an investment that delivers long-term benefits. Above all, these machines offer exceptional precision, ensuring high-quality cutting even for complex projects. CORMAK plasma cutters are characterised by durable construction and modern software that simplifies operation.

The main advantages of CORMAK CNC plasma cutters include:

- High cutting precision – advanced CNC control ensures accurate cutting of even the most complex shapes;

- Speed – plasma technology significantly reduces cutting time, increasing production efficiency;

- Repeatability – programmable operation guarantees identical cuts, ideal for serial manufacturing;

- Versatility – suitable for cutting various materials;

- Low operating cost – robust construction and high-quality components ensure durability and reliability, reducing maintenance costs.

As an experienced manufacturer of industrial machines, CORMAK provides comprehensive technical and service support for every machine purchased. This ensures that your industrial machines will perform reliably for years to come.

We invite you to explore our full range of laser machines, CNC plasma cutters and plasma sources. If you have any questions, our specialists are ready to assist you in choosing the right solution.