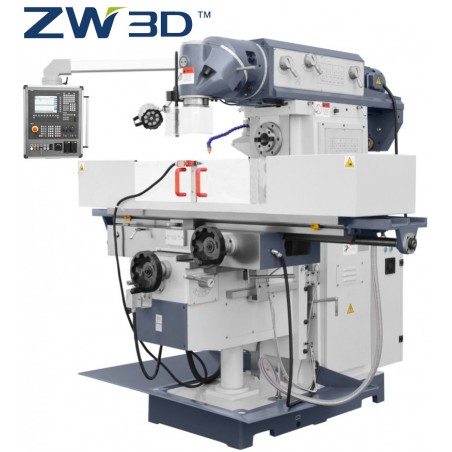

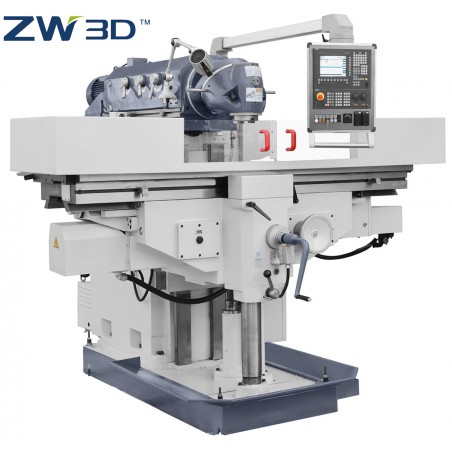

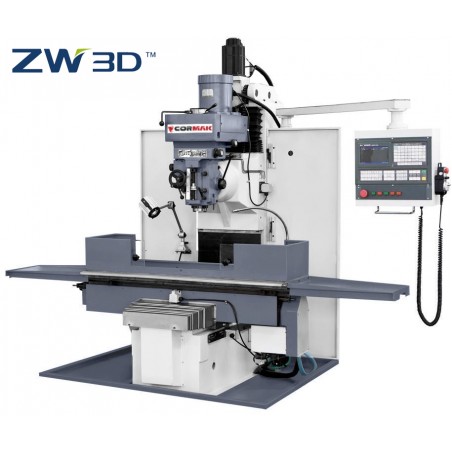

CNC roughing mills are powerful machines designed for fast and efficient removal of large amounts of material from heavy and oversized workpieces. They are ideal for industrial applications where rough milling of metals, structural steel, cast iron or other hard alloys is required. These milling machines feature: a massive and rigid construction (e.g. cast-iron bed, heavy-duty guides), vibration resistance, high-performance axes and servo drives, large X, Y, Z travel and generous table movements, capability to accommodate cutters of large diameter and working length, a powerful spindle, and a large working table to handle heavy and extensive components. The CNC control is optimised for rough cutting, often including options for cooling, lubrication and automatic feed. With CORMAK CNC roughing mills, you can significantly shorten material removal time, reduce intermediate operations, limit tool wear and increase the overall productivity of your workshop. They are an excellent choice if your production involves pre-machining of heavy-duty components, such as in foundries, steelworks, construction or toolmaking facilities, which are later subject to finishing machining.