RÖNTGEN HM-Titan B0 forteC Band Saw Blade – Carbide-Tipped Cutting Blade for Extremely Hard Materials

RÖNTGEN HM-Titan B0 forteC Metal Saw Blade is an industrial-grade cutting blade featuring carbide teeth coated with a layer that enhances heat and wear resistance. It has been specifically designed for cutting extremely hard materials such as heat-resistant alloys, hardened tool steels, titanium, and inconel. Thanks to its construction and advanced coating, this saw delivers maximum durability, cutting stability, and surface quality even at high cutting speeds.

Main Advantages of the RÖNTGEN HM-Titan B0 forteC Band Saw Blade

- Carbide (HM) teeth – provide very high hardness and wear resistance.

- Special protective coating – improves heat resistance and reduces friction when cutting demanding materials.

- Stable operation – exceptional rigidity and vibration elimination when cutting hard materials.

- High surface quality – reduces the need for post-processing.

- Extended tool life – perfect for continuous industrial use.

Construction and Technology

The HM-Titan B0 forteC cutting blade combines the latest advances in materials engineering and cutting technology. The working section is made of carbide inserts – an extremely hard material that retains its cutting performance even at high operating temperatures. The additional protective coating provides anti-adhesive properties and increased resistance to temperatures exceeding 800°C. The hardened alloy-steel backing offers excellent fatigue and tensile strength, allowing continuous operation on dense and hard materials under heavy load conditions.

Precision and Performance

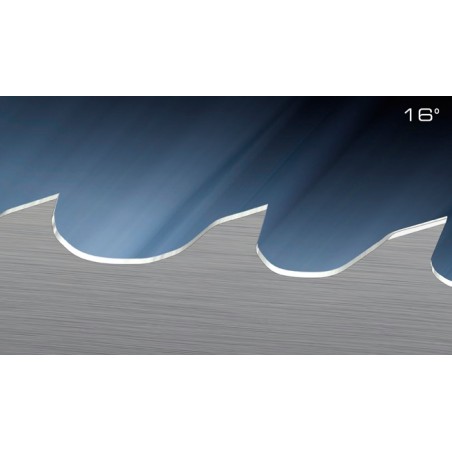

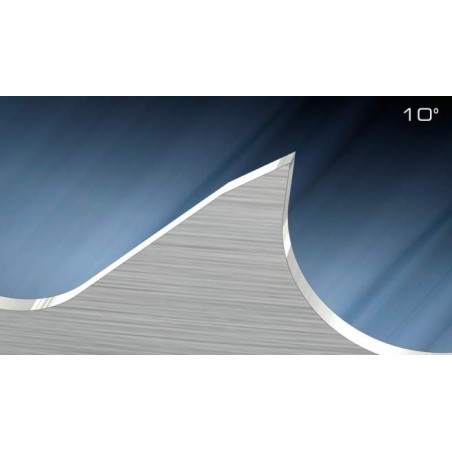

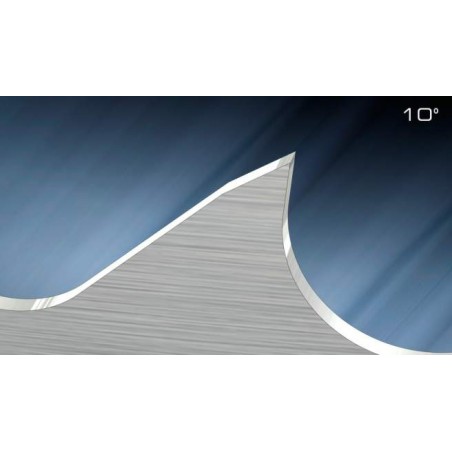

The HM-Titan B0 forteC Band Saw Blade ensures precise, fast, and stable cutting of materials that are challenging for conventional blades. With optimised tooth geometry and advanced coating properties, it reduces friction, energy consumption, and overheating. The blade delivers a superior cutting line and minimises burr formation, making it ideal for serial production processes that require repeatability and reliability.

Applications

RÖNTGEN HM-Titan B0 forteC Cutting Blade is designed for cutting:

- Tool, hardened, and heat-treated steels,

- Titanium, inconel, hastelloy and other heat-resistant alloys,

- Acid-resistant and duplex stainless steels,

- Large-diameter shafts and heavy industrial components,

- Continuous or serial production under high thermal load.

Standard Equipment

- Carbide (HM) teeth with protective coating,

- High-fatigue-strength spring steel alloy backing,

- Tooth geometry optimised for high thermal and mechanical loads,

- Factory welds ensuring readiness for immediate use.

Optional Equipment

- Tooth pitches: 1.4/2 – 4/6 TPI depending on material and section size,

- Band lengths compatible with CORMAK and other industrial machines,

- Special versions for cutting very thin or thick materials.

Technical Data

| Parameter | Value |

|---|

| Band type |

Carbide-tipped (HM) + protective coating |

| Tooth material |

Carbide (HM) |

| Coating |

Anti-adhesive, heat-resistant coating |

| Backing band |

Alloy spring steel |

| Band width |

27 – 67 mm |

| Band thickness |

0.9 – 1.6 mm |

| Tooth pitch |

1.4/2 – 4/6 TPI |

| Applications |

Hard steels, superalloys, high thermal load cutting |

Choose a Tool for Specialised Applications

RÖNTGEN HM-Titan B0 forteC Metal Saw Blade is the perfect choice for industrial users and workshops requiring maximum efficiency, precision, and durability when working with extremely hard materials. This reliable cutting blade is designed for professionals seeking to reduce production time while achieving an excellent surface finish.

Order now and experience the difference a premium-class band saw blade makes in your production process.

Write your review

* Required fields

I accept privacy policy rules