RÖNTGEN Bi-Alfa RP Master Bimetal Band Saw Blade – industrial-grade cutting blade for aggressive and precise cutting

RÖNTGEN Bi-Alfa RP Master Bimetal Band Saw Blade is an advanced cutting blade designed for professional cutting processes that require both high efficiency and excellent surface quality. This model combines the proven design of the Master blade with the aggressive RP rake angle and triple chip tooth geometry, providing efficient and fast cutting of a wide range of materials, including hard-to-machine alloys.

Main advantages of the RÖNTGEN Bi-Alfa RP Master band saw blade

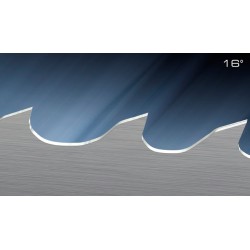

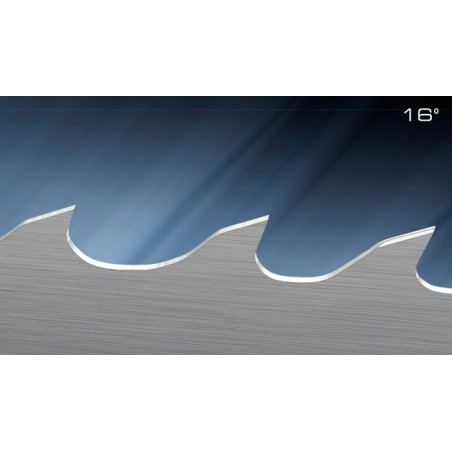

- Triple chip tooth geometry – optimal cutting force distribution for clean and perpendicular cuts.

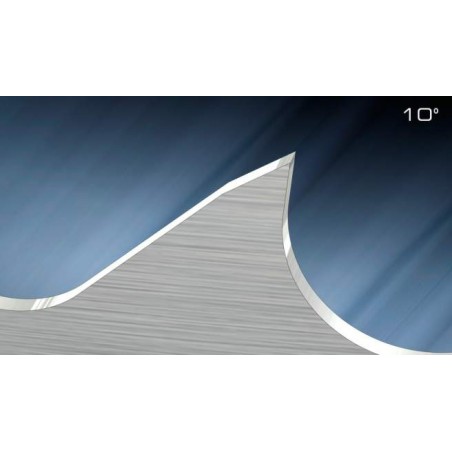

- RP rake angle – aggressive cutting of hard and solid materials without compromising precision.

- CBN finishing – perfect surface quality and extended tool life.

- HSS M42 cutting edge – excellent wear and heat resistance.

- Stable and quiet operation – vibration reduction at high cutting speeds.

Design and technology

The RP Master metal band saw blade is an industrial-grade tool that combines three key technologies: an aggressive RP rake angle, triple chip geometry, and CBN finishing of the teeth. This configuration maximizes the performance of the high-speed steel (HSS M42) used in the blade’s cutting zone. The backing strip is made of fatigue-resistant spring steel, ensuring durability and crack resistance. The RP angle enables fast material penetration, while the triple chip geometry reduces cutting forces and improves the surface finish quality.

Precision and performance

The RÖNTGEN RP Master enables fast cutting of even the hardest materials without compromising perpendicularity or surface smoothness. Thanks to the combination of aggressive geometry and precision-ground teeth, it achieves a highly efficient cutting process while minimizing blade wear. This band saw blade is ideal for use in automatic saws where repeatability, longevity, and superior cut quality are essential.

Applications

The RÖNTGEN Bi-Alfa RP Master Bimetal Band Saw Blade has been designed for the most demanding applications, such as:

- Cutting alloy, tool, and stainless steels,

- Machining solid forgings and large-diameter bars,

- Mass production on automatic and CNC band saws,

- Machine-building and metallurgical industries requiring superior surface finish,

- Toolmaking and metal workshops performing precision cuts of solid structural materials.

Standard equipment

- HSS M42 cutting blade with triple chip tooth geometry and RP rake angle,

- Backing strip with enhanced fatigue resistance,

- CBN-finished teeth for maximum precision,

- Pre-welded ends ready for immediate installation in band saw machines.

Optional equipment

- Tooth pitches: 2/3, 3/4, 4/6 TPI – depending on material type and cross-section,

- Blade lengths adapted to CORMAK and other manufacturer saws,

- Special versions for cutting duplex steel, Inconel, titanium, and high-hardness materials.

Technical data

| Parameter | Value |

|---|

| Blade type |

Bimetal HSS M42 |

| Tooth geometry |

Triple chip with RP rake angle |

| Finishing |

CBN technology |

| Tooth material |

High-speed steel M42 |

| Blade width |

13 – 41 mm |

| Blade thickness |

0.9 – 1.3 mm |

| Tooth pitch |

2/3 – 4/6 TPI |

| Application |

Hard-to-machine materials, stainless steel, heat-resistant alloys |

Choose performance and precision – choose RP Master

If your goal is metal cutting at high speed without compromising edge quality or tool life, the RÖNTGEN Bi-Alfa RP Master cutting blade is the perfect solution for demanding professionals. It combines cutting aggressiveness with full process control – ideal wherever time, precision, and reliability matter most.

Order today and optimize your cutting processes with the industrial-grade RP Master band saw blade.

Write your review

* Required fields

I accept privacy policy rules