RÖNTGEN Bi-Alfa Cobalt M51 Band Saw Blade – cutting blade for high-hardness metals

The RÖNTGEN Bi-Alfa Cobalt M51 Band Saw Blade is a technologically advanced industrial cutting blade engineered for cutting hard-to-machine metals with high strength and heat resistance. With the use of HSS M51 high-speed steel alloyed with cobalt and tungsten, the M51 metal-cutting blade delivers exceptional durability, wear resistance, and stable performance at high operating temperatures.

Main advantages of the RÖNTGEN Bi-Alfa Cobalt M51 bandsaw blade

- High thermal resistance – thanks to HSS M51 steel containing 10% cobalt and tungsten for superior heat stability.

- Extended tool life – improved resistance to wear and micro-cracking during continuous operation.

- Bimetal construction – flexible alloy steel backing with high chromium content ensures excellent fatigue strength.

- Precise cutting of hard materials – ideal for tool steels, stainless steels, and high-alloy materials.

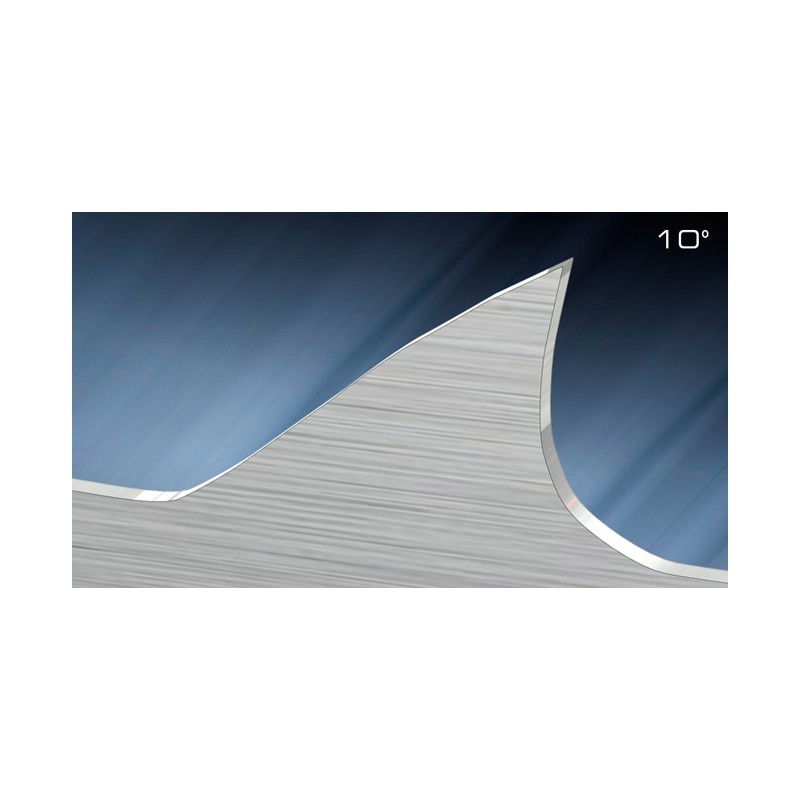

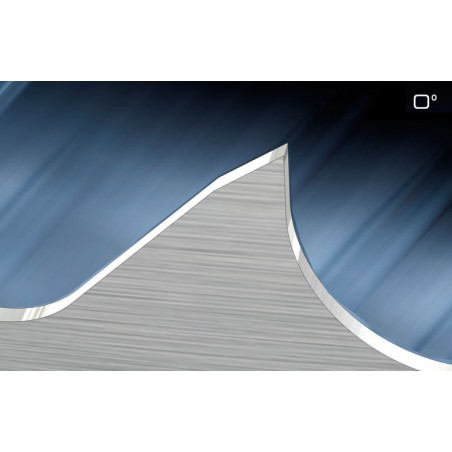

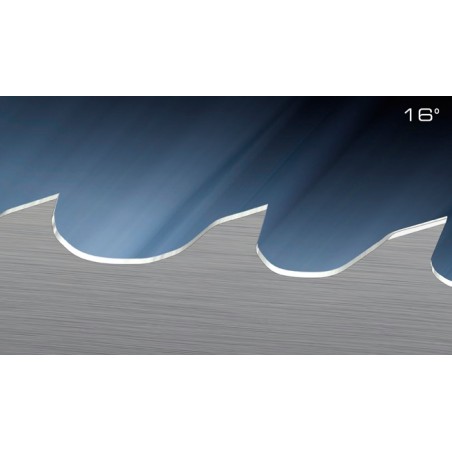

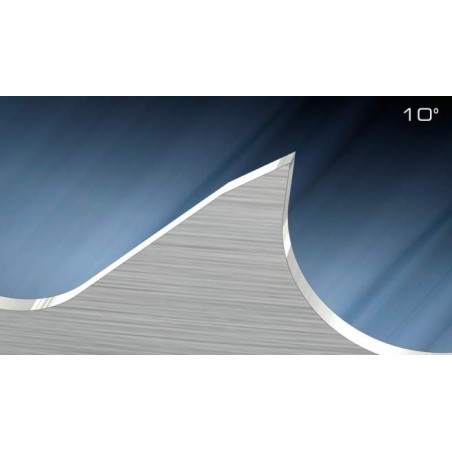

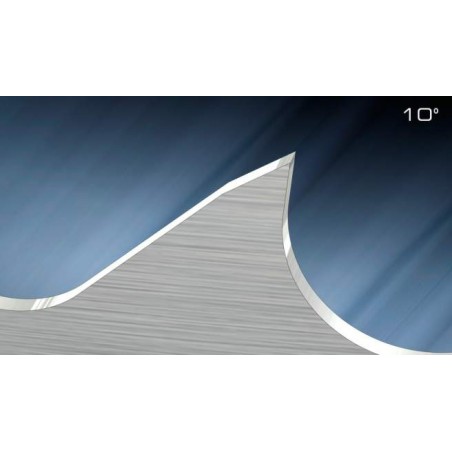

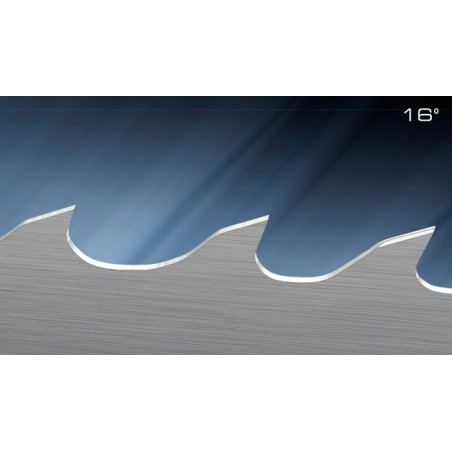

- Optimised tooth geometry – ensures efficient chip removal and low cutting forces.

Construction and technology

The Bi-Alfa Cobalt M51 blade is composed of two main components: a backing strip made of chromium-alloyed steel for flexibility, and a cutting edge made of HSS M51 high-speed steel. With increased cobalt and tungsten content, the teeth achieve higher hardness and superior tempering resistance, enabling effective operation at elevated temperatures. The flexible backing ensures excellent fatigue strength and stability during long-term industrial use, resulting in consistent performance and long service life.

Precision and performance

With an advanced tooth geometry and cutting edge hardness of 69–71 HRC, this blade can cut hard and high-alloy steels without premature wear. The RÖNTGEN M51 maintains its cutting performance under high load and heat conditions, making it ideal for cutting hardened, stainless, and acid-resistant steels. Reduced vibration and optimal chip evacuation contribute to smooth surface finishes and high cutting efficiency.

Applications

The RÖNTGEN Bi-Alfa Cobalt M51 Band Saw Blade is widely used in:

- Toolmaking industry – for cutting tool steels and high-speed steels,

- Machining of heat-resistant materials and stainless steels,

- Steel processing plants and foundries – for cutting alloy and structural steels,

- Precision manufacturing – for cutting materials difficult to machine conventionally,

- Fabrication and CNC workshops – for accurate and repeatable serial production.

Standard equipment

- HSS M51 cutting blade offering exceptional wear and heat resistance,

- Alloy steel backing with chromium addition,

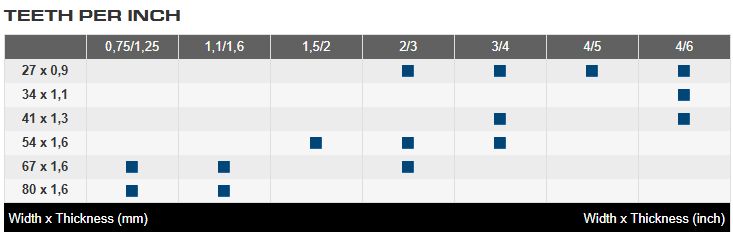

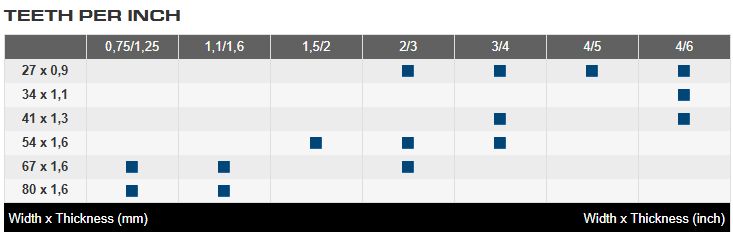

- Precisely ground variable-pitch teeth,

- Factory-welded joints ready for use in CORMAK and other bandsaws.

Optional equipment

- Variable tooth pitches (2/3, 3/4, 4/6 TPI) – adapted to material type,

- Custom blade lengths according to specific machine parameters,

- Special versions for titanium, Inconel, and nickel-based superalloys.

Technical data

| Parameter | Value |

|---|

| Type |

Bimetal HSS M51 |

| Tooth material |

HSS M51 (10% Co, with W addition) |

| Tooth hardness |

69–71 HRC |

| Backing material |

Alloy steel with chromium |

| Blade width |

13–41 mm |

| Blade thickness |

0.9–1.3 mm |

| Tooth pitch |

2/3 – 6/10 TPI (depending on version) |

| Applications |

Tool steel, stainless steel, acid-resistant alloys, hard-to-machine materials |

Choose a blade for demanding applications

If you need a metal-cutting blade capable of handling the toughest tasks – the RÖNTGEN Bi-Alfa Cobalt M51 Band Saw Blade delivers unmatched durability, stability, and cutting quality under extreme industrial conditions.

Order today and optimise your production for cutting high-strength, heat-resistant materials.

Write your review

* Required fields

I accept privacy policy rules