RÖNTGEN Bi-Alfa Profile Band Saw Blade – cutting blade for profiles, pipes, and sections

The RÖNTGEN Bi-Alfa Profile Band Saw Blade is a premium-quality cutting blade designed for cutting materials with variable cross-sections, such as pipes, steel profiles, and structural shapes. With its optimised tooth profile and reinforced geometry, this metal-cutting blade is ideal for operations involving impact loads and potential tooth edge chipping. It is perfectly suited for production plants, fabrication workshops, and automatic sawing systems.

Main advantages of the RÖNTGEN Bi-Alfa Profile bandsaw blade

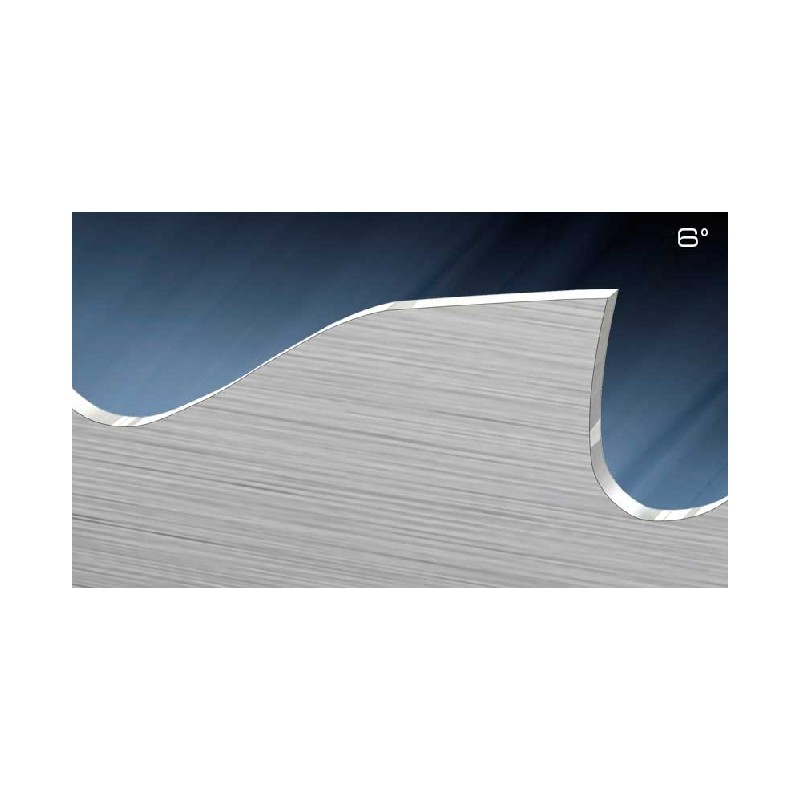

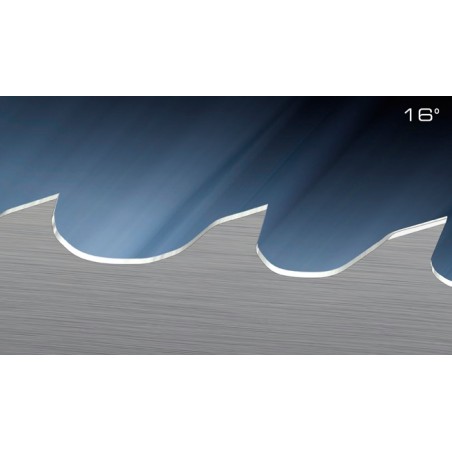

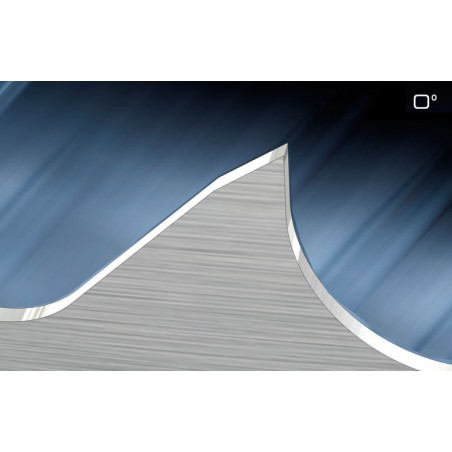

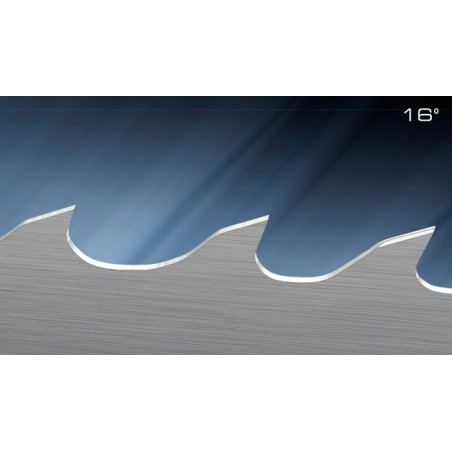

- Reinforced tooth profile – increased resistance to chipping when cutting thin-walled profiles and tubes.

- Bimetal construction – teeth made from HSS M42 steel with high wear and temperature resistance.

- Impact-resistant geometry – reduces microcracks and extends blade life.

- Accurate cutting without material deformation – optimised tooth design ensures a stable cutting line.

- High efficiency in continuous operation – suitable for automatic and semi-automatic bandsaws.

Construction and technology

The Bi-Alfa Profile cutting blade is built from two key components: a flexible alloy steel backing and a hardened tooth edge made of high-speed steel HSS M42 (containing 8% cobalt). This construction provides a perfect balance between fatigue resistance and tooth hardness. The special tooth geometry, designed for cutting hollow and thin-walled materials, guarantees safe, efficient cutting even in vibration-prone or deformable materials. The reinforced tooth back minimises the risk of damage when encountering sharp edges of the workpiece.

Precision and performance

The Bi-Alfa Profile model enables precise and rapid cutting of various metal shapes without loss of surface quality. The tooth structure minimises blade deflection, improves operational stability, and extends blade life between replacements. This results in reduced machine downtime and lower production costs in serial manufacturing environments.

Applications

The RÖNTGEN Bi-Alfa Profile metal-cutting blade is designed for:

- Cutting closed and open steel profiles,

- Machining thin-walled steel and aluminium tubes,

- Use in automatic and semi-automatic bandsaws,

- Structural steelwork and frame manufacturing,

- Toolmaking and metal fabrication workshops.

Standard equipment

- HSS M42 cutting blade with profiled teeth for impact resistance,

- Flexible, fatigue-resistant backing,

- Variable tooth pitch suited to different wall thicknesses,

- Factory-welded joints made to industrial standards, ready for installation.

Optional equipment

- Tooth pitches: 3/4, 4/6, 5/8 TPI – adapted to profile type and dimensions,

- Various blade lengths compatible with CORMAK saws and other manufacturers,

- Special versions for cutting stainless steel, aluminium, and non-ferrous metals.

Technical data

| Parameter | Value |

|---|

| Blade type |

Bimetal HSS M42 |

| Tooth material |

High-speed steel M42 (8% Co) |

| Tooth geometry |

Profiled, impact-resistant |

| Backing material |

Alloy spring steel |

| Blade width |

13 – 41 mm |

| Blade thickness |

0.9 – 1.3 mm |

| Tooth pitch |

3/4 – 5/8 TPI |

| Applications |

Pipes, steel profiles, sections, thin-walled metal materials |

Choose durability and performance when cutting profiles

If you are looking for a reliable cutting blade for machining profiles, pipes, and sections – the RÖNTGEN Bi-Alfa Profile Band Saw Blade is the perfect choice. With its reinforced tooth geometry and resistance to impact loads, this model offers long service life, low operating costs, and consistent cutting quality.

Order now and increase your cutting efficiency with proven RÖNTGEN performance.

Write your review

* Required fields

I accept privacy policy rules