RÖNTGEN HM-Titan forteC Band Saw Blade – Carbide-Tipped Cutting Blade for Hard-to-Machine Materials

RÖNTGEN HM-Titan forteC Metal Saw Blade is an advanced industrial-grade cutting blade with carbide (HM) teeth, developed for maximum efficiency and durability when cutting the hardest and most demanding materials. With its innovative design and special tooth coating, the forteC band ensures higher cutting performance and extended tool life, without requiring blade break-in. It is an irreplaceable solution for serial production under heavy load, where reliability, precision, and cutting speed are essential.

Main Advantages of the RÖNTGEN HM-Titan forteC Band Saw Blade

- Carbide (HM) teeth – provide maximum wear resistance and efficiency on hard materials.

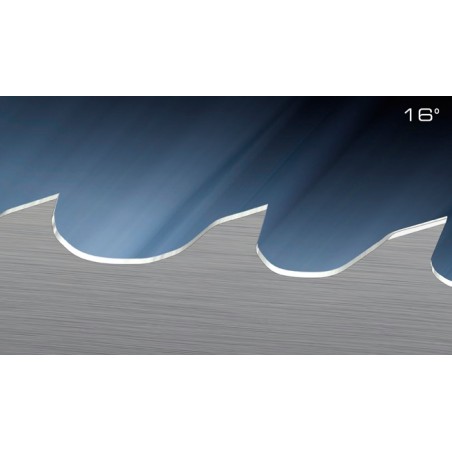

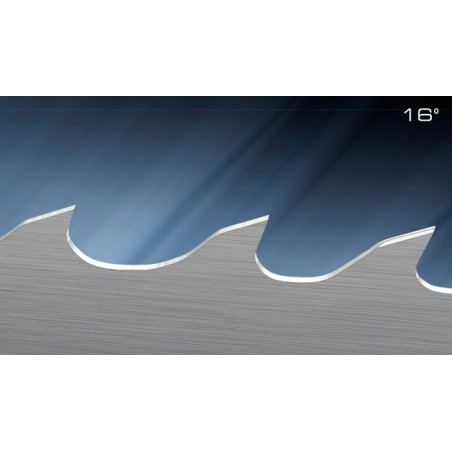

- Precision-mounted carbide inserts – set in spherically milled pockets and attached using electronically controlled welding.

- No need for blade break-in – full cutting capability from the first use.

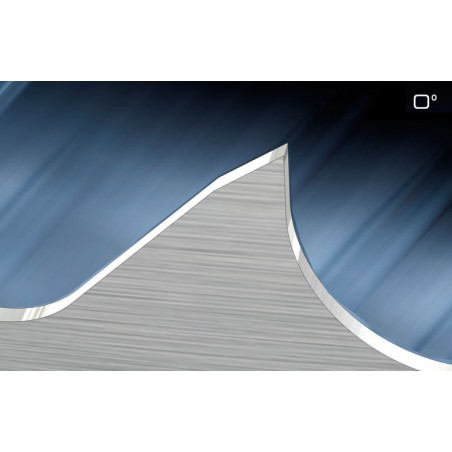

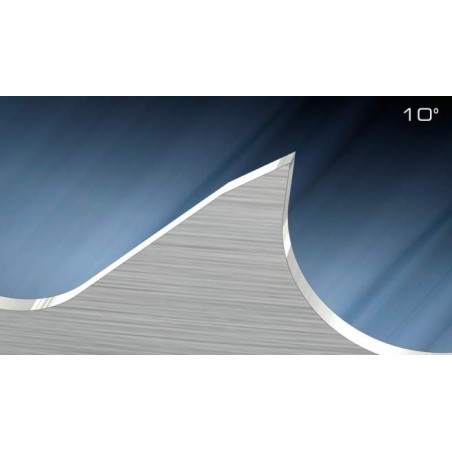

- Special tooth coating – reduces friction, increases tool life, and enables higher cutting speeds.

- Alloy backing band – highly resistant to fatigue and deformation under dynamic loads.

Construction and Technology

HM-Titan forteC is the result of advanced cutting engineering. Carbide inserts are placed in precision-milled spherical pockets and secured by electronically controlled welding. This ensures uniform force distribution and high stability of each insert during intensive operation. The innovative protective tooth coating not only reduces cutting resistance but also prevents material adhesion to the teeth, improving surface quality and reducing wear. The carrier is made of a fatigue-resistant special steel alloy, providing rigidity and long life when cutting hard-to-machine materials.

Precision and Performance

The RÖNTGEN HM-Titan forteC Metal Saw Blade delivers both high material removal rates and dimensional accuracy with superior surface finish. As it requires no break-in period, the operator receives a fully operational tool from the first use, which reduces setup time and lowers unit costs. The blade is ideal for continuous operation, offering high cutting speeds, repeatability, and overload resistance.

Applications

HM-Titan forteC Cutting Blade is designed for cutting:

- Hard-to-machine steels – including hardened, alloy, and tool steels,

- Superalloys – nickel, cobalt, and heat-resistant alloys,

- Forgings and metal blocks with large cross-sections,

- High-density and hardened components,

- Continuous industrial cutting – automated production lines.

Standard Equipment

- Carbide (HM) teeth with special geometry,

- Spherically milled seating pockets,

- Carrier band made of special steel alloy,

- Factory welds compatible with CORMAK and other industrial saws.

Optional Equipment

- Tooth pitches: 1.4/2 – 4/6 TPI,

- Band lengths compatible with CNC and semi-automatic band saws,

- Versions with coatings reducing material adhesion.

Technical Data

| Parameter | Value |

|---|

| Band type |

HM – with carbide tips |

| Tooth material |

Carbide (HM) |

| Backing band |

Special steel alloy |

| Mounting technology |

Milled pockets + controlled welding |

| Protective tooth coating |

Yes |

| Width range |

27 – 67 mm |

| Band thickness |

0.9 – 1.6 mm |

| Tooth pitch |

1.4/2 – 4/6 TPI |

| Application |

Hard-to-machine materials, precision cutting, heavy industry |

Choose Technology that Boosts Your Efficiency

If you need a reliable metal saw blade for cutting difficult materials and demanding applications, the RÖNTGEN HM-Titan forteC cutting blade is a premium-class solution. With no break-in required, long service life, and resistance to extreme working conditions, it ensures time savings and maximised productivity.

Order now and enhance your production efficiency with advanced cutting technology!

Write your review

* Required fields

I accept privacy policy rules