RÖNTGEN Bi-Alfa Cobalt WS Band Saw Blade – metal-cutting blade with an increased tooth set

The RÖNTGEN Bi-Alfa Cobalt WS Band Saw Blade is a specialised cutting blade engineered for stable operation in demanding industrial cutting environments. Using HSS M42 high-speed steel for the cutting edge and an enlarged tooth set, this metal-cutting blade performs exceptionally well when standard blades are prone to binding or overheating. It guarantees clean cutting, smooth chip evacuation, and long service life.

Main advantages of the RÖNTGEN Bi-Alfa Cobalt WS bandsaw blade

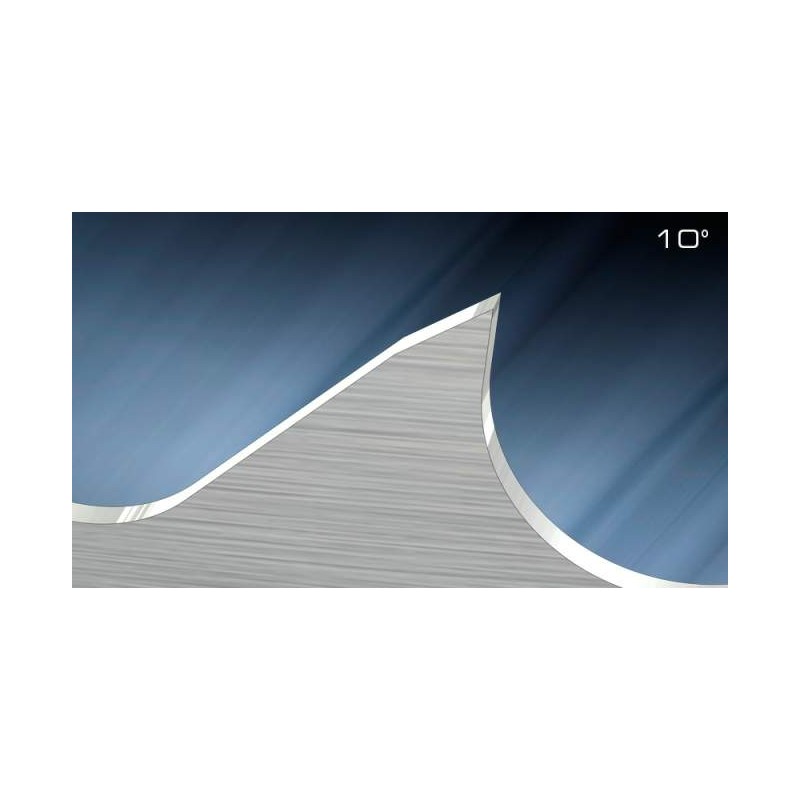

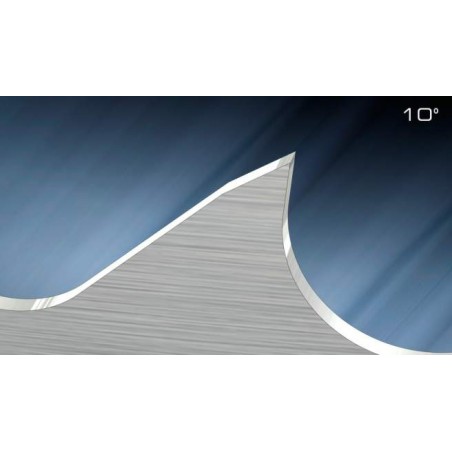

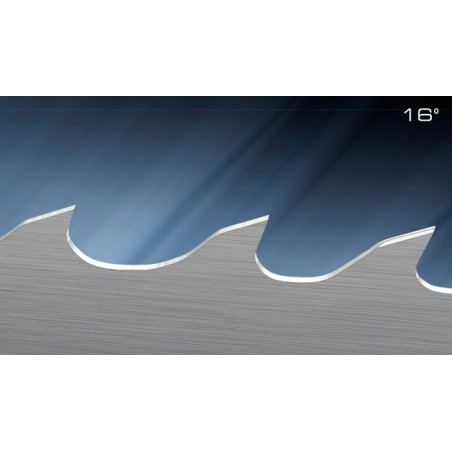

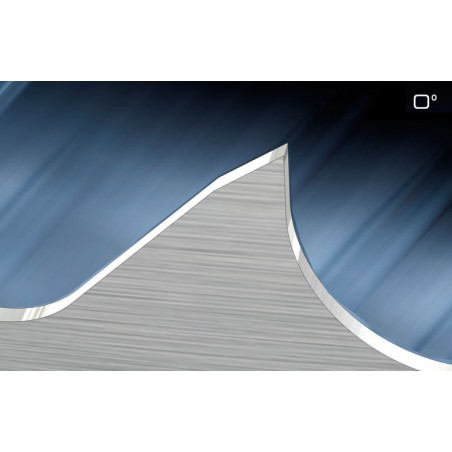

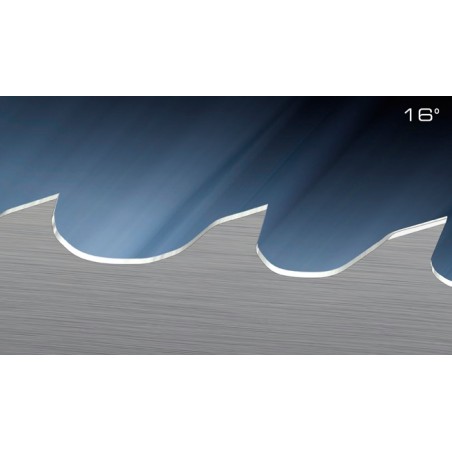

- Increased tooth set – provides a wider kerf to prevent blade binding within the workpiece.

- HSS M42 high-speed steel cutting edge – ensures superior wear and heat resistance.

- Excellent cutting process control – reduced friction, improved cooling, and cleaner surface finish.

- Durability and reliability – high resistance to micro-cracking and wear during long production cycles.

- Compatibility with CNC and semi-automatic bandsaws – ideal for a wide range of industrial applications.

Construction and technology

The RÖNTGEN Bi-Alfa Cobalt WS bandsaw blade was developed for cutting metals that generate high friction and heat during machining. The teeth, made from HSS M42 high-speed steel (8% cobalt), offer excellent hardness, wear, and heat resistance. The wider tooth set ensures smoother cutting with additional clearance, reducing the risk of blade binding. The alloy spring-steel backing provides flexibility and fatigue strength, ensuring long operational life even under heavy-duty conditions.

Precision and performance

Thanks to its unique tooth set, the WS model offers superior chip evacuation and reduced heat generation, resulting in stable performance and extended durability. This feature is particularly advantageous when cutting materials prone to sticking or generating friction during the cutting process. The blade maintains dimensional accuracy and cutting geometry throughout long production cycles without deformation or loss of sharpness.

Applications

The RÖNTGEN Bi-Alfa Cobalt WS Band Saw Blade is recommended for cutting:

- Structural, stainless, and alloy steels,

- Non-ferrous metals such as copper, aluminium, and brass,

- Thick-walled or closed-profile materials,

- Workpieces requiring protection against blade jamming,

- Series production processes in metalworking and fabrication industries.

Standard equipment

- HSS M42 cutting blade with increased tooth set,

- Spring-steel backing – durable and resistant to cracking,

- Factory-welded joints ready for immediate installation,

- Tooth geometry optimised for a wide range of materials and profiles.

Optional equipment

- Tooth pitches: 2/3, 3/4, 4/6 TPI – tailored to material thickness and type,

- Blade lengths compatible with CORMAK and other manufacturers’ bandsaws,

- Special versions for cutting stainless and hard-to-machine materials.

Technical data

| Parameter | Value |

|---|

| Blade type |

Bimetal HSS M42 |

| Tooth material |

High-speed steel M42 (8% Co) |

| Tooth set |

Increased – prevents blade jamming |

| Backing material |

Alloy spring steel |

| Blade width |

13 – 41 mm |

| Blade thickness |

0.9 – 1.3 mm |

| Tooth pitch |

2/3 – 4/6 TPI |

| Applications |

Structural steels, stainless steels, non-ferrous metals, anti-jamming cutting operations |

Choose reliability for challenging cutting conditions

The RÖNTGEN Bi-Alfa Cobalt WS Band Saw Blade is the perfect choice for production facilities demanding maximum durability, heat resistance, and stable cutting performance in hard-to-machine materials. The increased tooth set provides a clear technological advantage, especially where standard blades are not sufficient.

Order now and experience the cutting efficiency your production line deserves.

Write your review

* Required fields

I accept privacy policy rules