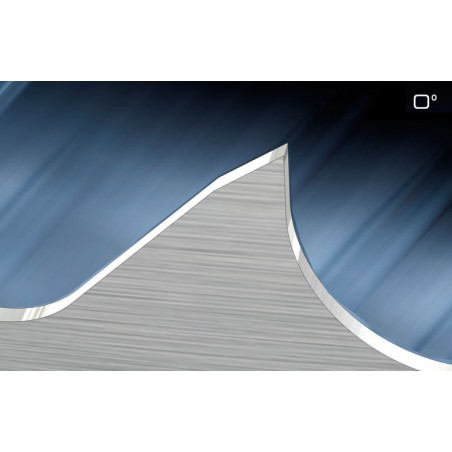

RÖNTGEN HM-Titan MU Band Saw Blade – Carbide-Tipped Cutting Blade for Hard and Difficult-to-Machine Metals

RÖNTGEN HM-Titan MU Metal Saw Blade is a high-performance industrial-grade cutting blade equipped with carbide (HM) teeth. Specifically designed for cutting hard and difficult-to-machine materials, this band saw blade stands out for its excellent durability, shorter cutting time, and superior surface quality. Thanks to optimised tooth geometry and high cutting speed, the HM-Titan MU excels wherever standard blades cannot keep up.

Main Advantages of the HM-Titan MU Band Saw Blade

- Carbide (HM) teeth – exceptional hardness and wear resistance.

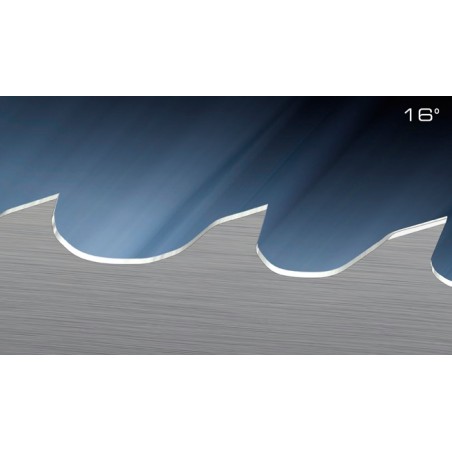

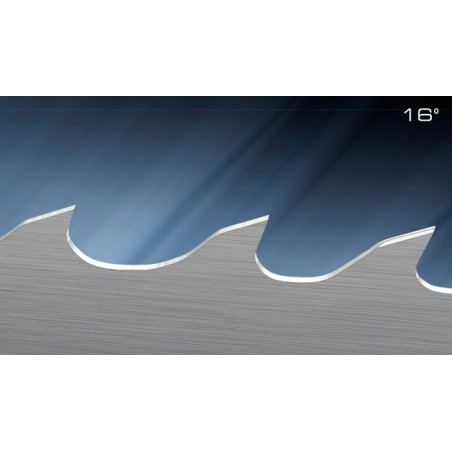

- Special tooth geometry – effective chip evacuation and noise reduction during operation.

- High cutting speed – shorter processing time while maintaining surface quality.

- Excellent cut quality – burr-free, clean, and even surface without the need for post-processing.

- Extended tool life – resistant to thermal and mechanical fatigue.

Construction and Technology

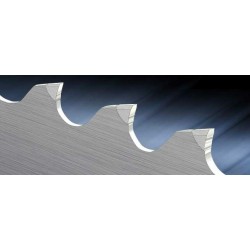

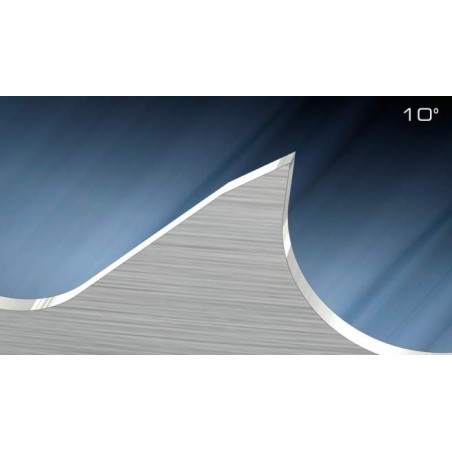

The RÖNTGEN HM-Titan MU cutting blade consists of a high-tensile, fatigue-resistant steel backing and carbide-tipped teeth brazed with precision. The tooth geometry is designed for efficient cutting of hard materials – variable rake angles provide better control of the cutting process. The shape of the teeth allows for rapid chip removal and reduced heat buildup, significantly increasing tool life and process stability.

Precision and Efficiency

The HM-Titan MU ensures stable, fast, and highly accurate cutting without material delamination. Thanks to its carbide teeth, it can machine very hard materials such as tool steels, hardened steels, stainless steels, and heat-resistant alloys. The band operates quietly and with minimal vibration, which is essential for serial cutting and automated systems. The high surface quality achieved after cutting reduces or eliminates the need for further finishing.

Applications

The RÖNTGEN HM-Titan MU Band Saw Blade is designed for cutting:

- Tool, hardened, and heat-treated steels,

- Stainless, acid-resistant, and duplex steels,

- Titanium, inconel, and other superalloys,

- High-efficiency serial production in metal processing plants,

- Automatic and semi-automatic band saws.

Standard Equipment

- Cutting blade with carbide-tipped teeth brazed onto a steel backing,

- Tooth geometry optimised for hard and difficult-to-machine materials,

- Factory welds allowing quick installation in band saws,

- Backing band with high tensile and crack resistance.

Optional Equipment

- Tooth pitches: 2/3, 3/4, 4/6 TPI – selected according to material type and size,

- Band lengths compatible with CORMAK and other industrial saws,

- Special versions for very thin or very thick cross-sections.

Technical Data

| Parameter | Value |

|---|

| Band type |

Bimetal with HM (carbide) teeth |

| Tooth material |

Carbide (HM) |

| Backing band |

Alloy spring steel |

| Tooth geometry |

Variable, optimised for chip removal and cutting quality |

| Band width |

27 – 67 mm |

| Band thickness |

0.9 – 1.6 mm |

| Tooth pitch |

2/3 – 4/6 TPI |

| Applications |

Difficult-to-machine materials, tool steels, stainless steels, superalloys |

Choose Reliability for Hard-Material Machining

By choosing the RÖNTGEN HM-Titan MU cutting blade with carbide-tipped teeth, you get a metal saw blade that meets the toughest cutting demands. Exceptional cutting performance, long life, and unmatched surface finish make it a premium solution for professional users.

Order now and improve the efficiency and precision of your cutting processes.

Write your review

* Required fields

I accept privacy policy rules