RÖNTGEN HM-Titan MUSN Band Saw Blade – Carbide-Tipped Cutting Blade for Hardened and Difficult-to-Machine Materials

RÖNTGEN HM-Titan MUSN Metal Saw Blade is a specialised band saw blade with carbide (HM) teeth designed for cutting materials exceeding 50 HRC in hardness, such as hardened, heat-treated, and induction-hardened steels. It is a dependable tool for heavy-duty machining where precision, durability, and heat resistance are essential. With its modern design and optimised tooth geometry, the MUSN blade guarantees exceptional cutting quality even in demanding industrial environments.

Main Advantages of the RÖNTGEN HM-Titan MUSN Band Saw Blade

- Carbide (HM) teeth – perfect for cutting materials with hardness above 50 HRC.

- Designed for heavy-duty use – excellent resistance to wear, microcracking, and overheating.

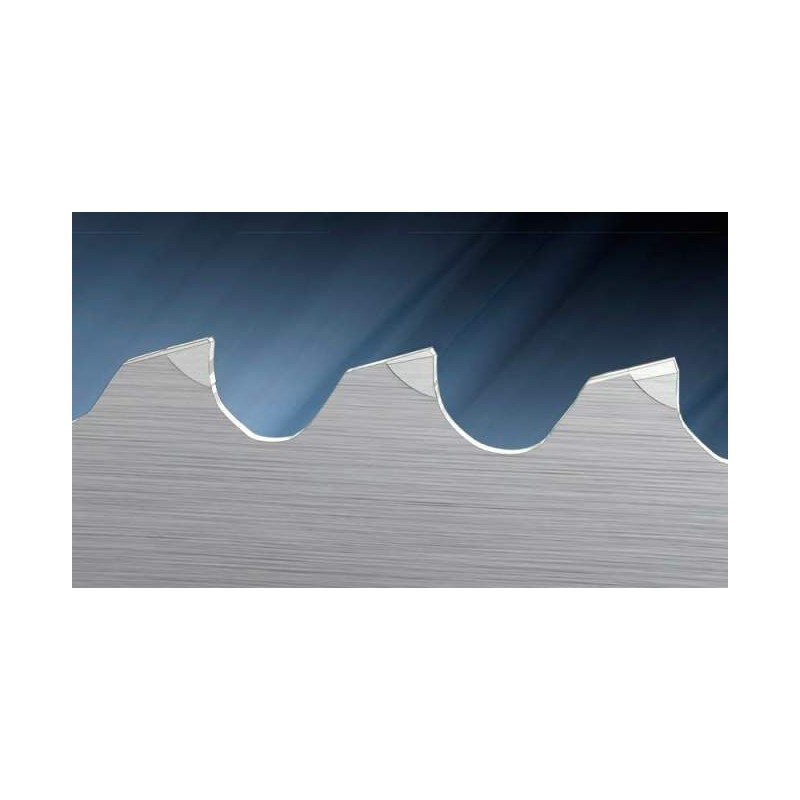

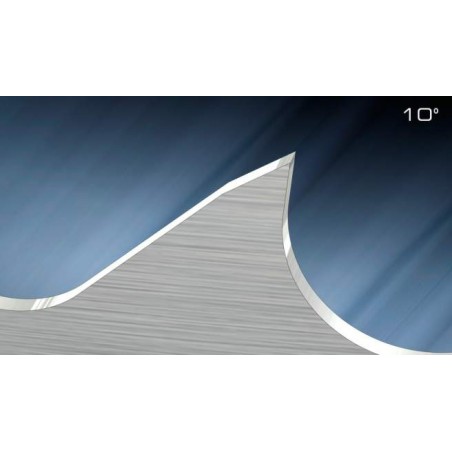

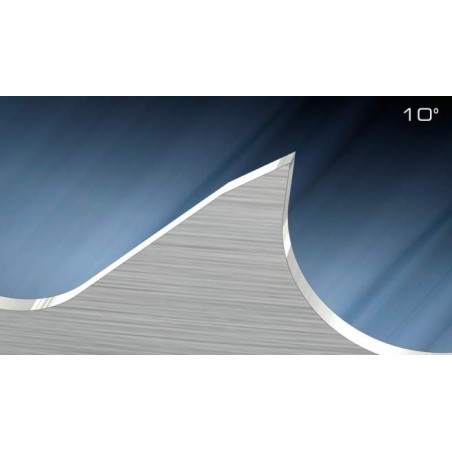

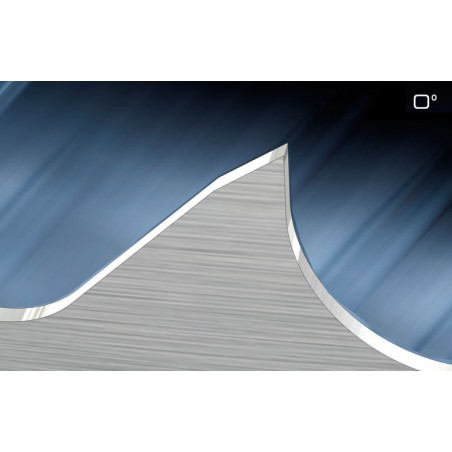

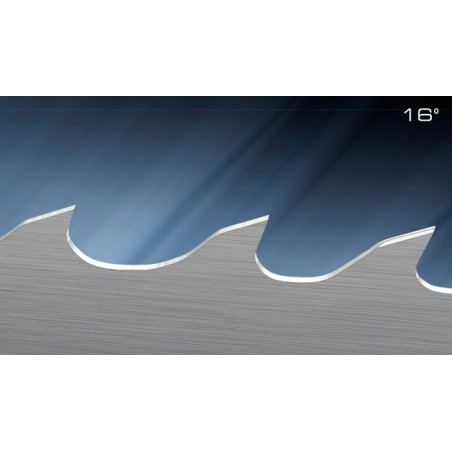

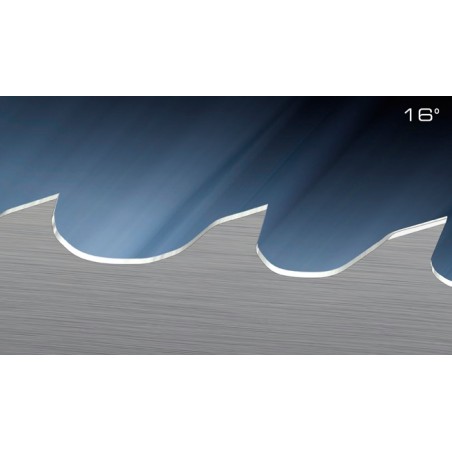

- Optimised tooth geometry – allows cutting hardened steels without deformation or tool damage.

- Stable and quiet operation – even at high speeds and on large cross-sections.

- Extended tool life – minimises downtime and reduces operating costs.

Construction and Technology

The RÖNTGEN HM-Titan MUSN cutting blade is built on a robust high-grade alloy steel backing with excellent fatigue resistance. The carbide teeth are precisely brazed to ensure durability under heavy dynamic loads. The tooth geometry is optimised for cutting hard materials, providing efficiency and safety – no jamming, overheating, or rebound effects. Its ability to operate at high cutting speeds and feeds makes it ideal for modern production environments demanding performance and consistency.

Precision and Performance

The HM-Titan MUSN delivers exceptional quality and repeatability in cutting high-hardness materials. This metal saw blade ensures a smooth, burr-free surface, low energy consumption, and significantly reduced cutting times. It is the perfect solution for professionals requiring maximum productivity in serial production and precision in individual operations. The blade performs equally well in both straight and angled cuts, maintaining linear accuracy and minimising material waste.

Applications

RÖNTGEN HM-Titan MUSN Cutting Blade is recommended for cutting:

- Hardened and heat-treated steels,

- Induction-hardened materials,

- High-hardness superalloys,

- Large-section components requiring stable cutting,

- Tool steels, dies, and forgings.

Standard Equipment

- Carbide (HM) teeth brazed onto the steel backing,

- Tooth geometry adapted for materials above 50 HRC,

- Fatigue- and tension-resistant alloy steel backing,

- Factory welds compatible with CORMAK and other industrial saws.

Optional Equipment

- Tooth pitches: 1.4/2 – 4/6 TPI depending on material and section,

- Length options suitable for CNC, automatic, and semi-automatic band saws,

- Optional surface coatings to enhance durability and reduce friction.

Technical Data

| Parameter | Value |

|---|

| Band type |

Carbide-tipped (HM) |

| Tooth material |

Carbide (HM) |

| Backing band |

Alloy spring steel |

| Tooth geometry |

Optimised for hard materials (≥ 50 HRC) |

| Band width |

27 – 67 mm |

| Band thickness |

0.9 – 1.6 mm |

| Tooth pitch |

1.4/2 – 4/6 TPI |

| Applications |

Hardened steels, dies, forgings, hard-to-machine materials |

Choose Premium Quality for Hardened Steel Cutting

If you need a metal saw blade that offers reliability and long service life when machining the hardest materials, the RÖNTGEN HM-Titan MUSN is the perfect choice. It is a cutting blade for professionals seeking high productivity, precision, and safe operation.

Order now and increase your production efficiency with this premium-grade tool.

Write your review

* Required fields

I accept privacy policy rules