RÖNTGEN HM-Titan ALU3 Band Saw Blade – Carbide-Tipped Cutting Blade for Aluminium and Non-Ferrous Metals

RÖNTGEN HM-Titan ALU3 Metal Saw Blade is a technologically advanced industrial-grade cutting blade with carbide (HM) teeth, designed specifically for cutting aluminium and other non-ferrous metals. Thanks to innovative tooth geometry and a reinforced alloy-steel backing, HM-Titan ALU3 ensures exceptional cutting performance, process stability, and tool durability. It is ideal for cutting profiles, plates, bars, and castings, even under increased load and cutting speed.

Main Advantages of the RÖNTGEN HM-Titan ALU3 Band Saw Blade

- Carbide (HM) teeth – deliver maximum wear resistance and high cutting efficiency.

- Special tooth geometry – prevents insert loss under intense vibration conditions.

- Reinforced backing band – resistant to fatigue and mechanical stress.

- Optimised for non-ferrous metals – perfect for aluminium, copper, bronze, and their alloys.

- Extended tool life – significantly reduces operating costs and production downtime.

Construction and Technology

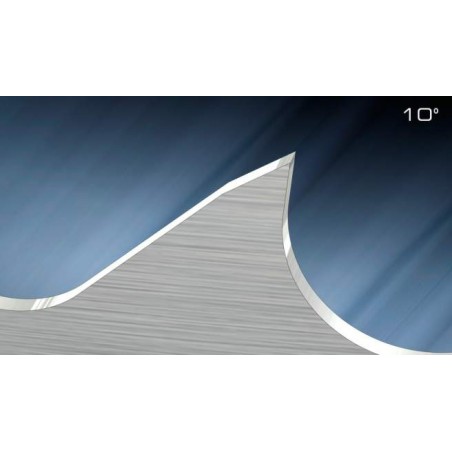

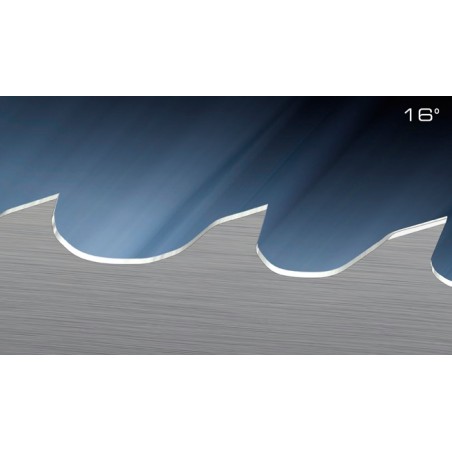

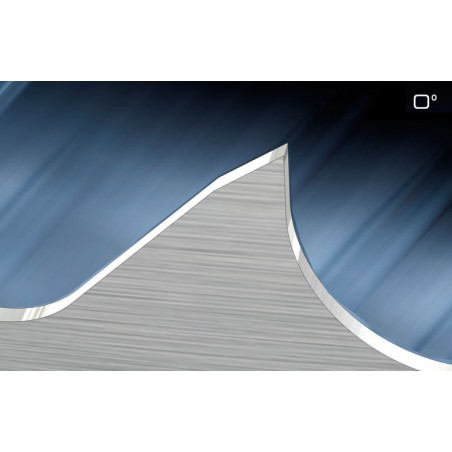

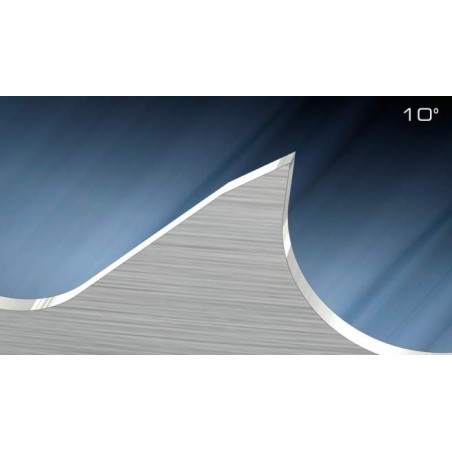

The HM-Titan ALU3 cutting blade combines carbide technology with the strength of spring steel. The carbide tips are brazed onto the backing band to ensure high resistance to detachment under strong vibration – such as when cutting rough castings. The optimised tooth geometry promotes efficient chip evacuation and prevents jamming, enhancing both safety and cutting continuity. The alloy-steel backing is fatigue-resistant, enabling high-speed and high-feed operation without compromising mechanical integrity.

Precision and Performance

The RÖNTGEN HM-Titan ALU3 Metal Saw Blade ensures high cutting quality without burns, deformation, or excessive heating of the material. Even in continuous operation, it maintains geometric stability, minimises vibration, and provides smooth guidance. The result is a clean surface finish and reduced total cycle time for both single and batch cutting.

Applications

RÖNTGEN HM-Titan ALU3 Cutting Blade is designed for cutting:

- Aluminium and its alloys – blocks, castings, profiles, plates, bars,

- Non-ferrous metals – copper, bronze, brass,

- Raw and semi-finished castings – of light and coloured materials,

- Large cross-sections – ideal for high-speed cutting requirements,

- Automatic and semi-automatic band saws.

Standard Equipment

- Carbide (HM) teeth with optimised geometry,

- Fatigue- and vibration-resistant alloy-steel backing,

- Tooth design adapted for non-ferrous materials,

- Factory welds – ready for immediate installation.

Optional Equipment

- Tooth pitches: 2/3, 3/4, 4/6 TPI – selected based on material type and cross-section,

- Band lengths compatible with CORMAK and other industrial saws,

- Special versions with anti-adhesive coatings for dry cutting.

Technical Data

| Parameter | Value |

|---|

| Band type |

Carbide-tipped (HM) |

| Tooth material |

Carbide (HM) |

| Backing band |

Alloy spring steel |

| Tooth geometry |

Anti-vibration, optimised for non-ferrous metals |

| Band width |

27 – 67 mm |

| Band thickness |

0.9 – 1.6 mm |

| Tooth pitch |

2/3 – 4/6 TPI |

| Applications |

Aluminium, non-ferrous metals, castings, profiles, plates, bars |

Increase Efficiency and Durability in Aluminium Cutting

If you are looking for a metal saw blade capable of handling intensive aluminium and non-ferrous metal machining, the RÖNTGEN HM-Titan ALU3 is your best choice. With durable carbide teeth, optimised tooth geometry, and resistance to mechanical overload, the ALU3 cutting blade guarantees precise cutting, shorter operation time, and extended tool life.

Order now and boost productivity and reliability in your cutting operations.

Write your review

* Required fields

I accept privacy policy rules