Bimetal Band Saw Blade RÖNTGEN Grit with Segment Coating – Precision Cutting Blade for Abrasive Cutting

RÖNTGEN Grit Segment-Coating Metal Saw Blade is a specialist cutting blade designed for cutting materials that do not produce chips, such as technical ceramics, composites, graphite, or plastics. The segmented carbide coating enables aggressive yet controlled grinding, ensuring high efficiency and consistent cutting quality. Thanks to its segmented structure, the band effectively dissipates heat and prevents clogging during the processing of challenging materials.

Main Advantages of the RÖNTGEN Grit Segment-Coating Bimetal Blade

- Segmented carbide coating – optimised grain distribution for efficient, aggressive cutting.

- Abrasive cutting without chip formation – ideal for brittle, porous, or sintered materials.

- Bidirectional operation – allows effective cutting in both directions of the band movement.

- High wear resistance – extended service life and lower operating costs.

- Precise edge finish – minimal finishing required after cutting.

Construction and Technology

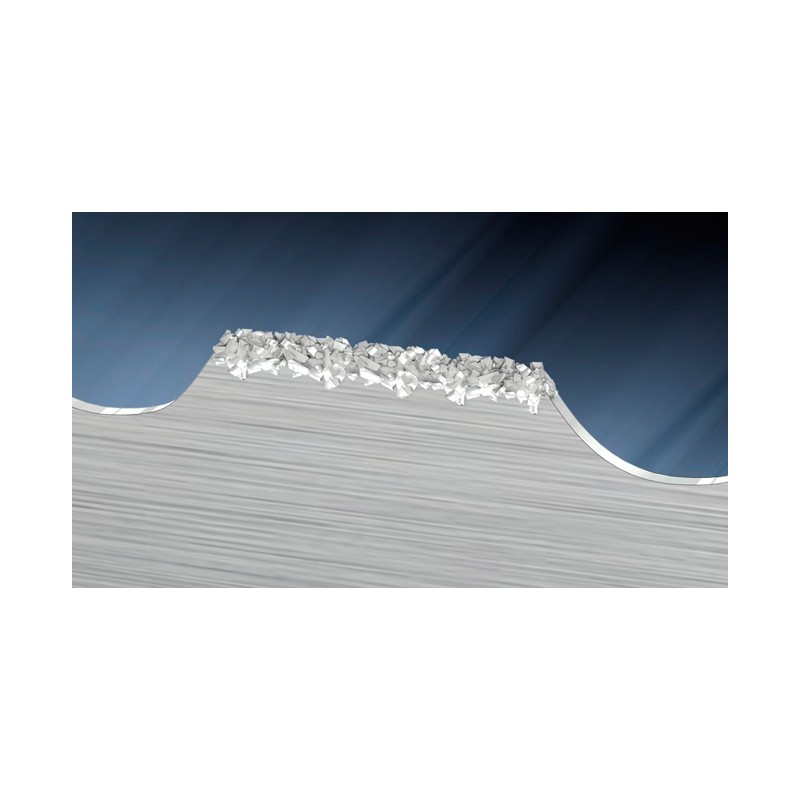

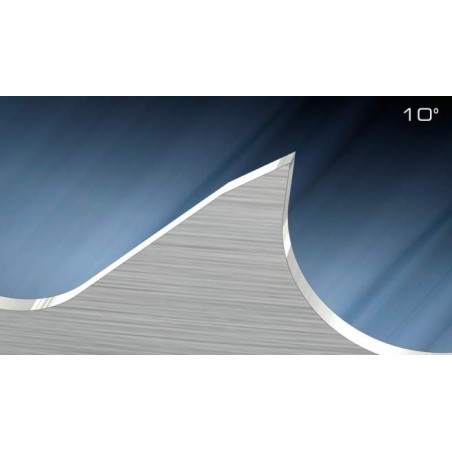

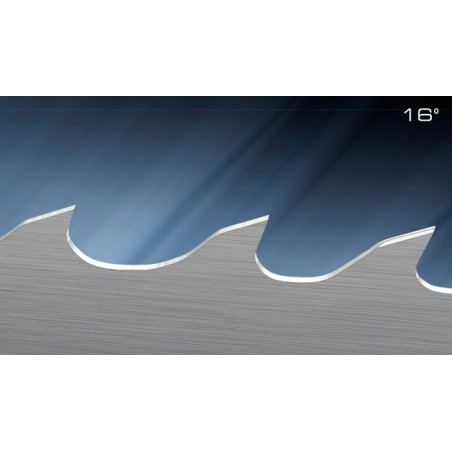

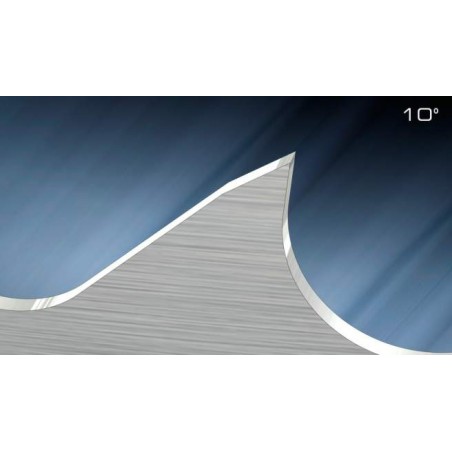

The RÖNTGEN Grit cutting blade with segmented coating is designed for heavy thermal and mechanical load conditions. The backing band is made of hardened bimetal steel, resistant to material fatigue and stretching. Its surface features a segmented coating of cemented carbide – precisely arranged in interrupted working zones to enhance cooling and debris removal. This structure allows cutting at higher speeds and pressures while maintaining cutting accuracy and tool durability. The segmented coating reduces the risk of overheating and clogging when cutting dense or porous materials.

Precision and Performance

The abrasive cutting technique using a segmented coating ensures a uniform and clean cutting edge even for materials that are difficult to machine. The open segment layout improves dust extraction and prevents material build-up on the band. The RÖNTGEN Grit metal saw blade offers high operational efficiency and enables long, continuous use without loss of sharpness. It performs excellently in both single-piece and serial production, wherever precision and repeatability are essential.

Applications

RÖNTGEN Grit with segment coating is particularly recommended for cutting:

- Technical composites (CFRP, GFRP),

- Ceramics and refractory ceramics,

- Graphite, porous and insulating materials,

- Plastics, technical foams,

- Non-ferrous and thin-walled metals.

Standard Equipment

- Segmented carbide coating – grit with defined gradation and spacing,

- Hardened backing band with high fatigue resistance,

- Available in widths from 6 mm to 67 mm,

- Lengths compatible with manual and automatic band saws.

Optional Equipment

- Selection of grit size (e.g. grit 60, 80, 120) depending on material type,

- Possibility to order bands with customised segment spacing,

- Special anti-adhesive or heat-resistant coatings available on request.

Technical Data

| Parameter | Value |

|---|

| Band type |

Bimetal with segmented carbide coating |

| Cutting method |

Abrasive, chip-free |

| Operation type |

Bidirectional band motion |

| Width range |

6 – 67 mm |

| Thickness range |

0.6 – 1.6 mm |

| Coating type |

Segmented (Grit 60–120) |

| Band material |

Bimetal steel + carbide coating |

| Working speed |

up to 1,500 m/min |

Choose Performance and Precision – Choose RÖNTGEN Grit Segment

Looking for a reliable solution for cutting challenging or brittle materials? The RÖNTGEN Grit cutting blade with segment coating is a metal saw blade and more – a tool dedicated to modern industry, where quality, stability, and durability matter. Choose a band that meets the demands of the most advanced production processes.

Order now and boost the efficiency of your cutting operations with proven CORMAK solutions.

Write your review

* Required fields

I accept privacy policy rules