RÖNTGEN HM-Titan B0 Band Saw Blade – Carbide-Tipped Cutting Blade for Hardened and Heat-Treated Steels

RÖNTGEN HM-Titan B0 Metal Saw Blade is an industrial-grade cutting blade equipped with carbide (HM) teeth, designed for cutting steels with hardness above 50 HRC. Perfect for induction-hardened and heat-treated materials, the HM-Titan B0 band provides high cutting efficiency, wear resistance, and excellent stability even under the most demanding conditions. This is a premium-class tool for industrial applications where durability, precision, and process reliability are key.

Main Advantages of the RÖNTGEN HM-Titan B0 Band Saw Blade

- Carbide (HM) tips – outstanding resistance to wear and high working temperatures.

- Designed for hard materials – ideal for hardened and heat-treated steels.

- Stability and precision – ensures straight, accurate cutting even on large cross-sections.

- High performance without compromise – reduced cutting time, lower tool wear, no run-in required.

- Durable backing band – alloy steel with high fatigue and overload resistance.

Construction and Technology

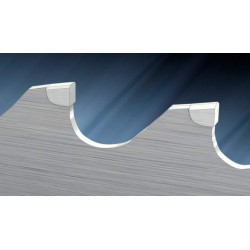

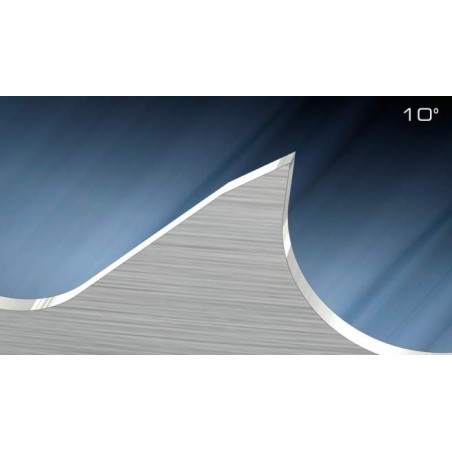

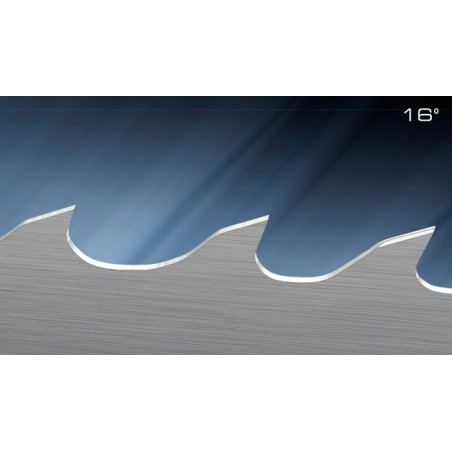

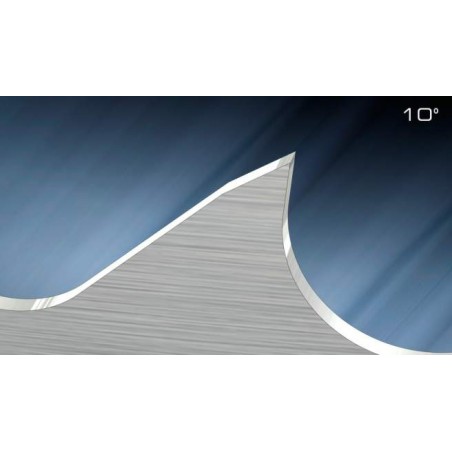

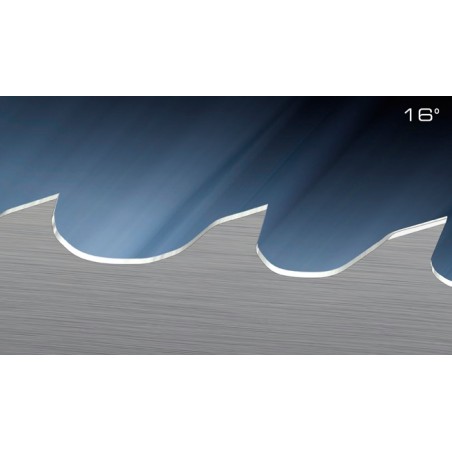

HM-Titan B0 is an advanced metal saw blade developed for demanding industrial environments. Each tooth is equipped with a brazed carbide insert that provides exceptional cutting performance and resistance to microcracking or chipping. The inserts are securely fixed to withstand intensive use and the cutting of very hard materials. The backing band, made from high-tensile, fatigue-resistant alloy steel, maintains its geometry under heavy stress. This technology ensures long service life and reliable performance, even in continuous operation.

Precision and Performance

The RÖNTGEN HM-Titan B0 cutting blade enables precise, fast, and safe cutting of hardened and difficult-to-machine materials. With optimised tooth geometry and excellent heat dissipation, it delivers high surface quality while reducing the risk of thermal deformation. The band runs smoothly without vibration, ensuring uniform results even during intensive use. It is perfectly suited for serial production, where every cutting cycle and material saving matters.

Applications

RÖNTGEN HM-Titan B0 Cutting Blade is recommended for cutting:

- Hardened and heat-treated steels (hardness > 50 HRC),

- Induction-hardened materials,

- Tool and high-speed steels,

- High-density, hard components,

- Large cross-sections – shafts, bars, dies, forgings.

Standard Equipment

- Carbide (HM) teeth brazed to the steel backing,

- Backing band made of special alloy steel,

- Factory welds compatible with CORMAK and other industrial saws,

- Tooth geometry adapted for hard and difficult-to-machine materials.

Optional Equipment

- Various tooth pitches (1.4/2 – 4/6 TPI) matched to material thickness and type,

- Band lengths suitable for manual, semi-automatic, and automatic saws,

- Special surface coatings for use under increased friction conditions.

Technical Data

| Parameter | Value |

|---|

| Band type |

Carbide-tipped (HM) |

| Tooth material |

Carbide |

| Backing band |

Alloy spring steel |

| Workpiece hardness |

Above 50 HRC |

| Band width |

27 – 67 mm |

| Band thickness |

0.9 – 1.6 mm |

| Tooth pitch |

1.4/2 – 4/6 TPI |

| Applications |

Hardened steel, heat-treated materials, difficult-to-machine alloys |

Choose Technology for the Toughest Tasks

If your production requires cutting high-hardness materials and you expect reliability, productivity, and long tool life, the RÖNTGEN HM-Titan B0 Metal Saw Blade is the ideal choice. Increase efficiency and safety in your operations by investing in a cutting blade built for the most demanding applications.

Order now and gain a competitive edge with professional CORMAK cutting solutions.

Write your review

* Required fields

I accept privacy policy rules