RÖNTGEN Bi-Alfa Cobalt RP Band Saw Blade – high-performance cutting blade with aggressive tooth geometry

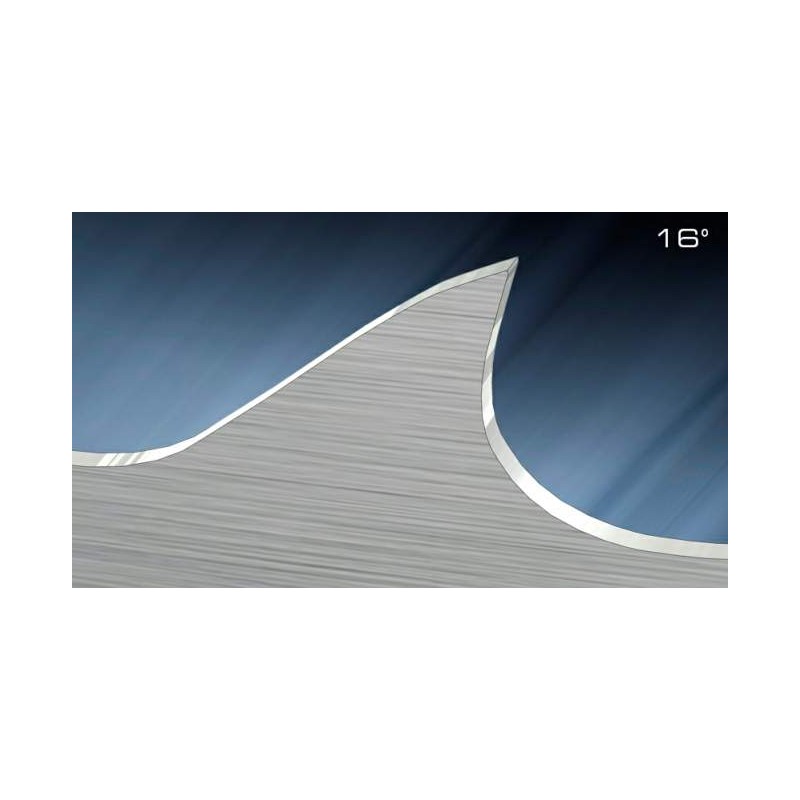

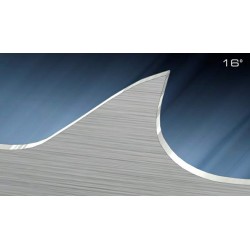

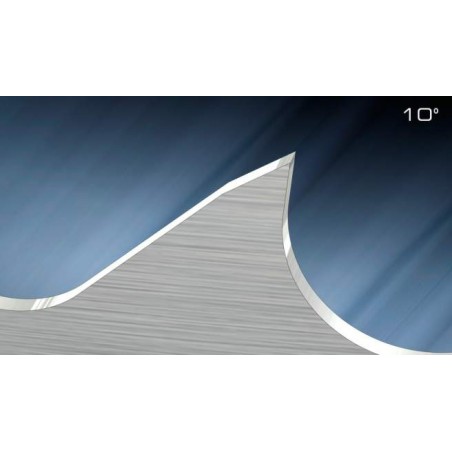

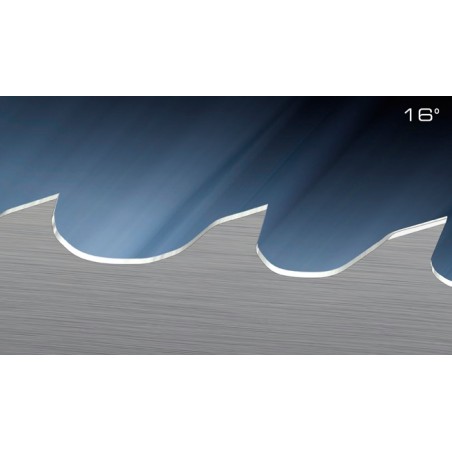

The RÖNTGEN Bi-Alfa Cobalt RP Band Saw Blade is a specialised cutting blade engineered for rapid and efficient cutting of difficult-to-machine materials. Building upon the trusted M42 construction, the RP version features an aggressive 16° rake angle that enhances cutting speed and chip removal. This metal-cutting bandsaw blade is designed for industrial environments where durability, precision, and productivity are key factors.

Main advantages of the RÖNTGEN Bi-Alfa Cobalt RP bandsaw blade

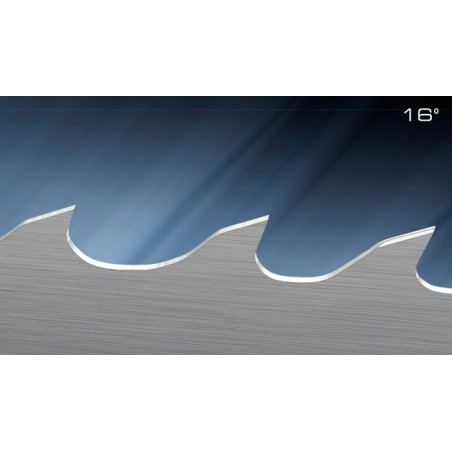

- 16° aggressive rake angle – ensures efficient penetration and fast cutting rates.

- Hardened HSS M42 teeth – deliver excellent wear and heat resistance when cutting alloy and stainless steels.

- Improved chip evacuation – minimises clogging and overheating during long-term operation.

- Extended blade life – optimised tooth geometry enhances durability and stability under load.

- Reliable operation in automatic and semi-automatic machines – precise and repeatable cuts in serial production.

Construction and technology

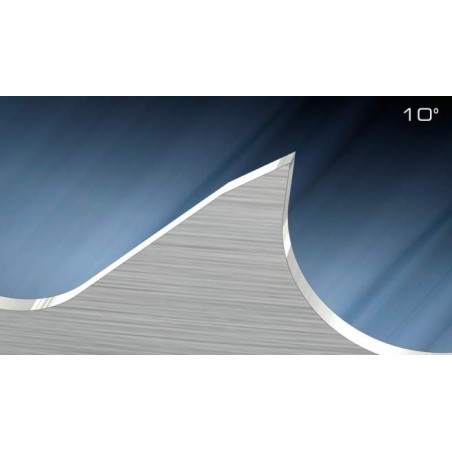

The Bi-Alfa Cobalt RP cutting blade is built upon the proven M42 design, upgraded with a 16° rake angle for enhanced performance. Its aggressive tooth profile enables effective cutting of high-strength and dense materials. The teeth are made from HSS M42 high-speed steel containing 8% cobalt for improved thermal and wear resistance. The flexible spring-steel backing provides elasticity and fatigue strength – essential for intensive industrial operation and long service life.

Precision and performance

The RÖNTGEN RP blade combines cutting performance with controlled tooth geometry. Despite its aggressive profile, it maintains high accuracy – producing clean cuts with smooth surfaces that require minimal finishing. Efficient chip evacuation prevents heat build-up and enhances continuous-cutting stability. This blade is highly recommended for automatic and CNC band saws, where stability, longevity, and cutting speed are crucial for production efficiency.

Applications

The Bi-Alfa Cobalt RP metal-cutting blade is ideal for cutting:

- Stainless and acid-resistant steels,

- Tool and high-alloy steels,

- Solid metal profiles and bar materials,

- High-density metallurgical components,

- Mass and medium-series production parts in industrial environments.

Standard equipment

- HSS M42 cutting blade with RP geometry (16° rake angle),

- Spring-steel backing – flexible and crack-resistant,

- Factory-welded joints for immediate installation,

- Profiled teeth for cutting high-hardness materials.

Optional equipment

- Tooth pitches: 2/3, 3/4, 4/6 TPI – depending on material type and thickness,

- Blade lengths compatible with CORMAK and other manufacturer band saws,

- Special versions for titanium, Inconel, Duplex, and other hard-to-machine alloys.

Technical data

| Parameter | Value |

|---|

| Blade type |

Bimetal HSS M42 |

| Rake angle |

16° (RP – Rapid Performance) |

| Tooth material |

High-speed steel M42 (8% Co) |

| Backing material |

Alloy spring steel |

| Blade width |

13 – 41 mm |

| Blade thickness |

0.9 – 1.3 mm |

| Tooth pitch |

2/3 – 4/6 TPI |

| Applications |

Alloy steel, stainless steel, solid and dense materials |

Choose efficiency and durability for demanding cutting operations

If your goal is fast and reliable metal cutting without compromising tool life or precision, the RÖNTGEN Bi-Alfa Cobalt RP Band Saw Blade is designed to meet the demands of modern industry. Its aggressive rake angle, wear-resistant M42 steel, and optimised tooth geometry deliver maximum cutting efficiency in the most challenging production environments.

Order now and optimise your cutting process with the industrial-grade Bi-Alfa RP blade.

Write your review

* Required fields

I accept privacy policy rules