RÖNTGEN Bi-Alfa Cobalt WS ALU Band Saw Blade – cutting blade for aluminium and non-ferrous metals

The RÖNTGEN Bi-Alfa Cobalt WS ALU Band Saw Blade is an advanced cutting blade engineered for precise cutting of non-ferrous metals – including aluminium, copper, brass, and their alloys. With the use of HSS M42 high-speed steel, a widened tooth set, and an aggressive rake angle, the WS ALU metal-cutting blade ensures efficient chip evacuation, minimises the risk of blade binding, and provides long-lasting durability even during continuous production cycles.

Main advantages of the RÖNTGEN Bi-Alfa WS ALU bandsaw blade

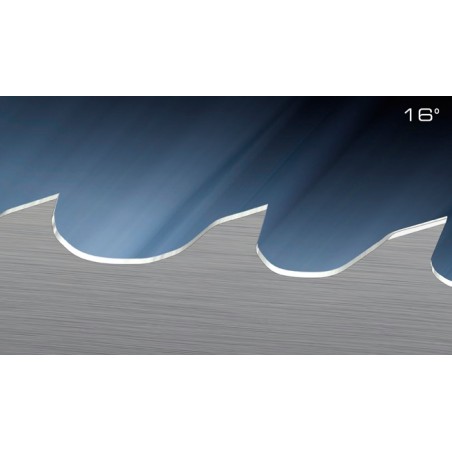

- Wide tooth set – increased kerf for excellent chip clearance and reduced clogging.

- Aggressive rake angle – ensures smooth penetration into soft, ductile non-ferrous metals.

- High wear resistance – achieved with HSS M42 (8% cobalt) cutting edges.

- Optimised tooth geometry – delivers uniform cutting and reduced cutting resistance.

- Extended blade life – minimises material adhesion and overheating during continuous use.

Construction and technology

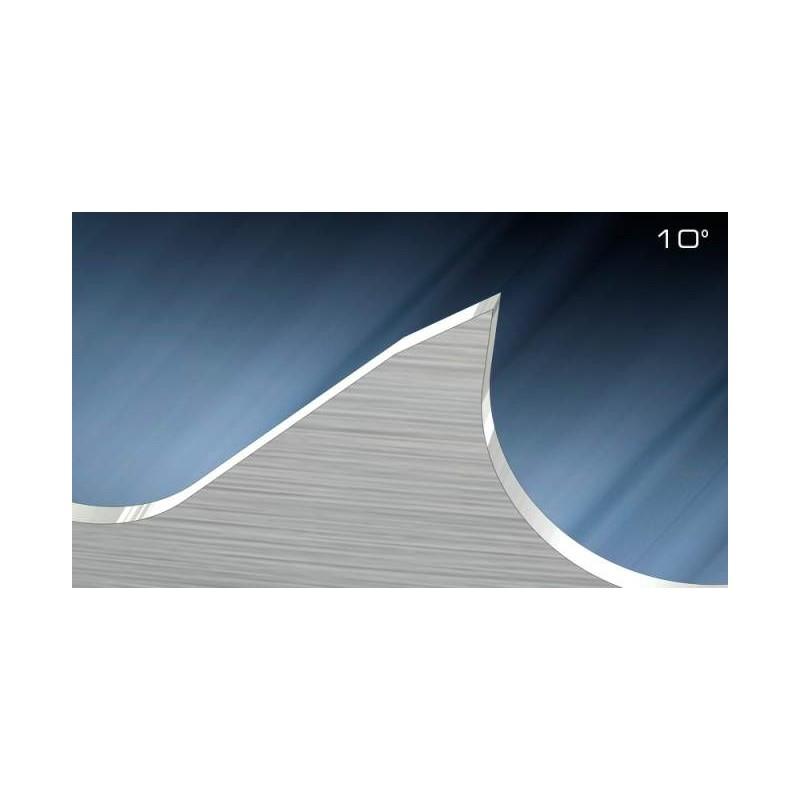

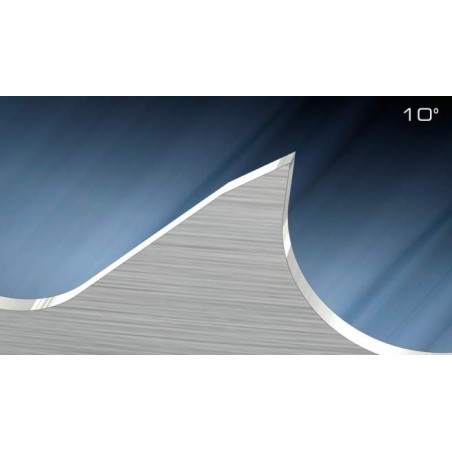

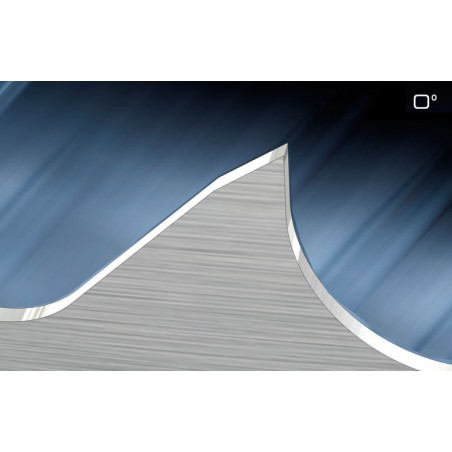

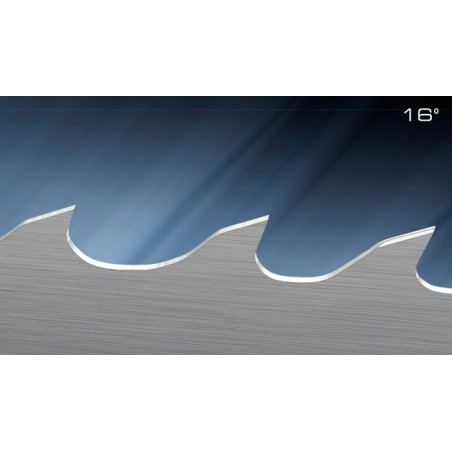

The WS ALU blade was designed specifically for cutting non-ferrous metals that tend to stick to the teeth and cause clogging. The working section is made of HSS M42 high-speed steel, providing excellent hardness and heat resistance for consistent edge retention. The widened tooth set creates a larger cutting channel, reducing the risk of binding and improving chip evacuation. The aggressive rake angle allows for smooth penetration into soft alloys without excessive feed force – essential when cutting lightweight, ductile materials.

Precision and performance

The WS ALU cutting blade delivers fast, clean cuts while reducing friction and heat build-up. The optimised tooth geometry and wear-resistant materials ensure stable operation in long production runs. Resistance to chip adhesion and lower cutting forces directly translate into lower energy consumption and longer tool life between replacements.

Applications

The RÖNTGEN WS ALU Band Saw Blade is recommended for:

- Cutting aluminium and aluminium alloys – blocks, profiles, bars, and castings,

- Processing copper, brass, and other non-ferrous metals,

- Aerospace, automotive, and electrical industries,

- Production facilities machining light and ductile materials,

- Automatic and semi-automatic band saw machines.

Standard equipment

- HSS M42 cutting blade with widened tooth set,

- Tooth geometry optimised for soft metal cutting,

- High-fatigue-resistant spring-steel backing,

- Factory-welded and ready-to-install bandsaw blades.

Optional equipment

- Tooth pitches: 2/3, 3/4, 4/6 TPI – depending on section size and material type,

- Blade lengths compatible with CORMAK and other brands’ saws,

- Special versions for high-speed cutting or thermally demanding applications.

Technical data

| Parameter | Value |

|---|

| Blade type |

Bimetal HSS M42 |

| Tooth material |

High-speed steel M42 (8% Co) |

| Tooth geometry |

Increased set, aggressive rake angle |

| Backing material |

Alloy spring steel |

| Blade width |

13 – 41 mm |

| Blade thickness |

0.9 – 1.3 mm |

| Tooth pitch |

2/3 – 4/6 TPI |

| Applications |

Aluminium, copper, brass, light and non-ferrous metals |

Achieve durability and efficiency when cutting non-ferrous metals

If you need a cutting blade for professional aluminium and non-ferrous metal cutting, the RÖNTGEN Bi-Alfa Cobalt WS ALU Band Saw Blade guarantees outstanding performance, reliability, and surface quality. Its design – optimised for fast chip evacuation and long lifespan – enables uninterrupted, cost-effective production.

Order today and boost your cutting efficiency with RÖNTGEN’s precision-engineered WS ALU bandsaw blade.

Write your review

* Required fields

I accept privacy policy rules