Bimetal Band Saw Blade RÖNTGEN Grit – Continuous-Coating Cutting Blade for Precise Chip-Free Cutting

RÖNTGEN Grit Continuous-Coating Metal Saw Blade is a specialist bimetal band designed for precise cutting of chip-free materials. The carbide grit coating allows efficient cutting of a wide range of hard-to-machine materials such as technical ceramics, graphite, composites, carbon fibres, and plastics. The high manufacturing quality and fatigue resistance of the backing make the HM Grit an ideal solution for workshops requiring reliability, process stability, and superior cut surface quality.

Main Advantages of the RÖNTGEN Grit Bimetal Blade

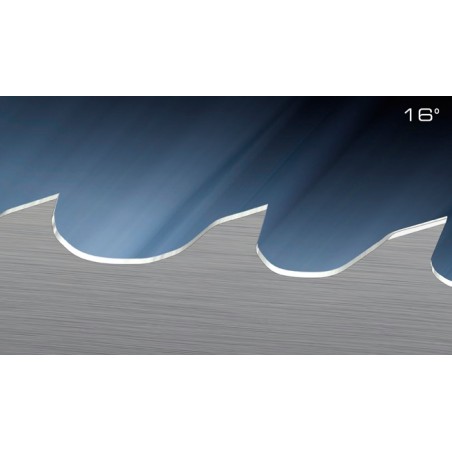

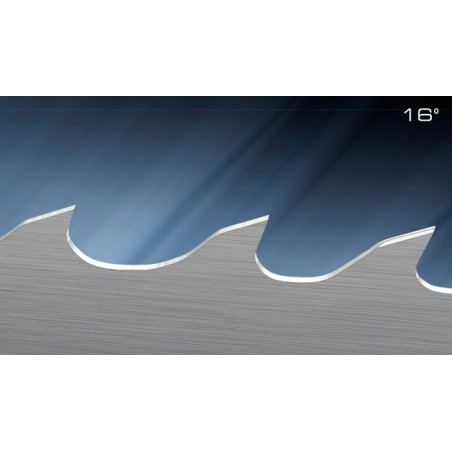

- Continuous carbide-coated cutting edge – enables abrasive cutting of chip-free materials.

- Bidirectional operation – the blade cuts both forward and backward, increasing flexibility of use.

- No cutting teeth – cutting is performed solely through abrasion, eliminating the risk of tooth breakage.

- Sharp abrasive surface – ensures precision and clean edges even for brittle materials.

- Fatigue resistance – the backing strip made of hardened alloy steel ensures long service life.

Construction and Technology

The RÖNTGEN Grit band saw blade is designed for high band speed operation to maximise the abrasive effect. Its structure is based on a durable bimetal backing made of hardened steel, ensuring rigidity and stability. The working surface is coated with carbide grit of various grain sizes, selected according to material type and surface finish requirements. The continuous coating eliminates cutting gaps, ensuring uniform load and a consistent surface finish. Welds are produced using technology that guarantees strength and compatibility with industrial saws.

Precision and Performance

The abrasive cutting technology ensures a stable and repeatable process, even when machining materials with low thermal conductivity or high brittleness. The Grit cutting blade delivers excellent edge quality, reducing the need for additional finishing operations. Thanks to bidirectional operation and a wide grit range, users can optimise parameters for cutting speed and cost efficiency. It is an ideal solution for industries such as aerospace, automotive, plastics and composite processing, and mould manufacturing.

Applications

RÖNTGEN Grit cutting blade is suitable for cutting:

- Composite materials (e.g. CFRP, GFRP),

- Technical ceramics,

- Graphite, carbon fibres, porous materials,

- Plastics and rubber,

- Non-ferrous metals and thin-walled superalloys.

Standard Equipment

- Carbide grit coating in various grades (e.g. Grit 60, 80, 120),

- Backing strip resistant to tension and fatigue cycles,

- Compatibility with manual, semi-automatic, and automatic band saws,

- High working speed – up to 1,500 m/min depending on material.

Optional Equipment

- Various band widths (6–67 mm),

- Lengths compatible with CORMAK and other saw brands,

- Custom grit selection for specific production processes.

Technical Data

| Parameter | Value |

|---|

| Band type |

Bimetal with carbide coating |

| Cutting type |

Abrasive, chip-free |

| Operation |

Bidirectional (continuous) |

| Band width |

6 – 67 mm |

| Band thickness |

0.6 – 1.6 mm |

| Grit size |

60 – 120 (depending on application) |

| Band material |

Bimetal steel + carbide coating |

| Working speed |

up to 1,500 m/min |

Precision Cutting of Hard Materials? Choose Grit

If you are looking for a metal and non-metal cutting saw blade of the highest precision, the RÖNTGEN Grit continuous-coating cutting blade is a professional tool for your production. Thanks to abrasive cutting in both directions and a wide grit range, the Grit band provides the flexibility and quality required by modern industrial processes.

Order now and raise your cutting processes to the next level!

Write your review

* Required fields

I accept privacy policy rules