Bimetal Bandsaw Blade RÖNTGEN bi-alfa cobalt M42 – professional cutting blade for metal

The Bimetal Bandsaw Blade RÖNTGEN bi-alfa cobalt M42 is a precision cutting blade of industrial grade, designed for efficient cutting of metals with different hardness levels. Using cobalt HSS-M42 teeth and advanced heat treatment, the blade demonstrates exceptional wear resistance and extended durability, even during long production cycles.

Main advantages of the RÖNTGEN bi-alfa cobalt M42 metal bandsaw blade

- Professional HSS-M42 teeth – exceptional durability due to 8% cobalt content and martensitic structure.

- High temperature resistance – teeth maintain hardness at elevated temperatures, reducing wear at high cutting speeds.

- Flexible alloy backing with chromium addition – enhanced resistance to cracking and operational stress.

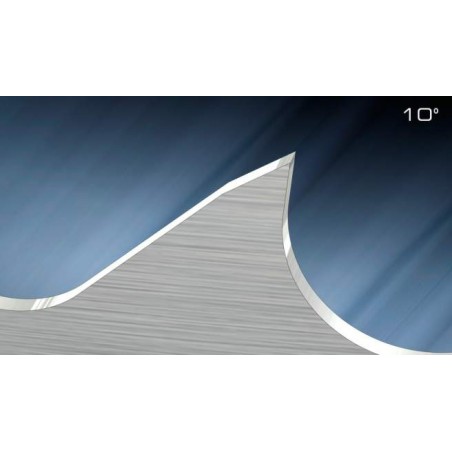

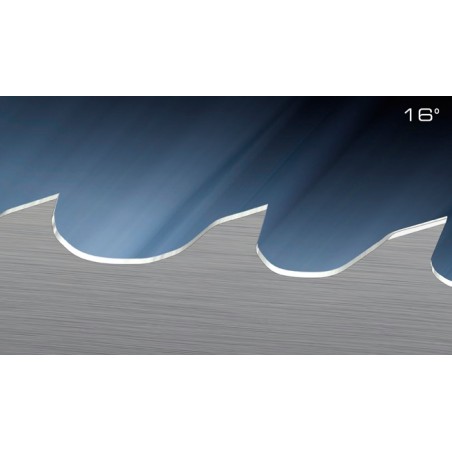

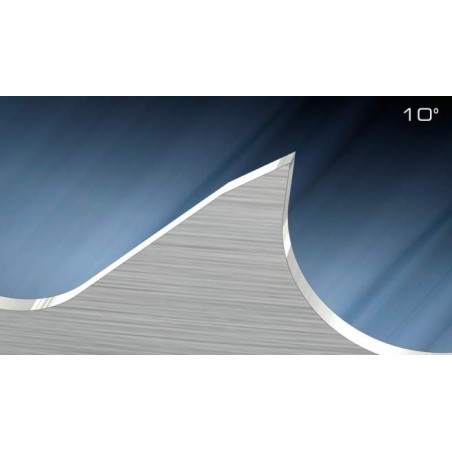

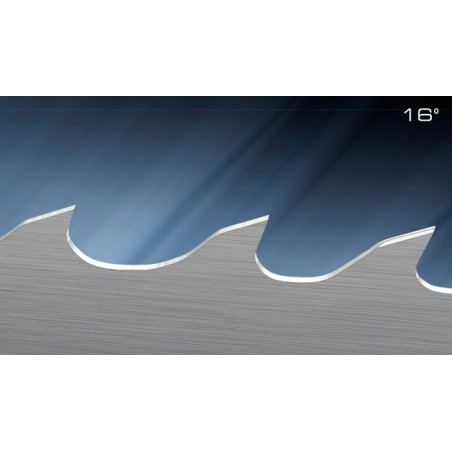

- Fast and precise cutting – optimised rake angle and tooth geometry enable effective cutting of both solid and profiled materials.

- Suitable for continuous operation – perfect for modern CNC and semi-automatic bandsaws.

Construction and manufacturing technology

The RÖNTGEN bi-alfa cobalt M42 cutting blade is manufactured using the latest metallurgical and heat-treatment technologies. The HSS-M42 teeth are hardened and tempered, ensuring uniform carbide distribution and superior abrasion resistance. The chromium-alloy backing increases flexibility and fatigue resistance, making the blade ideal for industrial environments where precision and reliability are crucial.

Precision and performance

The blade’s tooth geometry is optimised for high cutting efficiency and reduced cutting forces. This ensures fast cutting of materials such as structural steel, stainless steel, tool steel, non-ferrous metals, and aluminium. The high thermal stability of the teeth extends tool life significantly, reducing downtime and replacement frequency.

Applications

The RÖNTGEN bi-alfa cobalt M42 bandsaw blade is suitable for:

- Metal fabrication plants processing steel and non-ferrous materials,

- Steel distribution centres and cutting facilities,

- Toolmaking and metalworking workshops,

- Construction and industrial sectors – for cutting profiles, sections, and solid materials.

Standard equipment

- Bimetal HSS-M42 cutting blade with a carefully selected tooth pitch.

- Chromium-alloy backing resistant to material fatigue.

- Ready for installation in most CORMAK bandsaws and compatible machines from other manufacturers.

Optional equipment

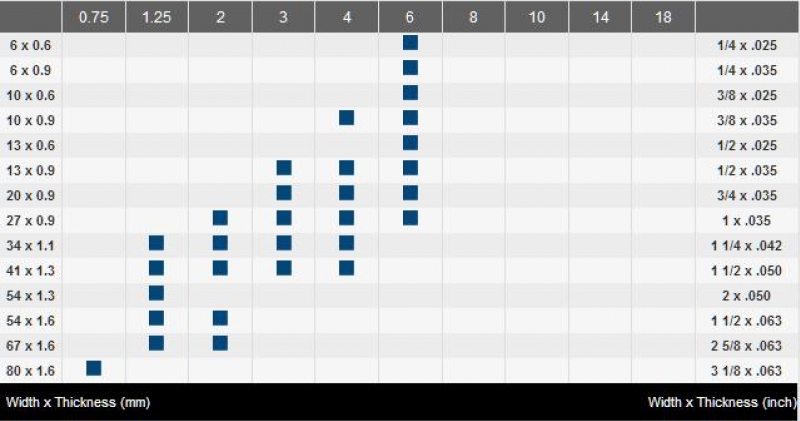

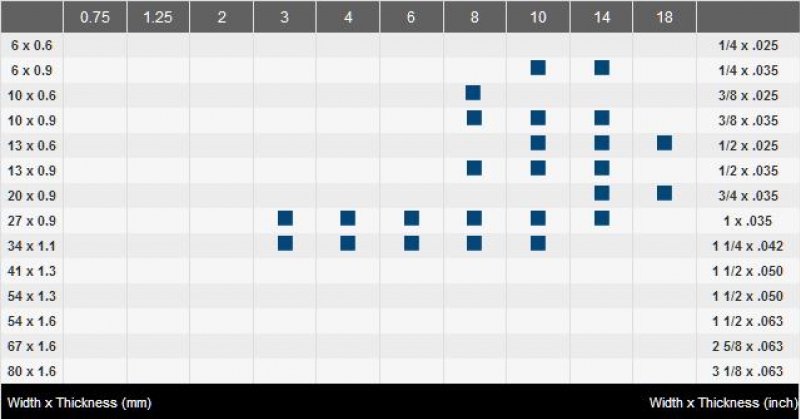

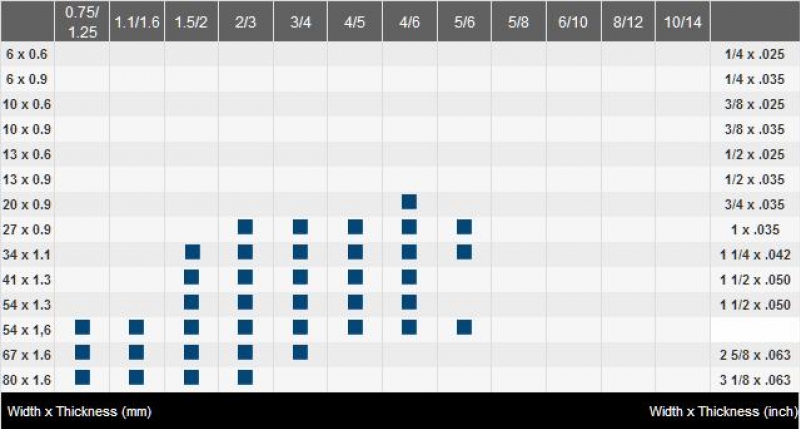

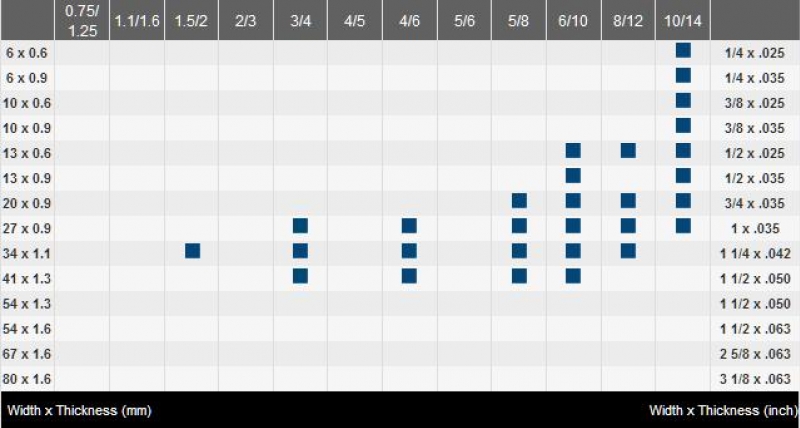

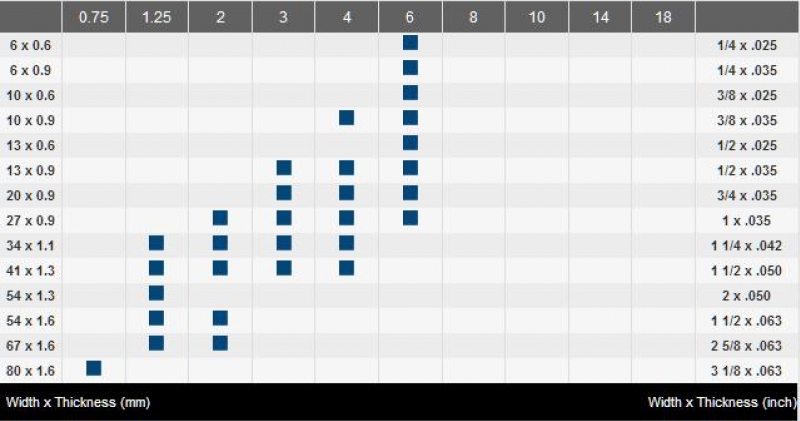

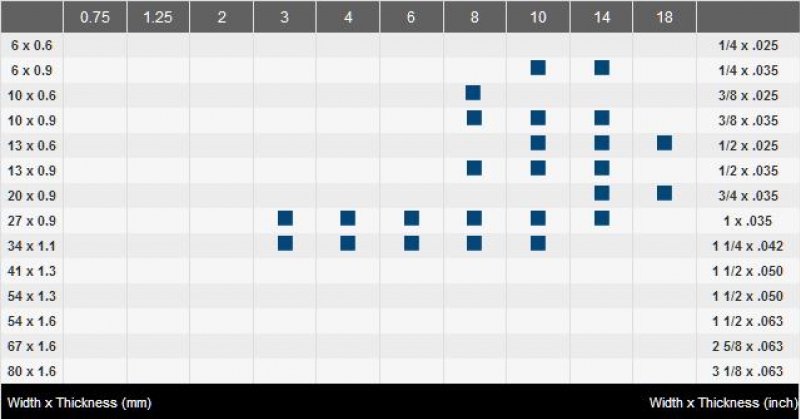

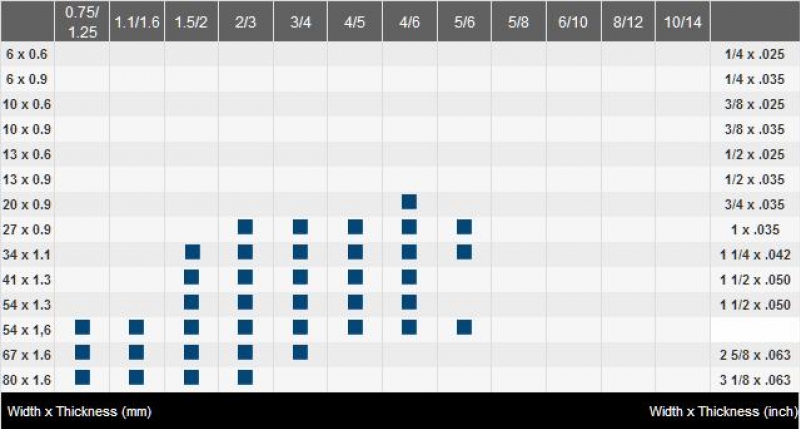

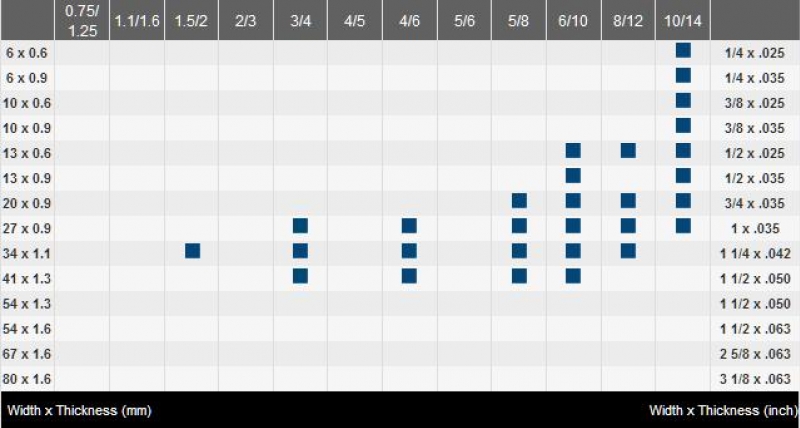

- Various tooth pitches (e.g. 4/6 TPI, 3/4 TPI, 2/3 TPI) depending on material type.

- Custom blade lengths adapted to specific bandsaw models.

- Special configurations for cutting stainless steel, duplex, Inconel, and titanium.

Technical data

| Blade type | Bimetal HSS-M42 |

|---|

| Blade width |

6–41 mm (depending on model) |

| Blade thickness |

0.65–1.3 mm |

| Tooth material |

HSS M42 (8% Co) |

| Backing material |

Chromium alloy steel |

| Application |

Structural steel, stainless steel, non-ferrous metals |

| Tooth geometry |

Constant or variable pitch (2/3 – 10/14 TPI) |

Choose proven metal-cutting performance

If you are looking for a reliable and durable metal-cutting bandsaw blade for demanding industrial use, the RÖNTGEN bi-alfa cobalt M42 is the perfect choice. Its superior quality, wear resistance, and cutting efficiency make it the preferred solution for professionals.

Order now and increase your metal-cutting productivity with RÖNTGEN precision technology.

Teeth per inch

HOOK TOOTH (full-height)

Full-height tooth

HOOK TOOTH

Full-height tooth

2022-04-15

usprawnienie komunikacji

Czy ceny pił taśmowych są zaklętą, Waszą tylko tajemnicą. Aby się o niej dowiedzieć trzeba tracić czas swój i absorbować konsultantów. Prosta komunikacją zachęca do zawarcia kontaktu kupna.

Pozdrawiam.