- Reduced price

The basket is empty.

Compact device using FIBER technology designed for welding various types of metals with precision far exceeding that of traditional welding methods.

Advanced technological solutions used in this welder allow for the creation of high-quality, repeatable welds on thin-walled materials and components without the risk of deformation.

CORMAK LASER WELDERS COME WITH A 24-MONTH WARRANTY!

| Maximum power | 1000 W |

| Laser wavelength | 1080 nm |

| Penetration depth (stainless steel 1 m/min) | 2.68 mm |

| Penetration depth (mild steel 1 m/min) | 2.06 mm |

| Penetration depth (aluminium 1 m/min) | 2.0 mm |

| Penetration depth (brass 1 m/min) | 2.0 mm |

| Welding speed | 0–120 mm/s |

| Automatic wire feeder | Ø 0.8–1.2 mm |

| Maximum power consumption | ≤3 kW |

| Cooling system | Water-cooled |

| Operating voltage | 230V |

| Shielding gas consumption | approx. 10–12 L/mm Ø wire |

| Dimensions | 600 × 1100 × 1100 mm |

| Weight approx. | 120 kg |

THICKNESS OF WELDED MATERIALS |

||||

| Material |

WELDER POWER |

|||

| 1000 W | 1500 W | 2000 W | 3000 W | |

| Stainless steel | 0.5–3.0 mm | 0.5–4.0 mm | 0.5–5.0 mm | 0.5–8.0 mm |

| Mild steel | 0.5–2.5 mm | 0.5–3.5 mm | 0.5–4.5 mm | 0.5–8.0 mm |

| Galvanised steel | 0.5–1.2 mm | 1.5–1.8 mm | 1.5–4.0 mm | 1.5–7.0 mm |

| Aluminium | 0.5–1.2 mm | 1.5–1.8 mm | 1.5–4.0 mm | 1.5–7.0 mm |

| Brass | 0.5–1.2 mm | 1.5–1.8 mm | 1.5–2.5 mm | 1.5–4.0 mm |

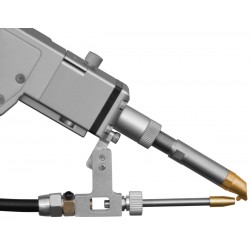

LATEST GENERATION WELDING HEAD

Automatic wire feeder included

The wire feeding system is synchronised with the welder’s software. Its purpose is to feed filler material, allowing the operator to fully focus on working with the head.

Choosing the right welding mode allows achieving optimal results. The mode should be selected depending on the type and thickness of the welded material.

*Infinity symbol mode – EXCLUSIVE TO US, AVAILABLE AS AN ADDITIONAL OPTION

Mode dedicated to hard-to-weld materials with preheating. Produces a flat seam that requires no further processing — particularly useful when welding very thin materials.

The appearance of the housing may vary depending on the order date, but the technical specification remains unchanged, ensuring consistent quality and performance.

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Welding Positioner CORMAK PS-180

The CORMAK PS-180 welding positioner is a versatile auxiliary device designed for various production tasks. Its wide range of capabilities makes it ideal wherever component manipulation is required. The welding, painting and mechanical industries appreciate the quality and functionality of CORMAK ...More

Welding Positioner CORMAK PS-310

The CORMAK PS-310 welding positioner is a versatile auxiliary device used in various production processes. Its wide range of functions makes it ideal wherever component rotation and positioning are required. Appreciated by the welding, painting and mechanical industries, CORMAK positioners combine ...More

Welding Positioner CORMAK PS-320

The CORMAK PS-320 welding positioner is a compact and efficient device designed for precise clamping and rotation of welded components. It is ideal for workshops and production facilities that require accuracy, repeatability and ergonomic operation. Combined with the WP300 self-centring chuck, it ...More

Welding Positioner CORMAK PS-360

The CORMAK PS-360 welding positioner is a versatile auxiliary device designed for professional welding and assembly operations. With a wide range of capabilities, it performs perfectly wherever precise rotation and positioning of components are required. The welding, painting and mechanical ...More

Welding Positioner CORMAK PS-500

The CORMAK PS-500 welding positioner is a robust and versatile auxiliary device designed for a wide range of production and assembly tasks. It allows efficient manipulation of workpieces, making it an essential tool for welding, painting and mechanical workshops. Its durable construction, ...More

Welding Positioner CORMAK PS-650

The CORMAK PS-650 welding positioner is a versatile auxiliary device used in a wide range of production tasks. Its broad capabilities make it ideal wherever workpieces need to be rotated or positioned. The welding, painting, and mechanical industries have recognized the quality and rotational ...More

Mobile Welding and Assembly Workbench CORMAK ST915 540kg

The compact and robust structure of the table allows for very wide application, from welding and locksmithing to grinding and other finishing operations. Thanks to the lower shelf for handy tools and accessories, it becomes an essential workstation in every workshop. THE TABLETOP IS 4 mm THICK ...More

Dual Automatic Wire Feeder CORMAK for Laser Welding Machines

The dual wire feeder has been designed to enhance the efficiency and quality of welding processes in the most demanding industrial environments. Thanks to its innovative construction allowing the use of two different welding wires, this feeder is an ideal solution for CORMAK laser welding machines, offering users a range of benefits. ...More

Laser Welding Machine CORMAK WL1500 3in1 – Special Offer

We present the latest industrial laser welding machine CORMAK WL1500, combining advanced FIBER technology with innovative design solutions to offer unmatched precision and performance. Designed for welding various types of metals, it ensures top-quality, repeatable welds. With its 3in1 function for ...More

Laser Welding Machine CORMAK SL1500 3in1 – Welding, Cleaning and Cutting

Modern FIBER-based device designed for welding various types of metals, offering precision far superior to traditional methods. The 3in1 function enables laser welding, cutting and cleaning, making it versatile and efficient across many industrial applications. Advanced technological solutions ...More

Welding Positioner CORMAK PS-360

The CORMAK PS-360 welding positioner is a versatile auxiliary device designed for professional welding and assembly operations. With a wide range of capabilities, it performs perfectly wherever precise rotation and positioning of components are required. The welding, painting and mechanical ...More

Laser Welding Machine CORMAK SL1000 3in1 – Welding, Cleaning and Cutting

Modern FIBER-based device designed for welding various types of metals, offering precision far superior to traditional methods. The 3in1 function enables laser welding, cleaning and cutting, making it versatile and efficient across many industrial applications. Advanced technology ensures ...More

Laser Welding Machine CORMAK SL2000 3in1 – Welding, Cleaning and Cutting

Modern FIBER-based device designed for welding various types of metals, offering precision far exceeding traditional methods. The 3in1 function enables laser welding, cutting and cleaning, making it versatile and efficient across many industrial fields. Advanced technological solutions allow for ...More

Laser Welding Machine CORMAK SL3000 3in1 – Welding, Cleaning and Cutting

Modern FIBER-based device designed for welding various types of metals, offering precision far exceeding traditional methods. The 3in1 function enables laser welding, cutting and cleaning, making it versatile and efficient across many industrial fields. Advanced technological solutions allow for ...More

Mobile Welding and Assembly Workbench CORMAK ST915 540kg

The compact and robust structure of the table allows for very wide application, from welding and locksmithing to grinding and other finishing operations. Thanks to the lower shelf for handy tools and accessories, it becomes an essential workstation in every workshop. THE TABLETOP IS 4 mm THICK ...More

Laser Welding Machine CORMAK WL1500

Compact device using FIBER technology designed for welding various types of metals with precision far exceeding traditional welding methods. Advanced technological solutions used in this welder enable high-quality, repeatable welds on thin-walled materials and components without risk of ...More

Laser Welding Machine CORMAK WL3000

Compact device using FIBER technology designed for welding various types of metals with precision far exceeding traditional welding methods. Advanced technological solutions used in this welder ensure high-quality, repeatable welds on thin-walled materials and components without the risk of deformation. ...More

LaserProtect PREMIUM Personal Protective Equipment Set for Laser Welding

Top-class personal protective equipment set for working with laser welding systems, laser cleaning, and environments with increased dust and fume concentration. Includes protective apron, 3K gloves, PROTECT helmet with air supply, and TERMINATOR 0275 laser safety glasses. Maximum safety, comfort, and ergonomics. ...More

Welding Positioner CORMAK PS-500

The CORMAK PS-500 welding positioner is a robust and versatile auxiliary device designed for a wide range of production and assembly tasks. It allows efficient manipulation of workpieces, making it an essential tool for welding, painting and mechanical workshops. Its durable construction, ...More

Laser Welding Machine CORMAK WL2000 3in1 – Special Offer

We present the latest industrial laser welding machine CORMAK WL2000, which combines advanced FIBER technology with innovative design solutions, offering unmatched precision and performance. Designed for welding various types of metals, it ensures top-quality and repeatable welds. Thanks to its ...More

Laser Welding PPE Set CORMAK LaserProtect EXPERT

Extended personal protective equipment set for working with laser welding systems. The set includes: protective apron, 3K gloves, laserPRO helmet and TERMINATOR 0275 laser safety glasses. An ideal solution for users seeking a balance between price and an increased level of eye protection. ...More

Fibre Laser Welder CORMAK A200

The A200 laser welder is a modern device designed for precision welding tasks. The use of fibre technology ensures high electro-optical conversion efficiency, exceptional beam quality, and a compact structure. With 2000W of power, the A200 is ideal for fast and efficient welding of thin ...More

Write your review

* Required fields

I accept privacy policy rules