Laser Welding Machine CORMAK SL2000 3in1 – performance and precision for professionals

CORMAK SL2000 Laser Welding Machine is an advanced industrial FIBER system providing comprehensive welding, cutting and laser cleaning functions in one unit. With a 2000 W laser source and a modern design, this machine is ideal for facilities where welding speed, joint quality and reliability are key factors.

As part of a special offer, the machine comes with a complete set of U-groove rollers, a Teflon wire feeding tube and a cleaning kit (lens and nozzle)

Main Advantages

- High laser power – 2000 W – enables deep penetration and welding of thicker materials without multiple passes.

- Welding speed up to 120 mm/s – significantly reduces production time compared to conventional methods.

- Concentrated laser beam – minimal heat-affected zone ensuring clean, durable weld seams.

- Thin material capability – allows welding of stainless steel from 0.5 mm thickness.

- Option to weld with or without wire – flexibility to match process requirements.

- Laser cleaning and cutting modes – extend the machine’s versatility and daily usability.

- Automatic wire feeder – fully synchronised with the control software for process stability.

Design and Technology

CORMAK SL2000 is equipped with a 1080 nm fiber laser source and an advanced head with adjustable spot size (0–5 mm), enabling welds even in hard-to-reach areas. The water-cooling system and 230 V operating voltage ensure safe and stable performance across various production environments. Interchangeable nozzles and ergonomic design make servicing and daily operation simple and efficient.

Precision and Efficiency

The penetration depth for stainless steel at 1 m/min reaches 4.57 mm, which is an excellent result for a compact industrial unit. Adjustable welding parameters allow full control over seam quality — for both thin elements and thicker construction components. Stable beam parameters guarantee repeatability and a clean aesthetic finish.

Applications

- Metalworking plants and industrial workshops

- Production of railings, light structures and steel frames

- Automotive, household appliance and electronics industries

- Laser cutting and cleaning of metal components

Standard Equipment

- Laser welder with integrated cooling system

- Welding gun with adjustable focal length

- Fiber laser source

- Automatic wire feeder Ø 0.8–1.6 mm

- Complete cable set

- Starter kit of nozzles and protective lenses

Optional Equipment (option*)

- Optical kit for laser cleaning – 333,00 € net – FREE under the special offer

Technical Data

| Maximum power |

2000 W |

| Laser wavelength |

1080 nm |

| Penetration depth (stainless steel 1 m/min) |

4.57 mm |

| Penetration depth (carbon steel 1 m/min) |

3.59 mm |

| Penetration depth (aluminium 1 m/min) |

4.0 mm |

| Penetration depth (brass 1 m/min) |

4.0 mm |

| Welding speed |

0–120 mm/s |

| Automatic wire feeder |

Ø 0.8–1.6 mm |

| Maximum power consumption |

≤6.0 kW |

| Cooling system |

Water-cooled |

| Operating voltage |

230 V |

| Shielding gas consumption |

approx. 10–12 L/mm Ø wire |

| Dimensions |

600 × 1100 × 1100 mm |

| Weight approx. |

185 kg |

Weldable Material Thickness

| WELDABLE MATERIAL THICKNESS |

| Material |

WELDER POWER |

| 1000 W |

1500 W |

2000 W |

3000 W |

| Stainless steel |

0.5–3.0 mm |

0.5–4.0 mm |

0.5–5.0 mm |

0.5–8.0 mm |

| Carbon steel |

0.5–2.5 mm |

0.5–3.5 mm |

0.5–4.5 mm |

0.5–8.0 mm |

| Galvanised steel |

0.5–1.2 mm |

1.5–1.8 mm |

1.5–4.0 mm |

1.5–7.0 mm |

| Aluminium |

0.5–1.2 mm |

1.5–1.8 mm |

1.5–4.0 mm |

1.5–7.0 mm |

| Brass |

0.5–1.2 mm |

1.5–1.8 mm |

1.5–2.5 mm |

1.5–4.0 mm |

Additional Information

Video tutorials: CORMAK provides instructional videos on YouTube showing machine setup and operation. Recommended before use.

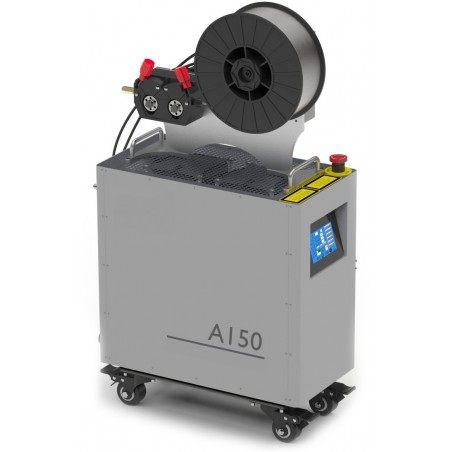

Note: The housing design may vary depending on production batch. Model codes SL and WL are interchangeable and have no effect on performance or parameters.

Order the CORMAK SL2000 Laser Welding Machine today and take advantage of advanced FIBER laser technology in your workshop. Invest in reliability and increase your production efficiency now.

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.

Write your review

* Required fields

I accept privacy policy rules