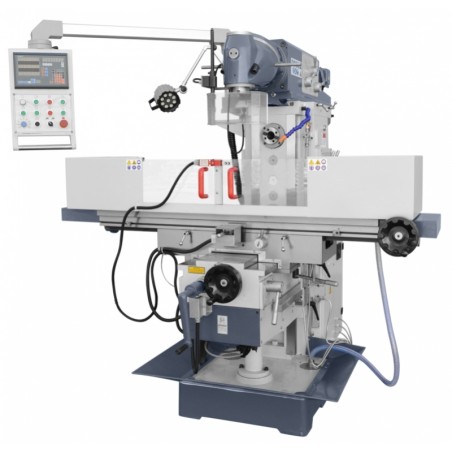

Discover a new era of conventional milling with the CORMAK UWF 110 SERVO Universal Milling Machine. Thanks to innovative servo drive technology for axis movement, this model achieves exceptional machining precision and superior surface finish quality. The use of modern components enhances both process stability and overall machine performance, while the ergonomic design ensures intuitive operation. The UWF 110 SERVO is a perfect choice for professionals who value accuracy, reliability, and efficiency in everyday machining operations.

Technical Parameters

|

Table dimensions

|

1270 (option 1370) x 300 mm

|

|

Max longitudinal travel (X)

|

720 (option 1000) mm

|

|

Max cross travel (Y)

|

380 mm

|

|

Max vertical travel (Z)

|

400 mm

|

|

Number of T-slots

|

3

|

|

T-slot width

|

14 mm

|

|

Spindle taper

|

ISO40

|

|

Distance spindle – table surface

|

80–660 mm

|

|

Rapid feed (X-axis)

|

1000 mm/min

|

|

Rapid feed (Y-axis)

|

1000 mm/min

|

|

Rapid feed (Z-axis)

|

750 mm/min

|

|

Main motor power

|

3 kW

|

|

Coolant pump power

|

60 W

|

|

Net weight

|

1350 kg

|

|

Overall dimensions

|

1720 x 1680 x 1700 mm

|

Included Equipment

- Digital readout system for 3 axes

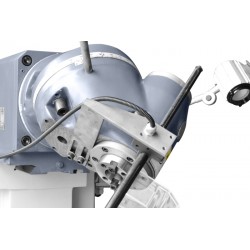

- Horizontal spindle support arm

- Two long milling arbors

- Worktable guard

- Milling arbor with collet chuck set for end mills

- Drill chuck 1–16 mm

- ISO40 / Morse taper reduction sleeves

- 24V lighting system

- Coolant system

Optional Equipment

- Rotary vices

- Swivel vices

- Precision vices

- Indexing tables

- Dividing heads

- Threading heads

- Milling heads

- Milling cutters (HSS, HSSE, HSS-PM, VHM)

- Cylindrical drills

- Conical drills

- Milling inserts

- Manual and machine tap and dies

- Set of mounting elements

- Tool holders (for collets, Weldon)

- Shell end mill arbors

- Drilling chucks

Write your review

* Required fields

I accept privacy policy rules