The presented configuration represents the most frequently chosen equipment by customers – a proven and efficient choice for serial production.

Main Features:

-

Front supports: 2 pieces on linear guides, ensuring stability during bending operations

-

Axis Y1, Y2 adjustment: automatic

-

Backgauge adjustment (axis X): servomotor with encoders

-

Axis R adjustment: servomotor with encoders

-

Automatic deflection compensation

-

Double-sided punch clamping: quick AMADA-type system for fast tool changes

-

Motor: 7.5kW (option*)

Available configurations are tailored to production needs and the type of processed components – the machine specification is determined individually according to application and technological requirements.

Technical Specifications

| Max. sheet thickness (S235) |

up to 6.0 mm |

| Nominal pressure |

1,250 kN |

| Max. bending length |

2,500 mm |

| Throat depth |

400 mm (option* 550 mm or 620 mm) |

| Max. stroke of moving beam |

200 mm (option* 300 mm or 400 mm) |

| Max. open height |

390 mm |

| Distance between frames |

2,000 mm |

| Backgauge travel |

650 mm (option* 1,000 mm) |

| Motor power |

7.5 kW |

| Length |

2,650 mm |

| Width |

1,550 mm |

| Height |

2,400 mm |

| Weight |

6,200 kg |

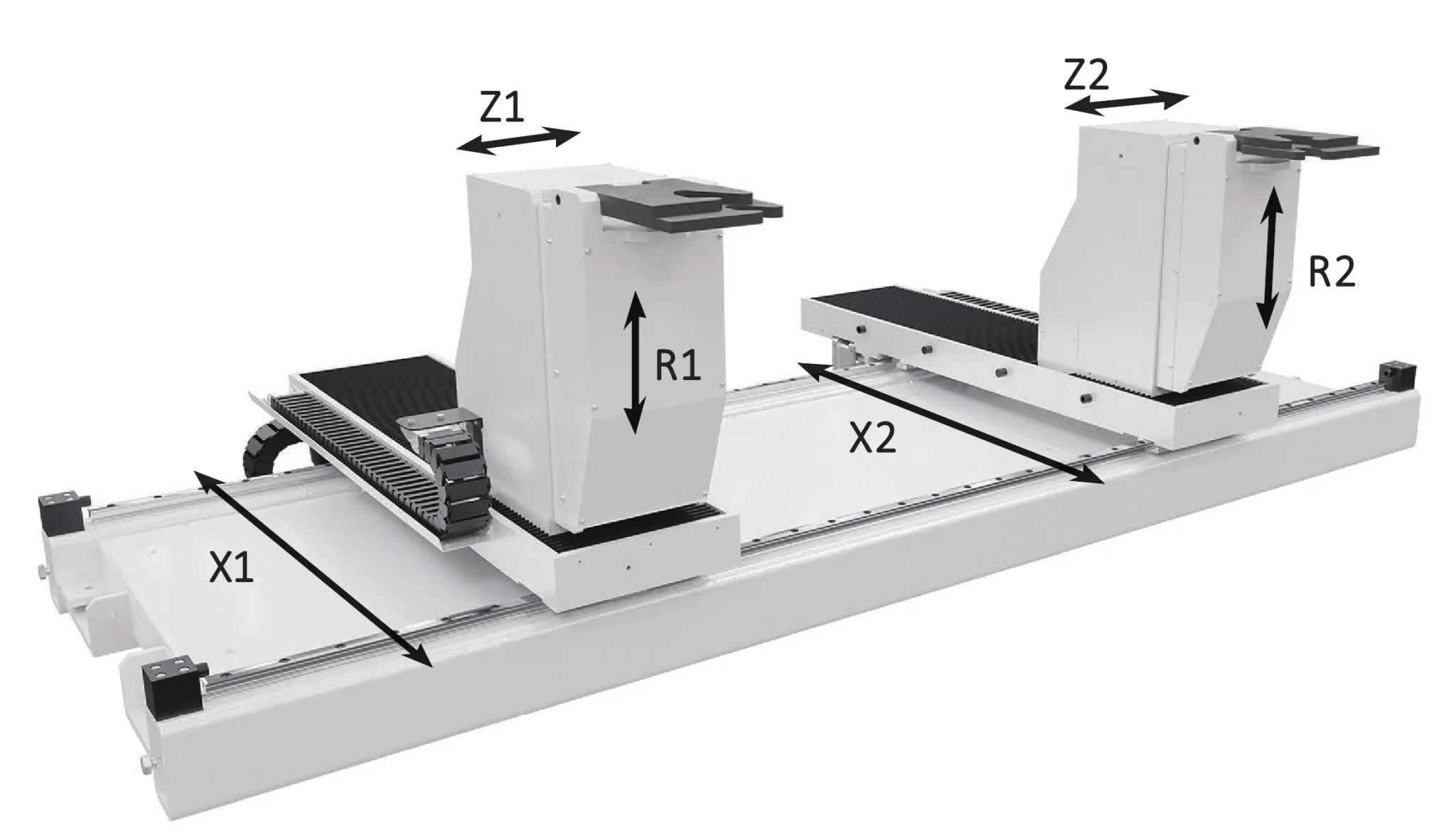

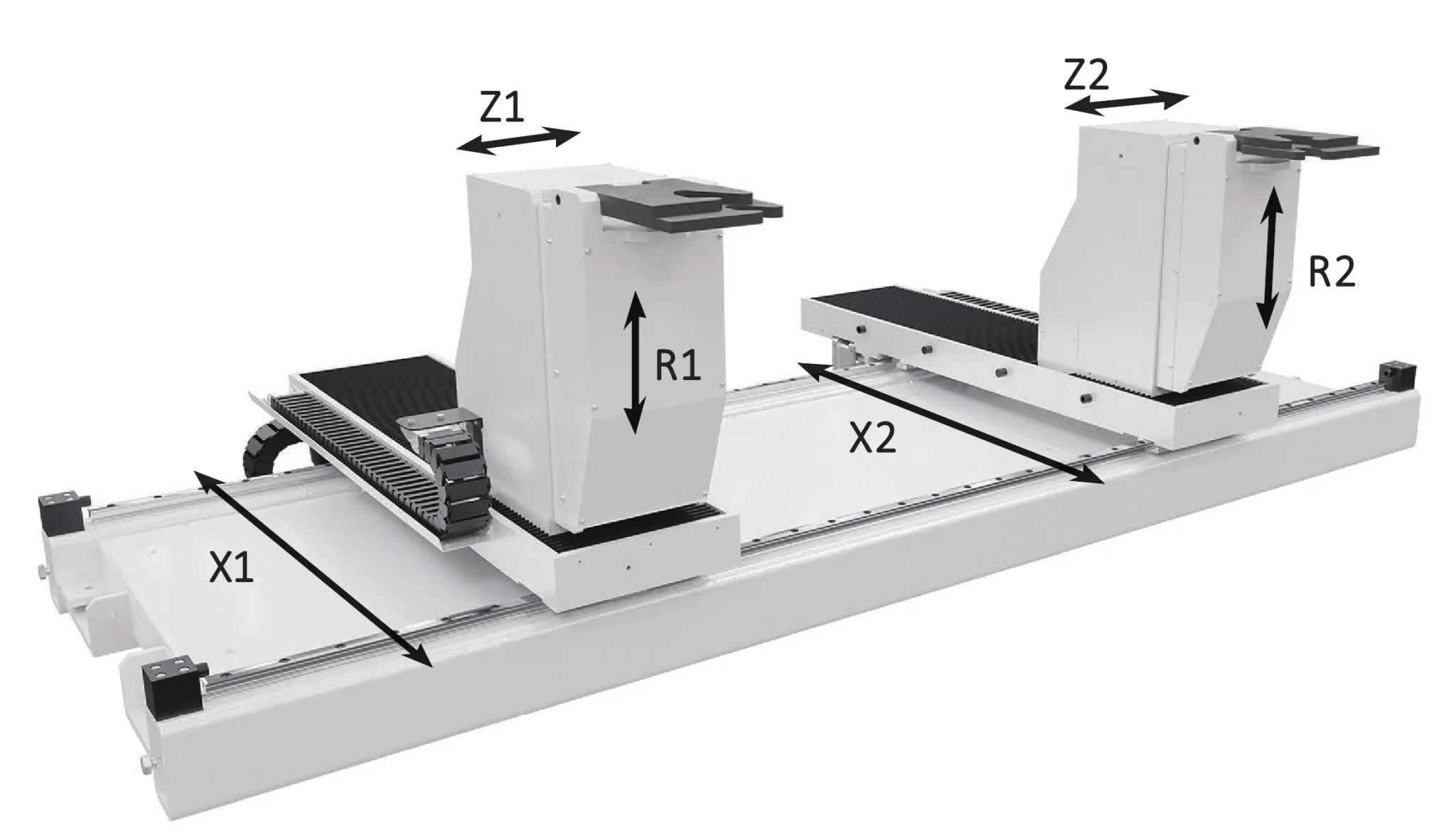

Automatic adjustment of backgauge travel (axis X) and axis R (optionally manual). Axis R facilitates bending of larger radii, e.g. with step bending system.

Optionally, finger adjustment in axes Z1, Z2, R1, R2, X1, X2 on servomotors.

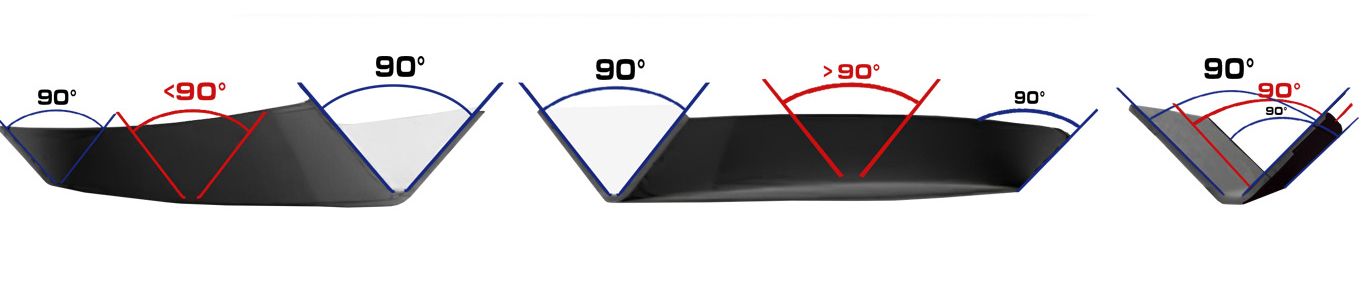

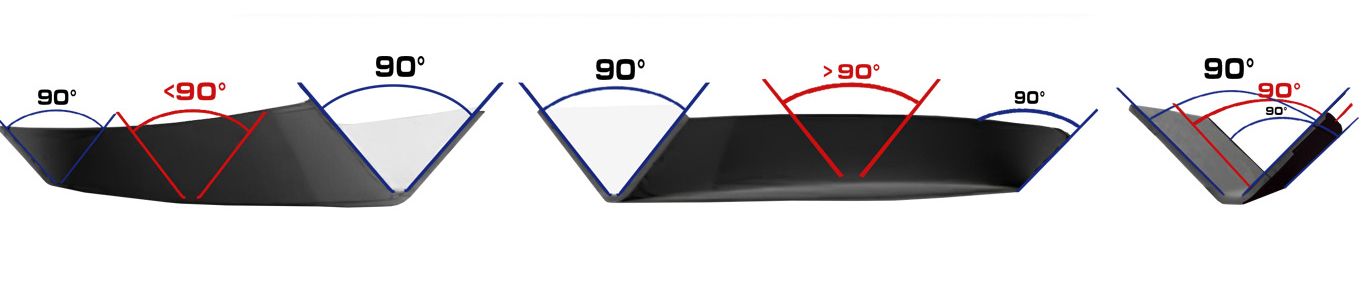

For the step bending process to deliver satisfactory results, it is necessary to perform certain calculations requiring knowledge of key parameters related to bending:

- Arc length – the distance between the ends of the curved sheet section measured along the inner side of the bend;

- Number of bends – the number of single bends required to obtain a sheet with a specific radius; the more bends, the smaller the individual bending angle and the smoother the arc;

- Distance between bends – the spacing between successive bends made during the process.

Although the entire step bending process may seem quite complex, the CORMAK machines and software are already so advanced that they handle most of the operations automatically, relieving the operator from manual calculations.

Automatic deflection compensation

Ensures a uniform bending angle along the entire length of the bend – (option*)

Manual deflection compensation (option*)

Ensures a uniform bending angle along the entire bending length – (option*)

High-quality components:

- Electrical system components by Schneider / Delta / Eaton

Control and Functionality:

DELEM DA-53TX

- Equipped with a 15” touchscreen mounted on a movable arm, allowing convenient operation across the machine’s entire workspace

- Advanced programming algorithms with automatic bending sequence calculation

- Control of up to four axes, enabling more complex operations

- Compatible with multiple press brake configurations

- Option*: drawing of the bent element directly on the controller screen /2D/

- Option*: bending program generation based on an imported product drawing /2D/

- Option*: real-time 2D visualisation of bending sequence

Also available (option*) DELEM controllers DA-53T+2D, DA-66T as well as DA-69T and CYBELEC 12

DA-53T+2D

Display

- 10.1" TFT LCD touchscreen

- colour display

External software

- Offline workstation licence Profile-53TL (for creating bending sequences on PC)

System

- Windows operating system

- 200 MHz processor

- 1GB internal memory

- Collision-prevention logic for all working axes

Functions

- Punch and die library /30 punches & 60 dies/ – descriptive and graphical

- Program library with graphical preview and product cataloguing

- Material database (ability to add new material types)

- Drawing of bent elements directly on the screen /2D/

- Bending program generation from imported drawing /2D/

- 2D simulation of bending sequence in real time

- Step-by-step 2D simulation with collision preview

- Warning system (e.g., exceeding tool strength)

- Option to change bending sequence and modify steps

- Manual mode operation

- Manual axis positioning via backgauge control

- Automatic stroke calculation

- Automatic bending force and position calculations

- Automatic radius and material allowance calculations

- Backup creation for products and tools

- USB port

DA-58T

Display

- 15" TFT LCD touchscreen

- colour display

External software

- Offline workstation licence Profile-53TL (for PC bending sequence creation)

System

- Windows operating system

- 200 MHz processor

- 4Mb RAM

- Max. number of programs: 9,999 (25 steps max)

- Max. repeat per step: 99

- Collision-prevention control logic for all axes

Functions

- Punch and die library /30 punches & 60 dies/

- Graphical and descriptive libraries

- Program library with graphic preview and product catalogue

- Material database (option to add new materials)

- Drawing and programming /2D/ directly on the controller screen

- 2D real-time bending simulation and sequence visualisation

- 2D collision simulation /step-by-step/

- Warning notifications (e.g. exceeding tool strength)

- Change of sequence order and correction of program steps

- Manual operation and positioning of individual axes

- Automatic stroke calculation

- Automatic bending force and backgauge positioning

- Automatic internal radius and material expansion calculation

- Product and tool backup capability

- USB port

DA-66T

Display

- 17” TFT LCD touchscreen

- colour display

External software

- LITE T2D licence (for offline bending sequence creation on PC)

System

- Intuitive control with graphical interface

- Stable Windows CE operating system

- 64Mb RAM

- Max. programs: 1,000 /1GB/

- Max. repetitions: 99

Functions

- Drawing of bent elements directly on the screen /2D/

- Automatic bending program generation /2D/

- Automatic stroke and bending force calculations

- Automatic backgauge setting according to program

- 3D bending simulation /step-by-step visualisation/

- Automatic positioning of fingers behind chosen punch/die segments

- Collision and overload warnings

- Automatic sheet development calculation

- Correction and sequence editing options

- Manual mode with navigation wheel

- Material, punch and die libraries

- Program counter and working hours meter

- USB port

- Backup functionality for products and tools

DA-69T

Display

- 17” TFT LCD touchscreen

- colour display

External software

- LITE T3D licence (for 3D bending sequence creation on PC)

System

- Intuitive control interface

- Stable Windows CE operating system

- 64Mb RAM

- Max. programs: 1,000 /1GB/

- Max. repetitions: 99

Functions

- DXF file import

- 3D IGES & SAT import from LITE T3D software

- 3D drawing of bent elements directly on the screen

- Automatic bending program generation from 3D drawing

- Automatic stroke and bending force calculations

- Automatic backgauge positioning

- 3D bending simulation (step-by-step visualisation)

CYBELEC 12

Display

- 12” TFT LCD touchscreen

- colour display

System

- Intuitive control with graphical interface

- Stable Windows CE operating system

- Max. punches: 100

- Max. programs: 300

- Max. step repetitions: 24

- Max. materials: 10

Functions

- User-friendly HMI interface

- 2D profile drawing and 3D visualisation

- Automatic bending sequence generation

- High bending precision with advanced algorithms

- Tandem operation

- Tool import

- Pre-bending and final bending

- Angle measurement support

- Barcode reader support

- Industry 4.0 configurable

The machine combines advanced technology with user-friendly operation, making it ideal for both precise manual tasks and efficient serial production. High-quality components and advanced safety systems ensure reliability and operator safety.

Safety

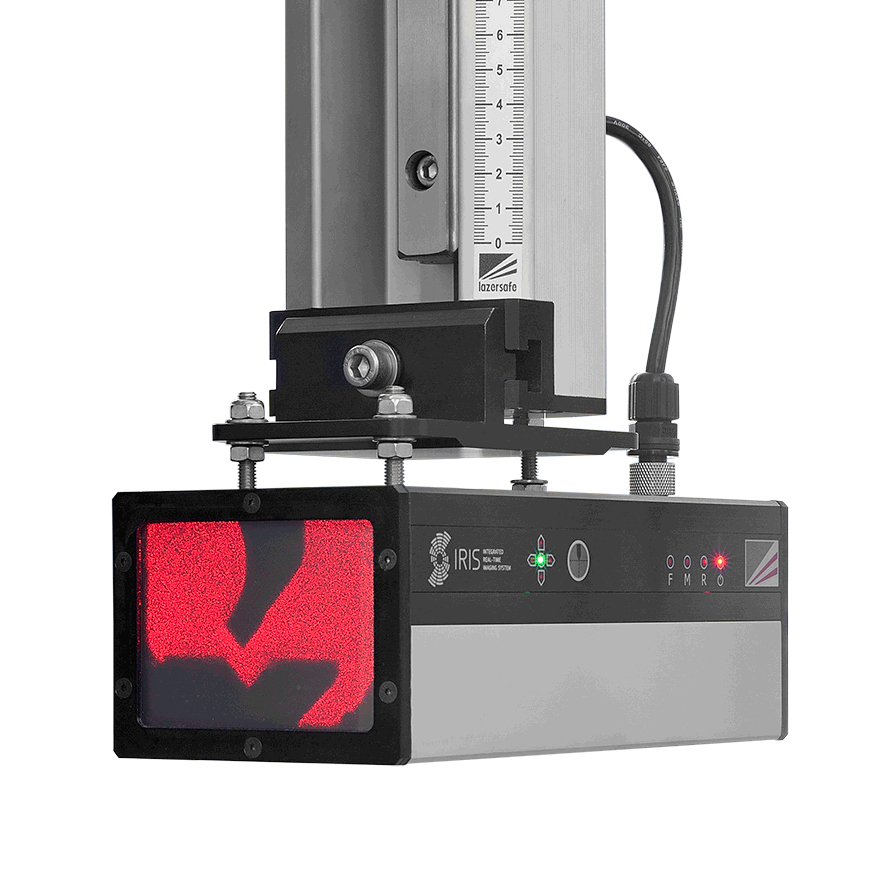

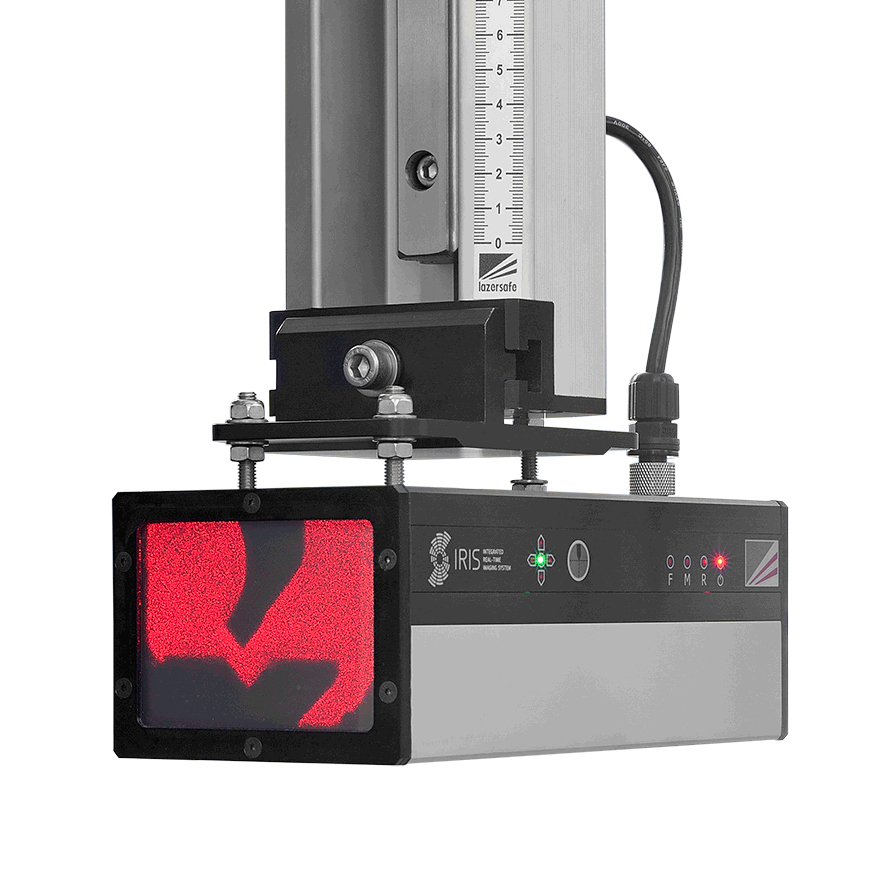

Laser safety system

Equipped as standard with a top-class laser safety system protecting the operator and significantly accelerating the bending process.

IRIS Plus laser system (option*)

The IRIS Plus laser system is an advanced safety and positioning solution for press brakes. It allows real-time measurement and angle correction, ensuring maximum accuracy and process efficiency.

We do not compromise on safety! High-quality hydraulic fittings and safety valves ensure compliance and reliability.

CE-compliant safety guards

Ergonomics and Additional Features:

- Mobile controller on articulated arm

- LED lighting for improved comfort and safety

- Linear guide supports

- Follow-up supports (option*)

Follow-up supports on servomotors enable bending of larger sheets that are automatically lifted to maintain the correct angle and shape during bending.

Our press brakes include numerous safety systems, clear markings, side and rear guards, and easily accessible emergency stop buttons.

Each machine is supplied with a comprehensive user manual.

SCO – Oil Cooling System

Standard feature ensuring stable machine operation parameters even during long-term continuous use.

Punch and die clamping:

- Standard four-sided multi-groove segmented dies and punches

- Manual AMADA (European) system for quick tool changes

- Side-mounted punches clamped with screws

Choice of die and punch

Proper selection of tools (die and punch) is essential for the final bending result.

CORMAK press brakes continuously measure bending parameters and automatically compensate deviations during the process to achieve optimal results.

Depending on the press force, segmented punches and dies may differ in length.

Included with the machine

Training and Machine Commissioning

It is possible to arrange professional training and machine commissioning carried out by a Cormak technician — this service is priced individually.

Contact our advisor to get more information.

Contact us

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.