CORMAK provides instructional videos on its YouTube channel that can be helpful during the first start-up of the device. These materials make it easy to familiarise yourself with the operation and key functions of our machines. Feel free to watch them to make getting started with our products easier!

Advantages of the laser welder

- Easy to use – thanks to its well-thought-out design and applied solutions, the operator can start working after a short training period.

- Low indirect radiation – only protective glasses are required to filter strong light during operation.

- Much faster welding compared to traditional methods – productivity can increase from 3 to 10 times.

- Concentrated beam: minimal structural change due to the small heat-affected zone.

- Repeatable welds – smooth seams and high joint strength.

- Capable of welding very thin materials, such as 0.5 mm stainless steel.

- Welding with or without wire (option*).

Technical specifications

| Maximum power |

2000 W |

| Laser wavelength |

1080 nm |

| Penetration depth (stainless steel 1 m/min) |

4.57 mm |

| Penetration depth (mild steel 1 m/min) |

3.59 mm |

| Penetration depth (aluminium 1 m/min) |

4.0 mm |

| Penetration depth (brass 1 m/min) |

4.0 mm |

| Welding speed |

0–120 mm/s |

| Automatic wire feeder |

Ø 0.8–1.6 mm |

| Maximum power consumption |

≤6.0 kW |

| Cooling system |

Water-cooled |

| Operating voltage |

230V |

| Shielding gas consumption |

approx. 10–12 L/mm Ø wire |

| Dimensions |

600 × 1100 × 1100 mm |

| Weight approx. |

185 kg |

THICKNESS OF WELDED MATERIALS

|

Material

|

WELDER POWER

|

| 1000 W |

1500 W |

2000 W |

3000 W |

| Stainless steel |

0.5–3.0 mm |

0.5–4.0 mm |

0.5–5.0 mm |

0.5–8.0 mm |

| Mild steel |

0.5–2.5 mm |

0.5–3.5 mm |

0.5–4.5 mm |

0.5–8.0 mm |

| Galvanised steel |

0.5–1.2 mm |

1.5–1.8 mm |

1.5–4.0 mm |

1.5–7.0 mm |

| Aluminium |

0.5–1.2 mm |

1.5–1.8 mm |

1.5–4.0 mm |

1.5–7.0 mm |

| Brass |

0.5–1.2 mm |

1.5–1.8 mm |

1.5–2.5 mm |

1.5–4.0 mm |

LATEST GENERATION WELDING HEAD

Automatic wire feeder included;

Adjustable spot size 0–5 mm;

High-power welding head;

Integrated connections for shielding gases and cooling system;

Interchangeable nozzles allow welding at various angles;

7 m fibre cable connecting the head with the welder;

Full ergonomics – lightweight and flexible design allows welding even in hard-to-reach areas;

Easy maintenance – quick and effortless replacement of the protective lens.

Automatic wire feeder included

The wire feeding system is synchronised with the welder’s software. Its task is to deliver filler material, enabling the operator to focus entirely on the welding process.

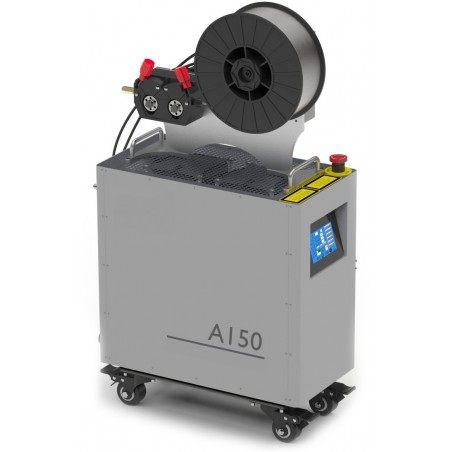

Set includes

- Laser welder with built-in cooling system

- Welding gun with adjustable focal length and full accessory set

- Fibre laser source

- Automatic wire feeder

- Set of cables

- Starter kit of nozzles and protective lenses for welding

The appearance of the housing may vary depending on the order date, but the technical specifications remain unchanged, ensuring consistent quality and performance. Additionally, designations WL and SL are used interchangeably depending on the machine series, which does not affect functionality or parameters.

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.