Drive System

- Powerful drive motors ensure high acceleration and precise positioning in all directions,

- X and Y axes equipped with high-quality rack-and-pinion transmission for durability and accuracy,

- Z-axis driven by a precision ball screw,

- All axes move on linear rail guides,

- Machine equipped with a tool height sensor.

Spindle

- High-performance brushless spindle designed for long-lasting operation,

- Liquid cooling system for stable temperature and extended spindle life,

- Precision bearings ensure quiet and smooth operation,

- Tool height measurement sensor included,

- Spindle speed range: 6,000–24,000 rpm.

Software

- OPTIONALLY latest UCanCAM V13 software (import/export from Corel, AutoCAD, etc.; text editor and multiple design tools),

- Allows fast, easy element design and automatic G-code generation,

- Includes G-code memory function – resumes machining from the last point after power loss, preventing material waste.

DSP Control

- Digital Signal Processing – advanced digital control ensuring smooth and accurate operation,

- DSP controller features an independent processor and memory, enabling reliable, stand-alone machine operation,

- Guarantees high precision and repeatability,

- No program reinitialization required after power loss,

- Built-in memory allows program execution without reloading files each time.

We supply machines with genuine CE certification – approved by leading EU authorities.

By choosing CORMAK, you choose machining precision, long service life, and operator safety.

We offer warranty and post-warranty service. Machine training and/or commissioning is available upon individual pricing — please contact our consultant.

The price quoted refers to the machine only and excludes additional equipment, installation, transport, and training.

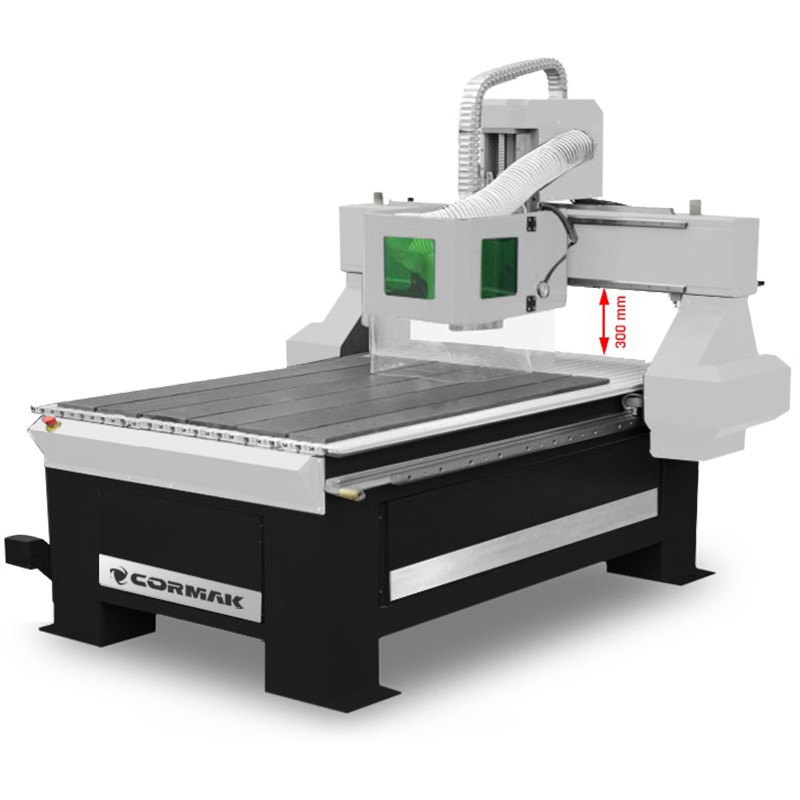

Technical Parameters

| Spindle |

2.2 kW / 3.0 kW (S1/S6) – 24,000 rpm, inverter-driven |

| Working area |

600 x 900 x 300 mm |

| Control system |

DSP |

| Program resolution |

0.001 mm |

| Power supply |

230 V |

| Weight |

310 kg |

| Machine dimensions |

1370 (W) x 1720 (L) x 2050 (H) mm |

| Table height |

750 mm |

| Guideways |

Linear |

| Drive transmission |

Rack and pinion (Z-axis – ball screw) |

| Axis drives |

Stepper motors |

| Software |

UCanCAM V13 (optional) |

Equipment

- Levelling feet,

- Bolts,

- Wrenches,

- Training cutter set,

- ER32 collets – 1/8”, 1/2”, and 5–6 mm.

Unloading and positioning of the machine are the customer’s responsibility.

Power plug provided by the customer due to varying 16A / 32A socket types.

On-site commissioning of CNC routers available upon request, with individual pricing.

2024-01-05

REWELACJA!

Zakupiłem prawie rok temu Frezarkę od CORMAK i jestem wciąż baaardzo zadowolony. Maszyna pracuje sporadycznie, ale wykonuje super ważne dla nas elementy. Największą zaletą tej maszyny jest jej prostota w obsłudze i zrozumieniu. idealnie wypełnia nasze potrzeby, frezujemy głównie w ALUMINIUM, czasem dla sprawdzenia, wymiarów elementu w drewnie.