- Reduced price

The basket is empty.

Efficient flat-bed CNC lathe for serial and small-batch production. The machine enables turning of external, internal, and spherical surfaces, as well as threading. Fixed cycles for cross, taper, and contour turning, threading, grooving, and facing are included in the Siemens control system, simplifying programming and significantly reducing machining time.

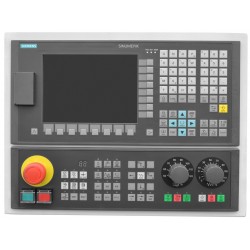

The CNC Lathe CORMAK CKT400x700 is an advanced numerical lathe designed for precise metal component machining in medium and large production plants. Equipped with Siemens Sinumerik 808D control and advanced machining cycles, it ensures high accuracy and productivity.

The CORMAK CKT400x700 CNC lathe for metal is a professional industrial solution that combines modern technology with a rigid structure, ideal for facilities requiring precise cutting operations. As an advanced industrial lathe, it enables complex operations such as external and internal turning, threading, grooving, drilling, and contouring while maintaining the highest quality of finished parts. Its key benefits include:

The industrial CNC lathe CORMAK CKT400x700 was designed for reliability and precision under demanding production conditions. Key structural components include:

The CNC Lathe CORMAK CKT400x700 delivers outstanding precision thanks to the Siemens Sinumerik 808D control system and Siemens servo drives with a torque of 5/7.5 Nm on the X/Z axes. Advanced fixed cycles such as facing, taper turning, threading and contouring simplify programming and shorten machining time. Positioning accuracy of 0.01 mm and repeatability of 0.012 mm guarantee the highest quality for parts up to 400 mm in diameter and 700 mm in length.

CNC lathes for metal such as the CKT400x700 are widely used across various industrial sectors, including:

The machine is an excellent choice for workshops seeking a versatile and reliable CNC lathe.

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training — please contact our consultant for more details.

| Technical Specifications | |

| Turning diameter over bed | 400 mm |

| Turning diameter over carriage | 160 mm |

| Distance between centres | 700 mm |

| Spindle speed | 150–1,800 rpm |

| Spindle bore | Ø 48 mm |

| Positioning accuracy | 0.01 mm |

| Repeatability accuracy | 0.012 mm |

| Spindle nose | A2-6 |

| Torque X/Z axis | 5/7.5 Nm |

| Number of tools | 8 |

| Tool size | 20x20 mm |

| Tailstock taper | MK5 |

| Maximum tailstock travel | 100 mm |

| Tailstock quill diameter | Ø 60 mm |

| Main motor power | 5.5 kW |

| Dimensions | 2,200x1,100x1,620 mm |

| Weight | 1,800 kg |

The CNC Lathe CORMAK CKT400x700 is available with advanced CNC control systems such as Siemens Sinumerik 808D, Siemens Sinumerik 828D, and Fanuc Oi-TF, which guarantee precision, reliability, and ease of operation:

With over 20 years of experience in supplying industrial machinery, CORMAK provides reliable CNC lathes for metal and comprehensive technical support. Our machines meet European safety standards, while professional warranty and post-warranty service ensure uninterrupted production.

Ask for details or schedule a machine demonstration!

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Serrated Soft Jaws for Lathe Chucks

Serrated soft jaws are designed for precise clamping of workpieces in lathe chucks. Thanks to their soft material structure, they can be pre-machined to match a specific shape or diameter, ensuring perfect fit and repeatability in series production. The serrated connection provides stable seating ...More

Hard Top Jaws SGTm for Lathe Chucks

The SGTm hard top jaws are designed for secure and stable clamping of workpieces during machining. Made of hardened tool steel, they provide excellent wear resistance, making them ideal for demanding production environments. Perfect for applications requiring high clamping force and stability during turning. ...More

CNC Lathe CORMAK 800x3000 SIEMENS SINUMERIK

The CNC Lathe CORMAK 800x3000 from the heavy-duty series guarantees efficiency in high-precision metal cutting. This machine is not just a tool but a partner for both experienced professionals and those starting their journey in production. Its power and stability, supported by wide guideways, make ...More

CNC Lathe CORMAK CKT 800x5000 SIEMENS SINUMERIK

The CORMAK CKT800x5000 CNC lathe is an excellent choice for both experienced professionals and those starting work in serial or single-unit production. This heavy-duty lathe series has been designed for maximum cutting efficiency, guaranteeing superb results even under intensive operation. ...More

CNC Lathe CORMAK 660x3000 SIEMENS SINUMERIK

Our unique CNC Lathe CORMAK CKT660x3000 is an excellent solution for experienced professionals as well as those beginning their journey in batch and single-piece production. This series of heavy-duty lathes has been designed for efficient metal cutting, with wide guideways and a robust structure ...More

CNC Lathe CORMAK 800x2000 SIEMENS SINUMERIK

Our CNC Lathe CORMAK 800x2000 from the heavy-duty series is the perfect tool for professionals and beginners engaged in batch or single-piece production. Its wide guideways and rigid structure provide not only stability but also excellent turning accuracy and high machining repeatability. Combining ...More

CNC Lathe CORMAK CKT360x1000 with Hydraulic Chuck and SIEMENS SINUMERIK

The CORMAK CKT360x1000 CNC lathe is a perfect solution for companies requiring precise turning across various applications. Designed for quality and performance, this machine enables fast machining while maintaining the highest standards. ...More

CNC Lathe CORMAK 1200x1500/2000/3000 SIEMENS SINUMERIK

Industrial lathe for high-precision cutting, designed for both serial and single-part production. The rigid structure and heavy-duty hardened and ground guides ensure stability, machining accuracy and repeatability when processing large-size components. ...More

CNC Lathe CORMAK 320x1000 Manual Chuck SIEMENS SINUMERIK

Discover the potential of the CORMAK 320x1000 CNC Lathe – a metalworking machine featuring a rigid cast-iron bed that eliminates vibrations, with induction-hardened and ground guideways ensuring unmatched accuracy and durability. The bed is a solid cast-iron structure resistant to vibration, with hardened and precision-ground guides. ...More

CNC Lathe CORMAK CKT660x1500 SIEMENS SINUMERIK.

Our reliable CNC Lathe CKT660x1500 is the key to perfect metal machining. Designed for both professionals and beginners, this series of heavy-duty lathes offers not only efficient cutting but also wide application in both serial and single-piece production. ...More

CNC Lathe CORMAK 320x750 Manual Chuck SIEMENS SINUMERIK

Discover the reliability and versatility of the CORMAK CNC Lathe 320x750 – ideal for precise machining of metal and other materials. With a solid cast-iron structure resistant to vibrations and induction-hardened, ground guideways, this machine ensures outstanding accuracy and long service life. ...More

CNC Lathe CORMAK CKT360x750 Manual Chuck SIEMENS SINUMERIK

CKT series flat-bed CNC lathes are characterised by high efficiency in serial machining. Depending on the version, they can be equipped with a manual or hydraulic chuck with a diameter of 160mm or an optional 200mm. The CNC machine enables turning of external, internal, and spherical surfaces and ...More

CNC Lathe CORMAK CKT 800x4000 SIEMENS SINUMERIK

The CORMAK CKT800x4000 CNC lathe is a reliable solution for both experienced professionals and those starting out in serial and single-unit production. Designed for maximum cutting efficiency, it delivers excellent results even under intensive use. Thanks to its robust construction and wide ...More

CNC Lathe CORMAK 660x3000 SIEMENS SINUMERIK

Our unique CNC Lathe CORMAK CKT660x3000 is an excellent solution for experienced professionals as well as those beginning their journey in batch and single-piece production. This series of heavy-duty lathes has been designed for efficient metal cutting, with wide guideways and a robust structure ...More

CNC Lathe CORMAK CKT 630x6000 SIEMENS SINUMERIK

Our exceptional CNC Lathe CKT630x6000 is the perfect solution for both experienced professionals and those starting out in serial and single-part production. This series of heavy-duty lathes has been designed for maximum cutting performance , ensuring optimal results even under intensive ...More

CNC Lathe CORMAK CKT630x5000 SIEMENS SINUMERIK

Our exceptional CNC Lathe CKT630x5000 is the perfect solution for both experienced professionals and those starting out in batch or single-piece production. This series of heavy-duty lathes has been designed for maximum cutting efficiency , ensuring optimal performance even under intensive ...More

CNC Lathe CORMAK CKT560x1500 SIEMENS SINUMERIK

Efficient flat-bed CNC lathe designed for a wide range of applications, dedicated to both serial and single-part production. The rigid machine structure and massive hardened and ground guideways ensure stability, turning accuracy and high repeatability in machining large components. ...More