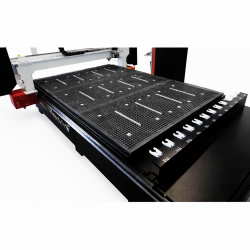

1. Worktable

- Sectional vacuum table with six independent zones made of durable HPL plates, controlled directly from the control cabinet,

- Each section features vacuum ports connected to the central vacuum pump system,

- Main ports include removable caps, allowing flexible clamping of various workpiece sizes,

- The table surface is covered with a network of channels ensuring even vacuum distribution,

- Includes T-slots for manual material clamping,

- Equipped with pneumatic positioning stops on two axes — ensuring consistent and repeatable material placement,

- The IND series features a reinforced industrial table providing superior rigidity.

2. Spindle

- High-performance 9 kW brushless spindle from a renowned Italian manufacturer, inverter-driven with overload protection,

- Air-cooled HSD spindle for high-duty industrial operation,

- Supports automatic tool change (ATC) to minimize downtime,

- Automation allows seamless tool utilization without recalibration or production interruption.

3. Drive System

- Energy-efficient YASKAWA AC servo drives controlled by a digital controller, ensuring high-speed and precise machining,

- Brushless AC servo motors on X and Y axes transmit motion via planetary gearboxes,

- Z-axis precision drive via reinforced ball screw,

- Portal movement along X and Y axes guided by HIWIN linear rails and helical gears made of hardened steel,

- All axes equipped with certified HIWIN trapezoidal linear guides, individually tested during assembly,

- Central automatic lubrication system for guides and ball screw ensures maintenance-free operation and extended component life.

4. Construction

- Sliding gantry structure made of cast iron for maximum rigidity and vibration damping,

- Reinforced ribbed steel table eliminates vibration during heavy-duty machining.

5. Tool Magazine and Measurement

- 12-position linear tool magazine with ISO30 holders and ER32 collets,

- Supplied with tool holders and collets: 1/2" (6 pcs), 1/8" (2 pcs), 3–4 mm (2 pcs), 5–6 mm (4 pcs), 7–8 mm (2 pcs), 9–10 mm (2 pcs),

- Equipped with an automatic Z-axis tool height sensor that eliminates manual calibration and ensures measurement precision.

6. Software and Industrial Control

- Controlled by the SYNTEC industrial controller, identical to those used in CNC machining centers, complete with LCD display and hand pendant,

- Optional UCanCAM V13 software (imports Corel, AutoCAD files; supports G-code generation and editing),

- Enables quick design and conversion of elements into machining code, with easy import from other CAD programs.

7. Vacuum Pump (optional) and Dust Extraction Foot

- New-generation dust extraction housing allows efficient chip removal,

- Vacuum pump ensures secure material clamping during machining,

- Optional 7.5 kW vacuum pump (max -440 mbar) with six independent zones,

- Pneumatically actuated dust extraction foot mounted near the spindle keeps the work area clean and precise.

All CORMAK machines are CE-certified by leading EU authorities.

By choosing CORMAK, you invest in precision, long service life, and operational safety.

Warranty and post-warranty support available. Training and on-site commissioning offered on request — please contact our consultant.

The price refers to the machine only, excluding additional equipment, installation, transport, and training.

Technical Parameters

| Working area |

2100 x 3100 mm |

| Z-axis travel |

300 mm |

| Construction |

Gantry – cast iron / Table – welded steel |

| Drives |

Hybrid AC servo motors (LEADSHINE) 1500 W |

| Table |

Hybrid vacuum / T-slot |

| Spindle power |

9 kW |

| Gearbox |

Shimpo |

| Spindle speed |

6,000 – 24,000 rpm |

| Power supply |

400 V, compressed air min. 8 bar |

| Repositioning accuracy |

0.01 mm |

| Linear bearings |

HIWIN trapezoidal rails and carriages |

| Material clamping |

Vacuum / hybrid |

| Vacuum pump |

Optional 7.5 kW, 8 independent zones |

| Software |

(optional) UCanCAM V13 – Polish version |

The machine is equipped with a G-code memory function — in case of power loss, it resumes machining from the last point without wasting time or material.

Optional Z-axis gantry height increase up to 450 mm.

Feed-in/out tables (loading/unloading) as in HK-51 and HK-52 models.

* Depending on material type and machining, using two vacuum pumps is recommended for improved holding efficiency.

* Unloading and installation of the machine are the customer’s responsibility.

** Power plug supplied by the customer due to varying 16A / 32A standards.

On-site commissioning of CNC routers available upon request, with individual pricing.