- On sale!

The basket is empty.

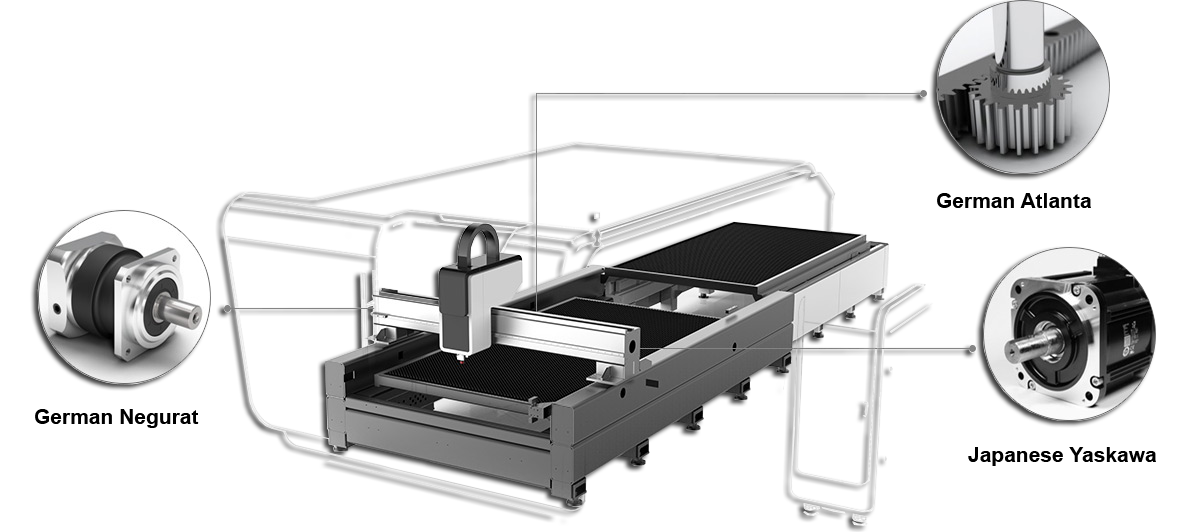

Modern, fully enclosed fibre laser cutting machine for sheet metal cutting. The laser housing with protective glass windows provides full protection against laser beam reflection, ensuring operator safety. Available in power options from 1000W to 12000W. High-quality components guarantee long-term, reliable and maintenance-free operation of the fibre laser.

Laser cutting machines are modern devices offering numerous advantages. They are not only an excellent and much more cost-effective alternative to CO2 technology but also provide many benefits that enable production expansion (up to 70%) and improved quality. FIBER technology allows cutting of sheets and other materials of various thicknesses, from very thin to very thick. The wavelength of the FIBER laser is 1.064 micrometres. These features result in beam intensity that is 100 times higher than that of CO2 machines of comparable power.

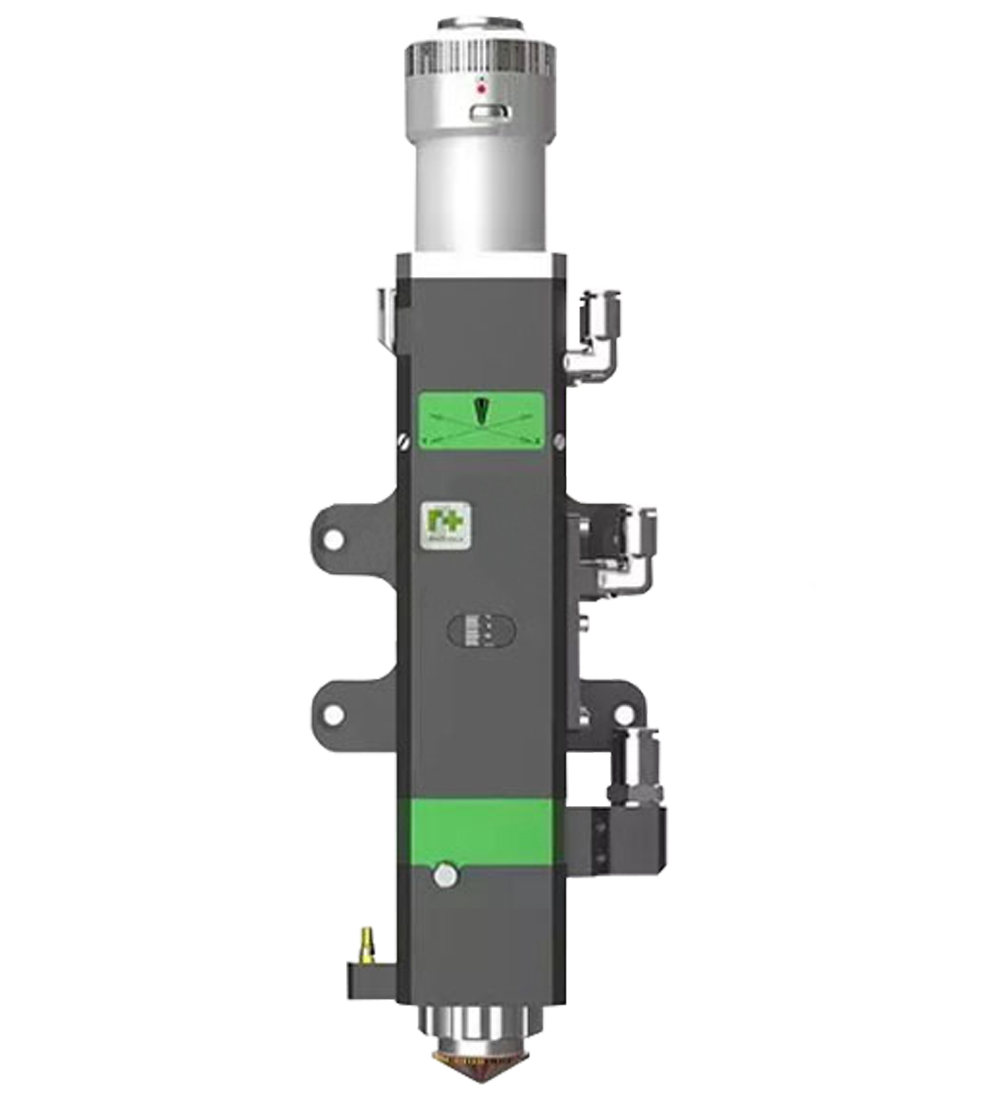

The sliding gantry structure is made of aged aerospace aluminium, formed under 4,300 tons of pressure to achieve exceptional rigidity. Aerospace aluminium offers numerous advantages: high stiffness (greater than cast iron), light weight, corrosion and oxidation resistance, and excellent machinability.

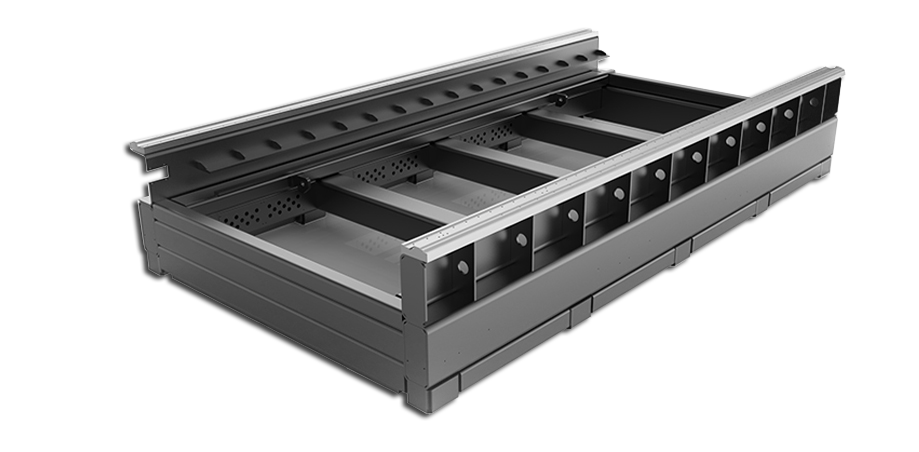

The exchangeable work table consists of upper and lower platforms, the movement and exchange of which are controlled by the system. The machine can complete the platform exchange process within 15 seconds.

The bed structure features an internal honeycomb design made of multiple welded rectangular tubes. Internal reinforcements increase the bed’s durability as well as the rigidity and stability of the guide rail, effectively preventing deformation. High strength, stability, and tensile resistance ensure 20 years of operation without distortion.

| WORKING AREA | 2500x6000 |

| POWER | 1000W 2000W 3000W 4000W 6000W 12000W |

| REPEATABLE POSITIONING ACCURACY | ±0.02 mm/m |

| MAXIMUM SPEED | 120 m/min |

| MAXIMUM ACCELERATION | 1.5G |

| POWER SUPPLY | 400V 50Hz |

Actual parameters may vary depending on technical conditions and materials used.

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Laser Welding Machine CORMAK WL2000 3in1 – Special Offer

We present the latest industrial laser welding machine CORMAK WL2000, which combines advanced FIBER technology with innovative design solutions, offering unmatched precision and performance. Designed for welding various types of metals, it ensures top-quality and repeatable welds. Thanks to its ...More

The set includes the THEOR H1520 COMPACT screw compressor with an integrated air dryer and a vertical 500L compressed air receiver. The CORMAK THEOR series screw compressors combine the latest pneumatic technologies with high-quality materials and components. Low operating costs, easy operation, ...More

Fully Enclosed Fibre Laser Cutting Machine CORMAK FIBER LF4020GA

Modern, fully enclosed FIBER laser for cutting sheet metal. The laser housing with protective glass ensures complete protection against laser beam reflections, safeguarding the operator and other personnel. Available with power from 1000W to 8000W, equipped with top-quality components ensuring ...More

Fibre Laser Cutter CORMAK FIBER 3015P

The latest premium-class fibre laser cutting machine. The fully enclosed FIBER laser is equipped with a camera for real-time process monitoring and control. The use of components from leading global manufacturers ensures long service life and reliability. A wide range of available laser power options from 1kW to 8kW. ...More

Tube and Profile Fibre Laser Cutting Machine CORMAK FIBER LF3015GEPR 6kW

The fibre laser cutting machine is equipped with a rotary attachment for tubes and profiles up to 200 mm in diameter and 6000 mm in length, as well as an exchangeable table system. One machine – two applications. It is an ideal solution for companies with limited workspace. YASKAWA servomotors ...More

Fibre Laser Cutter CORMAK FIBER LF3015C

Modern, fully enclosed fibre laser cutter for cutting metal sheets up to 3000×1500 mm. The side-opening design ensures convenient loading of sheets onto the worktable. Thanks to its compact size, it is ideal for production halls with limited space, where larger laser systems with exchange tables cannot be installed. ...More

Fibre Laser Cutter CORMAK FIBER LF3015GEP 2000W

Fully enclosed, modern fibre laser cutter designed for sheet metal cutting. The protective enclosure with safety glass ensures complete protection against laser beam reflection, safeguarding the operator and all personnel nearby. Available with power options from 1000W to 12000W. Premium-quality ...More

Fibre Laser Cutter CORMAK FIBER LF12025GEP

Fibre laser cutter with a working area of 12,000x2,500 mm and an exchangeable table system — the ideal solution for industrial applications where speed, quality and operational stability are essential. Each laser is assembled at our factory, and together with advanced design, high-quality ...More

Fully Enclosed Fibre Laser Cutting Machine CORMAK FIBER LF6020GEP 6000W

Fully enclosed, modern fibre laser cutting machine for sheet metal cutting. The enclosure with protective glass windows ensures full protection against laser reflection, safeguarding the operator and others in the workspace. Available in power options from 1000W to 12000W. Top-quality components ...More

Fully Enclosed Fibre Laser Cutting Machine CORMAK FIBER LF6020GEP 12000W

Fully enclosed and modern fibre laser cutting machine for sheet metal processing. The enclosure with protective windows provides complete safety against laser reflection, protecting the operator and bystanders. Available in power variants from 1000W up to 12000W. High-quality components ensure long ...More

Fibre Laser Cutter CORMAK FIBER LF1310GEP4 High Precision 1000W

Fibre laser cutter with exceptional cutting precision. The FIBER laser is equipped with HIWIN linear guides and TBI ball screws mounted on both sides of the cutter. The use of these components ensures outstanding quality even at high cutting speeds. The laser housing complies with all safety ...More

Fully Enclosed Large-Format Fiber Laser Cutter FIBER LF12025GH / LF10025GH 20kW

The ultra-fast, fully enclosed large-format fiber laser cutter is designed for industrial applications. With a 20 kW laser source, it can cut sheets up to 70 mm thick. Modern design solutions significantly reduce processing time while increasing productivity and operational efficiency. ...More

Fully Enclosed Fibre Laser Cutting Machine CORMAK FIBER LF4020GH / LF6025GH 20000W

The FIBER Laser is equipped with linear motors, achieving extremely high cutting speeds. The 20kW laser source enables cutting plates up to 70 mm thick. Innovative engineering solutions significantly reduce processing time while increasing performance, efficiency, and precision. ...More

Tube and Profile Fibre Laser Cutting Machine CORMAK FIBER LF3015GEPR 4kW

The fibre laser cutting machine is equipped with a rotary attachment for tubes and profiles up to 200 mm in diameter and 6000 mm in length, as well as an exchangeable table system. One machine – two applications. It is the ideal solution for companies with limited workspace. YASKAWA servomotors ...More

Fibre Laser Cutter CORMAK FIBER LF3015GEP 4000W

Fully enclosed, modern fibre laser cutter for sheet metal cutting. The protective enclosure with safety glass ensures complete protection against laser beam reflection, safeguarding the operator and nearby personnel. Available with power options from 1000W to 12000W. Top-quality components ensure ...More

Fully Enclosed Fibre Laser Cutting Machine CORMAK FIBER LF4020GEP 12000W

Modern, fully enclosed FIBER laser for cutting sheet metal. The sealed housing with protective glass provides full protection against laser beam reflections, ensuring the safety of the operator and others in the workspace. Available in power options from 1000W to 12000W. Premium components ...More

Fully Enclosed Fibre Laser Cutting Machine CORMAK FIBER LF6020GEP 3000W

Fully enclosed and modern fibre laser cutting machine for sheet metal cutting. The enclosure with protective windows ensures complete protection against laser reflection, safeguarding the operator and other personnel. Available in power variants from 1000W to 12000W. High-quality components ...More

Fibre Laser Cutter CORMAK FIBER LF3015GEP 6000W

Modern, fully enclosed fibre laser cutter designed for sheet metal cutting. The enclosure with protective glass ensures complete protection against laser beam reflection, safeguarding the operator and other personnel in the workspace. Available with power options from 1000W to 12000W. Top-quality ...More

Write your review

* Required fields

I accept privacy policy rules