Laser cutting machines are modern devices offering numerous advantages. They are not only an excellent and more cost-effective alternative to CO2 technology but also provide many benefits that enhance production efficiency (up to 70%) and improve quality. FIBER technology enables cutting sheets and other materials of various thicknesses — from very thin to very thick. The wavelength of a FIBER laser is 1.064 micrometres, providing an intensity 100 times higher than that of CO2 machines of similar power.

Main advantages of the laser:

- maintenance-free optical fibre,

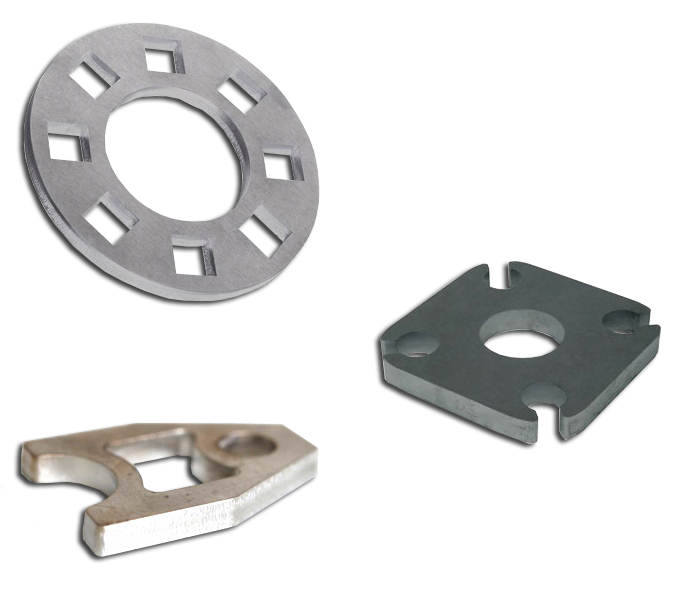

- no wearing components,

- the fibre laser source occupies about one-third less space,

- high energy efficiency – 100,000 h of operation,

- universal use (special steels, mild and stainless steel, copper, brass, aluminium, titanium).

Fibre laser

- increases work efficiency by 80%,

- reduces maintenance costs by 70%,

- saves 80% of energy,

- minimises gas consumption,

- saves 30% of workshop space.

Safety and Clean Operation

- fully enclosed laser structure,

- observation window with CE-standard protective laser glass,

- cutting fumes can be filtered internally — environmentally friendly and safe.

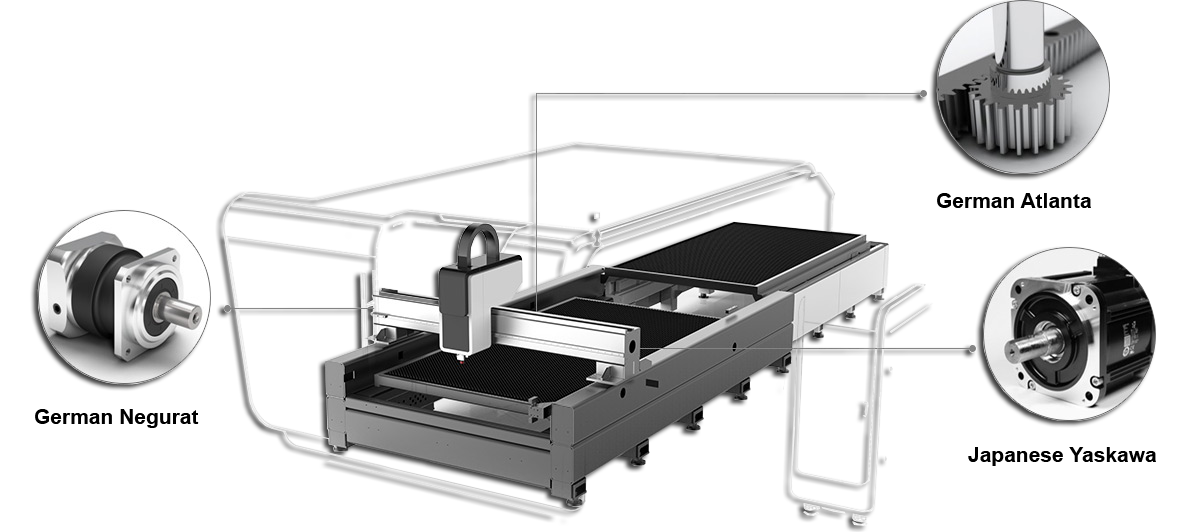

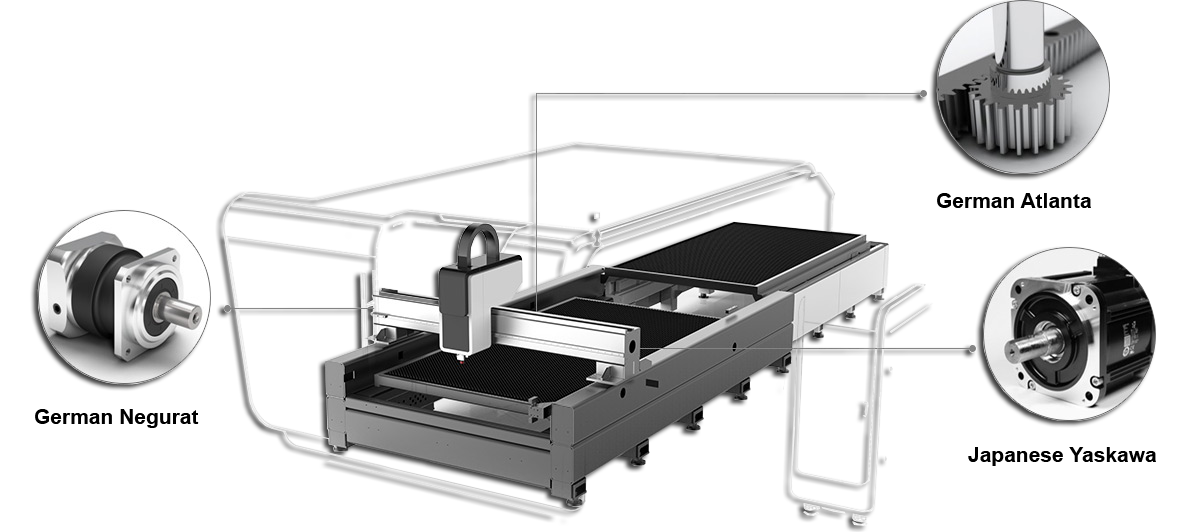

Sliding Gantry Made of Aged Aerospace Aluminium

The gantry is made of aged aerospace-grade aluminium, formed under 4,300 tonnes of pressure, providing exceptional rigidity. Aerospace aluminium offers many benefits: high stiffness (greater than cast iron), low weight, corrosion and oxidation resistance, and excellent machinability.

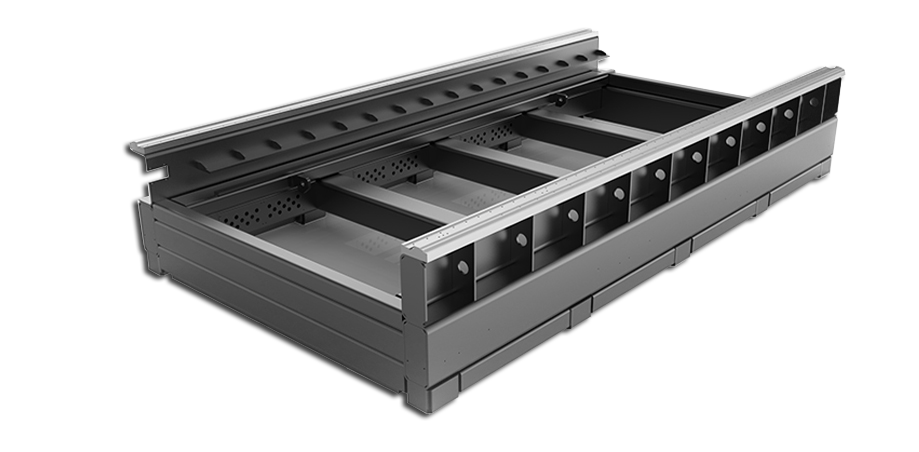

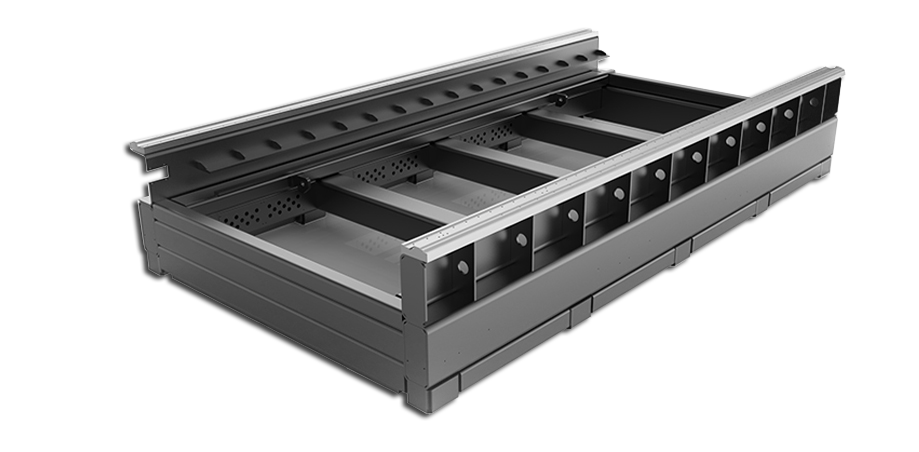

Exchangeable Working Table

The exchangeable working table consists of upper and lower platforms, controlled by the CNC system. The machine can perform a complete platform exchange within 15 seconds.

Welded Rectangular Frame Bed

The bed structure features an internal honeycomb design made of multiple welded rectangular tubes. Internal reinforcements improve strength, rigidity, and stability of the guide rails, effectively preventing deformation. High durability and tensile strength ensure 20 years of distortion-free operation.

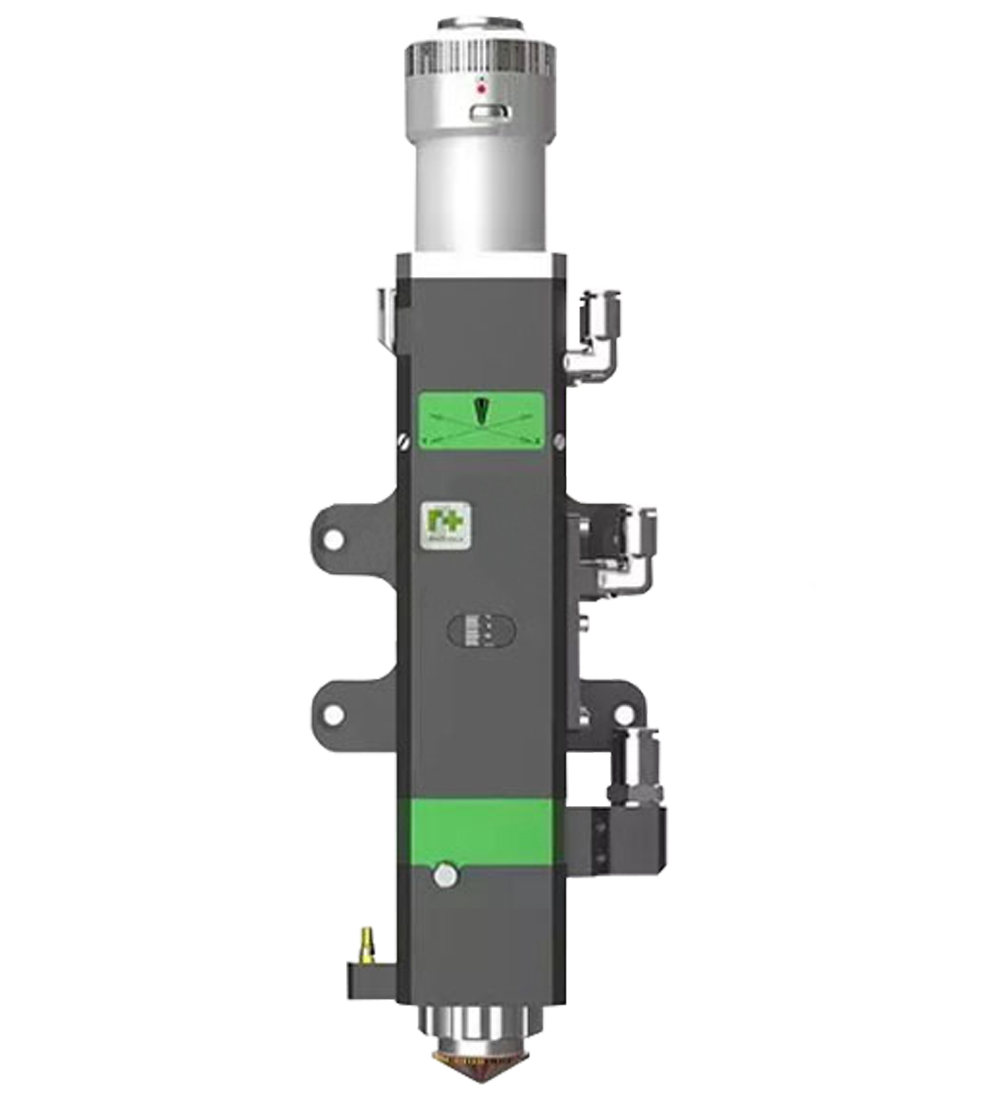

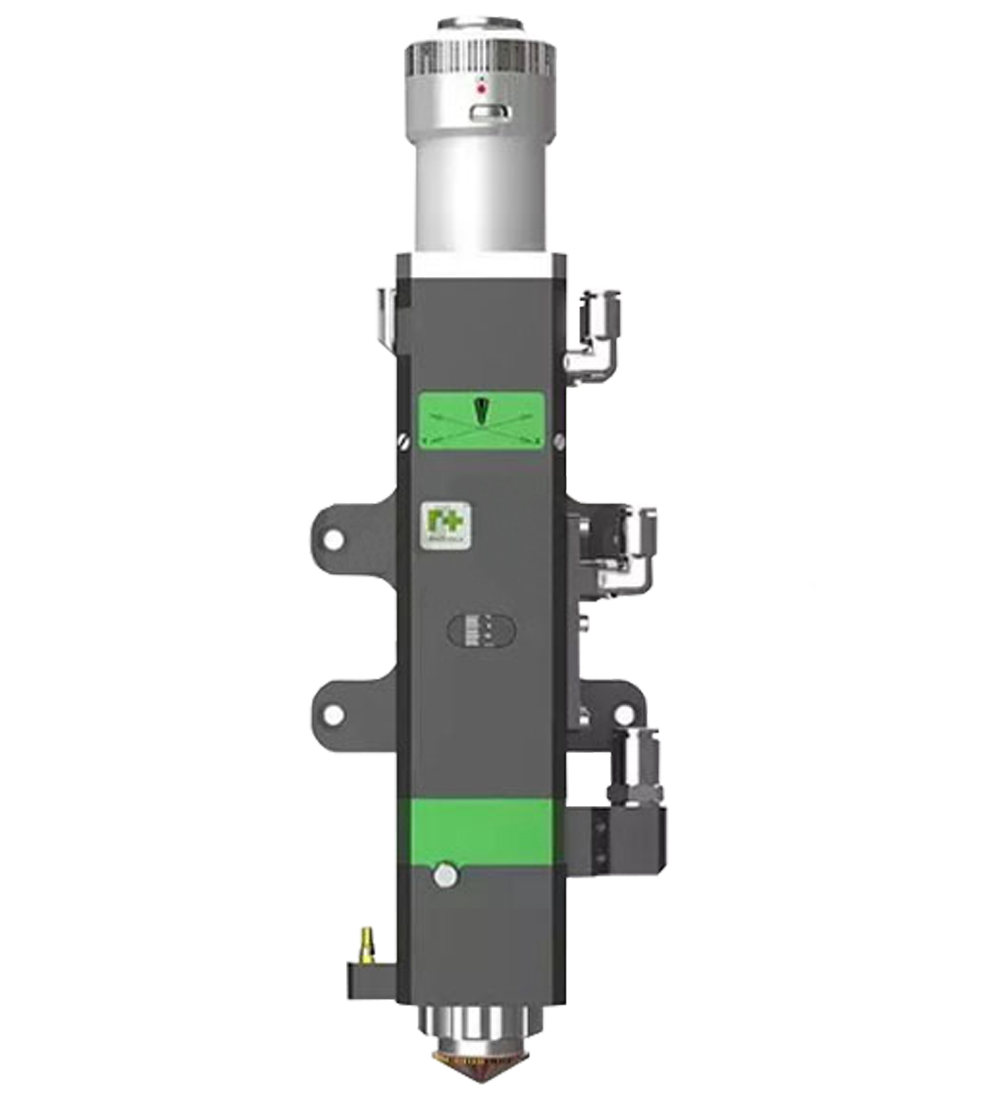

Raytools Cutting Head

- Automatic focus adjustment – autofocus. The software automatically adjusts the focusing lens when cutting sheets of different thicknesses. The automatic focus adjustment speed is ten times faster than manual adjustment.

- Wider manual adjustment range – adjustment range -10 mm to +10 mm. Precision of 0.01 mm allows use with materials from 0–20 mm (below 1500W).

- Long service life. Collimating and focusing lenses have water-cooled radiators that reduce cutting head temperature, extending its lifespan.

Technical Parameters

| WORKING AREA |

2000x4000 |

| POWER |

1000W 2000W 3000W 4000W 6000W 8000W |

| REPEAT POSITIONING ACCURACY |

±0.02 mm/m |

| MAXIMUM SPEED |

120 m/min |

| MAXIMUM ACCELERATION |

1.5G |

| DIMENSIONS |

10800x3350x2310 mm |

| POWER SUPPLY |

400V 50Hz |

Cutting Parameters

Actual parameters may vary depending on technical conditions and materials used.

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.

Write your review

* Required fields

I accept privacy policy rules