MILL 640 Machining Centre – Precision and reliability in CNC machining

The MILL 640 Machining Centre is an advanced vertical CNC machining centre designed for precise metalworking in demanding industrial environments. With its solid construction and modern technologies, the machine offers high performance, durability and flexibility for a wide range of machining applications.

Main advantages of the MILL 640 machining centre

The MILL 640 Vertical Machining Centre stands out for its combination of precision, power and versatility, making it an ideal solution for production facilities looking for a reliable metal milling centre. Designed for intensive use, it delivers advanced machining capability while maintaining the highest quality standards.

- Exceptional precision: Equipped with high-quality linear guides and a positioning accuracy of 0.01 mm, the machine guarantees excellent surface finish and detail quality.

- High performance: A powerful 4 kW spindle (optional 5 kW or 7.5 kW) with speeds up to 8000 rpm (optional 10,000 rpm) ensures efficient machining of various materials.

- Durability and stability: The rigid machine frame minimises vibration, maintaining stability even under maximum table load (300 kg).

- Safety and ergonomics: The sealed work chamber protects the operator from dust and debris, creating a safe and clean working environment.

- Configurable flexibility: A wide range of optional equipment, such as through-spindle cooling or a 4th axis, allows the machine to be tailored to specific production needs.

- Intuitive control: Advanced CNC systems such as Siemens Sinumerik or Fanuc Oi-TF provide easy operation and precise programming.

Construction and technology

The MILL 640 CNC machining centre is designed for maximum durability and accuracy. Key structural elements include:

- Rigid frame: The solid structure reduces vibration, ensuring stability and extending the machine’s service life.

- Linear guides: Premium guides on the X, Y and Z axes ensure smooth motion and 0.01 mm precision.

- BT40 spindle: Durable spindle with 4 kW power (optional 5 kW or 7.5 kW) and speeds up to 8000 rpm (optional 10,000 rpm) for machining a wide range of materials.

- Siemens servo drives: Ensure smooth and dynamic movement, contributing to high machining efficiency.

- Sealed work chamber: Protects against dust and contamination, ensuring operator safety and a clean work area.

- Closed cooling system: Effectively dissipates heat to maintain optimal spindle operating conditions.

- Automatic lubrication system: Extends the life of moving components and reduces maintenance costs.

Precision and performance

CNC machining centres like the MILL 640 deliver exceptional accuracy and productivity. With positioning accuracy of 0.01 mm and a feed rate range of 1–10,000 mm/min, the machine performs complex milling operations efficiently. Advanced CNC controls enable precise programming and toolpath optimisation, reducing cycle times and improving component quality.

Applications of the metalworking centre

Vertical machining centres MILL 640 are used across many industries, including:

- Automotive: Production of precision parts such as engine, gearbox and suspension components.

- Aerospace: Machining of lightweight alloys and high-strength materials such as titanium and aluminium.

- Machine building: Manufacturing of moulds, dies and components requiring extreme precision.

- Small and medium-sized enterprises: Perfect for both serial and single-part production due to its flexibility and ease of operation.

This machine is an excellent choice for manufacturers seeking a reliable machining centre for precision metalworking and general industrial applications.

Technical parameters

| Table size |

700x400 mm |

| Distance from spindle nose to table surface |

120–520 mm |

| Distance from spindle axis to column |

450 mm |

| Table travel (X/Y) |

600 x 400 mm |

| Z-axis travel |

400 mm |

| Spindle taper |

BT40 |

| Spindle speed |

up to 8000 rpm (option 10,000 rpm) |

| T-slots / width / spacing |

4 / 18 / 85 mm |

| Feed rate |

1–10,000 mm/min |

| Feed drive power (torque) |

1.5 / 1.5 / 2.5 kW |

| Spindle motor power |

4 kW (option 5 kW or 7.5 kW) |

| Max. table load |

300 kg |

| Machine weight |

3500 kg |

Standard equipment

- SIEMENS SINUMERIK 808 Advanced control

- 8000 rpm spindle

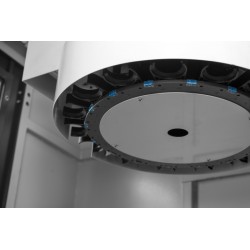

- 16-tool magazine

- Three-colour warning lights

- Lighting

- Closed cooling system

- Sealed machine enclosure

- Automatic lubrication system

- Pneumatic system

Optional equipment*

- SINUMERIK 828D control

- FANUC Oi-TF control

- Horizontal 24-tool magazine

- Through-spindle cooling

- 10,000 rpm spindle

- Chip conveyor

- Tool measuring probe

- Workpiece probe

- 4th axis

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training — please contact our consultant for more details.

CNC Controls – Siemens and Fanuc

The MILL 640 machining centre offers advanced CNC systems that ensure precision, reliability and user-friendly operation. Available options include:

SIEMENS SINUMERIK 808 Advanced

An economical control for smaller workshops, offering an intuitive interface, high reliability and compatibility with basic milling applications.

Siemens Sinumerik 828D

An advanced system for demanding processes, featuring high computing power and full CAD/CAM integration capabilities.

Fanuc Oi-TF

A reliable system dedicated to turning and milling operations, known for outstanding stability and advanced functionality.

User manuals

SIEMENS SINUMERIK 828/840

Download manual

SIEMENS SINUMERIK 808

Download manual

2024-11-07

Wysoka jakość i precyzja

Zdecydowanie polecam! Solidna konstrukcja, dokładność i duża przestrzeń robocza.