The basket is empty.

Our CNC Machining Centre CORMAK MILL1055 combines strength and innovation. Designed for long-term use, it merges proven components with modern technology. The massive cast-iron body ensures both performance and precision, while the sealed work chamber maintains cleanliness and operator safety. The hardened worktable supports heavy components without stressing the mechanical structure, and the efficient cooling system guarantees optimal cutting conditions.

The MILL1055 machining centre is an advanced vertical CNC machining centre designed for precise metalworking in demanding industrial applications. With its robust construction and modern technology, this machine guarantees reliability, high performance, and excellent quality of finished parts.

The vertical machining centre MILL1055 stands out with advanced technological solutions providing an advantage in the production of precision components. It is an ideal choice for companies seeking CNC machining centres that combine precision, durability, and efficiency. Key benefits include:

The MILL1055 vertical milling centre has been designed for maximum durability and precision under demanding industrial conditions. Key structural components include:

The CNC machining centre MILL1055 offers outstanding precision through advanced design and control technology. Positioning accuracy of 0.02 mm and rapid feed rates of 30/30/24 m/min allow for efficient machining of complex, high-tolerance parts. The standard Siemens Sinumerik 828D control optimises tool paths, reduces machining time, and minimises production errors.

Vertical machining centres like the MILL1055 are used in a wide range of industries, including:

The MILL1055 is the perfect solution for medium and large manufacturing facilities that prioritise quality, repeatability, and efficiency.

*The quoted price refers to the machine itself, excluding optional or additional accessories, installation, transport and training — please contact our consultant for details.

| Spindle taper | BT40 |

| Table size | 1000×550 mm |

| Distance spindle nose – table surface | 150–700 mm |

| Distance spindle axis – column | 560 mm |

| Travel X/Y/Z | 800×550×500 mm |

| Z-axis travel range | 550 mm |

| Spindle speed range | 10,000 rpm |

| T-slots (number × width × pitch) | 5 × 18 mm × 90 mm |

| Rapid feed X/Y/Z | 30 / 30 / 24 m/min |

| Feed rate | 2.5–3000 mm/min |

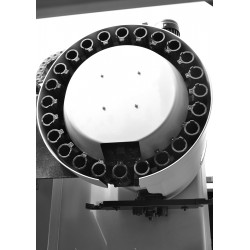

| Tool magazine capacity | 24 |

| Positioning accuracy | 0.02 mm |

| Spindle motor power | 7.5 kW |

| Power supply | 400 V |

| Maximum table load | 500 kg |

| Machine weight | 5000 kg |

| Overall dimensions (L×W×H) | 2550×2420×2790 mm |

The MILL1055 machining centre is equipped with advanced CNC control systems including Siemens Sinumerik 808D, Siemens Sinumerik 828D and Fanuc Oi-TF, ensuring accuracy, reliability and intuitive operation.

With over 20 years of experience in delivering industrial machinery, CORMAK provides reliable machining centres and full technical support. Our machines comply with European safety standards, and professional after-sales service ensures uninterrupted production. Contact us to learn more!

Ask for details or book a machine demonstration!

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

MILL 1055 1000x550 spełnia wszystkie oczekiwania – szybka, wydajna, niezawodna.

Maszyna pracuje bardzo stabilnie, idealna do wymagających zadań.

Duża przestrzeń robocza i sterowanie Sinumerik 828 to świetne połączenie.

MILL 1055 to bardzo precyzyjne centrum obróbcze – praca na nim to czysta przyjemność.

Centrum obróbcze działa płynnie i bezproblemowo. Świetny wybór dla wymagających użytkowników.

Pracujemy na tej maszynie codziennie – precyzja i niezawodność na najwyższym poziomie.

Sterowanie Sinumerik 828 ułatwia pracę i zapewnia doskonałą powtarzalność.

Bardzo dobrze wykonana maszyna, zapewnia wysoką jakość obróbki.

MILL 1055 1000x550 z Sinumerik 828 to świetne centrum obróbcze – szybkie i dokładne.

CNC Machining Centre CORMAK MILL650 900x400 SIEMENS SINUMERIK

MILL 650 Machining Centre – Reliability and Precision for Demanding Professionals Our MILL 650 Machining Centre from the PREMIUM LINE series is the perfect solution for the most demanding professionals. Exceptional component quality from leading brands such as HIWIN, POSA, SIEMENS, FANUC, ...More

CNC Machining Centre CORMAK MILL530 900x400 SIEMENS SINUMERIK

Machining Centre MILL 530: Your Path to Precision Production The MILL 530 CNC machining centres are industrial machines delivering both reliability and precision. With their solid construction and proven components, these machines are ideal for demanding industrial applications. The rigid body ...More

CNC Machining Centre CORMAK MILL1470 1400×700 Siemens Sinumerik

Our machining centre combines solid construction with advanced technology, built on high-quality components ensuring long-term performance. Designed to efficiently perform milling, drilling, tapping and reaming operations, this machine is an indispensable tool in your production line. Its ability ...More

CMC Machining Centre CORMAK MILL540 650x400 SIEMENS SINUMERIK

MILL 540 Machining Centre: Your Path to Precision Manufacturing Our MILL 540 CNC Centres guarantee reliability and precision in one. With a robust construction and proven components, these machines are ideal for demanding industrial applications. The massive body ensures machining stability and ...More

CNC Machining Centre CORMAK MILL 2282 2200×820 SIEMENS SINUMERIK

Our machine combines innovative technologies with top-quality components, ensuring reliable performance over the long term. Designed for efficient execution of numerous operations such as milling, drilling, tapping and reaming, it is a key tool for productive manufacturing. With precision machining ...More

CNC Machining Centre CORMAK MILL1040 1000x400 SIEMENS SINUMERIK

Our MILL 1040 Machining Centre guarantees not only reliability but also the highest quality of machining. Using components from world-class manufacturers such as HIWIN, POSA, SIMENS, FANUC, OMRON, PRAGATTI, SHNAIDER, CHANDOX, FAG, BOSCH REXROTH , this machine offers virtually unlimited ...More

CNC Machining Centre CORMAK MILL850 1000x500 SIEMENS SINUMERIK

Our CNC Machining Centre MILL850 is the result of long-standing experience and engineering precision. Designed using proven components, these machines guarantee reliability and long-term performance. The massive frame ensures stability, allowing efficient and precise machining at every production ...More

CNC Machining Centre CORMAK MILL 1780 1700x800 SIEMENS SINUMERIK

The high-quality components used in the machine ensure reliable operation over a long period. The machine can efficiently perform multiple operations such as milling, drilling, tapping, and reaming while maintaining high machining precision. Each machine in this series is equipped with an efficient ...More

CNC Machining Centre CORMAK MILL500 5-Axis

5-AXIS MACHINING CENTRE MILL 500 The 5-axis version of the MILL 500 is a versatile and compact vertical machining centre designed for precise machining of complex components. The tilting rotary table with a diameter of 100 mm enables complete machining of a workpiece in a single setup, resulting ...More

CNC Machining Centre CORMAK MILL1570 1500×710 Siemens Sinumerik

The industrial machining centre MILL1570 is an advanced, precise and efficient CNC machine designed for demanding industrial applications. With a large working area of 1300×700 mm, it offers heavy-duty machining with excellent accuracy. Equipped with a counterbalanced spindle, linear guides and the ...More

copy of Machining Centre CORMAK MILL 400 800×240 SIEMENS SINUMERIK

The MILL 400 machining centre is an advanced vertical CNC machining centre designed for precision metalworking in industrial environments. Thanks to modern technologies, high-quality components and professional Siemens Sinumerik 808D control, the machine provides reliability, accuracy and ...More

CNC Machining Centre CORMAK MILL 400 5-Axis 800×240

5-axis CNC machining centre – a modern machine designed for precision machining of aluminium and other soft materials. With five-axis operation, it provides unrestricted access to the workpiece from every side, reducing machining time and eliminating multiple clamping. Ideal for manufacturing ...More

CNC Machining Centre CORMAK MILL640 700x400 SIEMENS SINUMERIK

MILL 640 Machining Centre: Innovative Efficiency for Your Production The MILL 640 CNC series has been designed using proven components to ensure exceptional performance and long-term reliability. The machine’s rigid body guarantees precise machining, while the sealed chamber ensures safety and ...More

CNC Machining Centre CORMAK MILL500 800x260 SIEMENS SINUMERIK

Machining Centre MILL 500: Excellence in Machining Precision Enter the world of precision and reliability with our MILL 500 CNC machining centres. Designed with proven components, these machines ensure not only efficient machining but also long-term dependability. The rigid body guarantees ...More

copy of CNC Machining Centre CORMAK MILL530 900x400 SIEMENS SINUMERIK

Machining Centre MILL 530: Your Path to Precision Production The MILL 530 CNC machining centres are industrial machines delivering both reliability and precision. With their solid construction and proven components, these machines are ideal for demanding industrial applications. The rigid body ...More

5-Axis CNC Machining Centre CORMAK MILL1200 Siemens Sinumerik

The 5-axis machining centre is ideal for producing precision components used in the aerospace, medical, automotive and other industries where exceptional accuracy and surface quality are required. By utilising advanced 5-axis technology, this machine increases production efficiency, reduces ...More

2024-09-10

Doskonała inwestycja

Maszyna warta swojej ceny – precyzyjna, szybka i bezawaryjna. Polecam!