- Reduced price

The basket is empty.

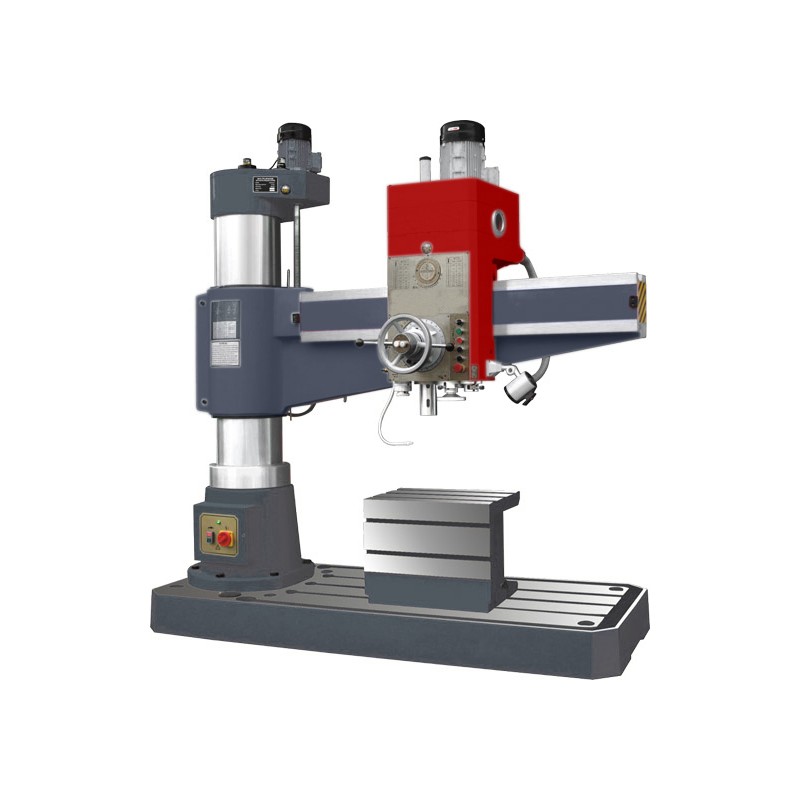

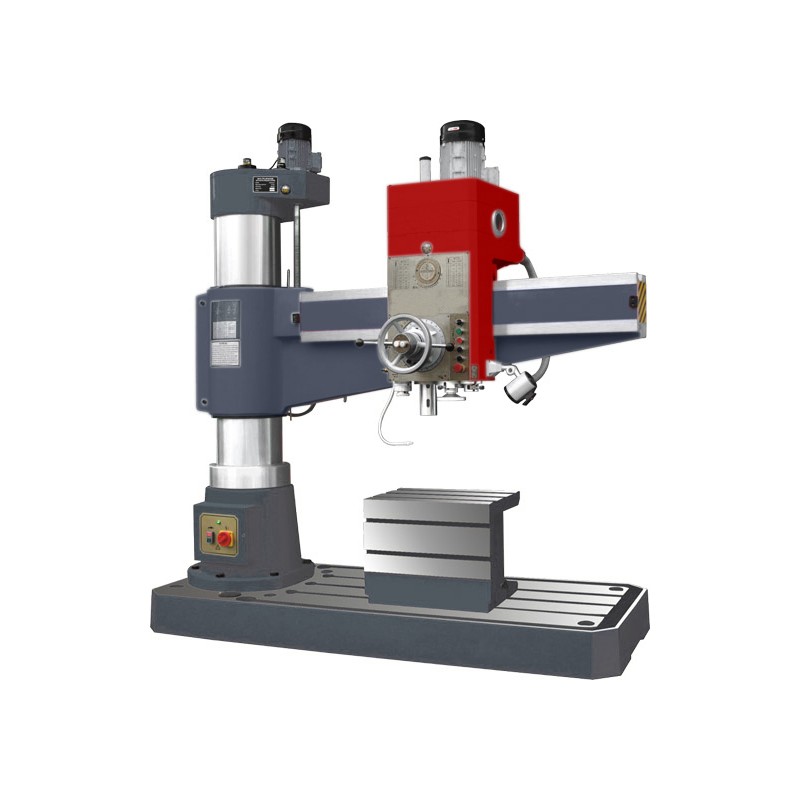

Industrial radial drilling machine with a solid and rigid structure ensuring high precision and reliability during hole machining. The device allows for drilling, reaming, counterboring, boring and tapping operations, performing effectively in a wide range of industrial applications.

Radial Drilling Machine CORMAK RD2500x80L is an advanced industrial machine designed for precision drilling in metal materials such as steel and cast iron. The unit features a massive column structure and a wide range of radial arm adjustments, ensuring high stability and flexibility when machining large workpieces. Its main advantage is the ability to drill holes up to 80 mm in diameter, making it a reliable tool for demanding production environments.

The CORMAK RD2500x80L radial drilling machine has been designed for heavy-duty industrial applications, offering reliability, precision and high performance. Its technical parameters, including a wide adjustment range and a powerful motor, allow efficient machining of large components without compromising quality. Below are the main benefits, directly derived from the construction and specifications of the machine, which distinguish this model among other radial drilling machines:

These features make the CORMAK RD2500x80L radial drill an indispensable solution for professionals demanding reliability and high performance in metal machining.

The CORMAK RD2500x80L radial drilling machine is based on a solid column structure, providing rigidity and resistance to heavy loads. The radial arm, adjustable from 500 to 2565 mm, allows precise positioning, while the lubrication system reduces wear and ensures long-term durability.

The manufacturing process includes precision grinding and hardening of key components, ensuring long-term reliability under industrial conditions.

The CORMAK RD2500x80L radial drilling machine achieves high precision thanks to its rigid construction and adjustable mechanisms. The spindle-to-table distance (500–1580 mm) and spindle-to-column distance (500–2565 mm) allow machining of large workpieces with micrometric tolerances. The wide range of speeds and feeds reduces downtime and boosts productivity.

Compared with smaller radial drilling models, this version offers greater machining capacity with its 7.5 kW motor and 400 mm spindle travel, allowing drilling up to 80 mm in diameter with minimal energy use. The cooling system reduces thermal deformation, ensuring repeatable precision in production batches.

The CORMAK RD2500x80L radial drill is designed for metalworking plants, mechanical workshops and maintenance departments. It excels in drilling large steel structures, machine components, moulds and parts for heavy industry, automotive and construction sectors. Its robust design makes it ideal for precision machining and intensive operation.

| Parameter | Value |

|---|---|

| Max drilling diameter | 80 mm |

| Spindle–column distance | 500–2565 mm |

| Spindle–table distance | 500–1580 mm |

| Spindle travel | 400 mm |

| Spindle taper | MT6 |

| Spindle speed range | (16) 16–1240 rpm |

| Spindle feed range | (16) 0.04–3.20 mm/rev |

| Table dimensions | 1000 × 800 mm |

| Horizontal head travel | 2000 mm |

| Spindle motor power | 7.5 kW |

| Machine weight | 9550 kg |

| Machine dimensions | 3510 × 1460 × 3290 mm |

Optimise your machining processes with the CORMAK RD2500x80L radial drilling machine. Contact us for detailed information, professional advice or to place an order – we guarantee fast delivery and expert support.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Cobalt Drill Bit Set CORMAK HSSE TiN 1–13mm 25pcs

The HSSE TiN cobalt drill bit set (1–13mm, 25 pieces) is a complete toolkit for drilling steel, cast iron and hard-to-machine materials. The TiN (titanium nitride) coating increases wear resistance and extends drill life. Ideal for workshops and industrial applications — ensuring precision and durability in everyday work. ...More

Tilting and Swivel Machine Vice CORMAK QHK100

The CORMAK QHK100 vice is made of high-grade cast iron. Its precise guidance makes this tilting and swivel machine vice ideal for precision engineering. The 360° swivel base allows horizontal rotation, while the 90° tilting cradle enables vertical adjustment. The hardened (55±3 HRC) and ground ...More

Tilting and Swivel Machine Vice CORMAK QHK125

The CORMAK QHK125 vice is made of high-grade cast iron. Its precise guiding system makes this tilting and swivel machine vice ideal for precision mechanics. The 360° swivel base allows horizontal rotation, and the 90° tilting cradle enables vertical adjustment. The tool-steel jaws are hardened ...More

Tilting and Swivel Machine Vice CORMAK QHK160

The CORMAK QHK160 vice is made of high-grade cast iron. Its precise guiding system makes this tilting and swivel machine vice ideal for precision engineering. The 360° swivel base enables full horizontal rotation, while the 90° tilt allows accurate vertical adjustment. Hardened (55±3 HRC) and ...More

Radial Drilling Machine for Metal CORMAK 3032x1000M

A drilling machine with a solid construction and high weight ensuring stability and vibration-free operation. Equipped with a cube table for easy alignment and secure clamping of the workpiece. Motor-driven arm height adjustment and front control panel provide convenience and work efficiency. The ...More

Radial Drilling Machine for Metal CORMAK 3032x1000

A drilling machine with a solid construction and high weight ensuring stability and quiet operation. The cube table allows precise positioning and clamping of the workpiece. With motor-driven arm height adjustment and a front-mounted control panel, operation is convenient and ergonomic. The ground ...More

Radial Drilling Machine for Metal CORMAK 3040x1300

A drilling machine with a solid construction and high weight ensuring stability and vibration-free operation. It features a cube table for easy positioning and clamping of the workpiece. Arm height adjustment is motor-driven, and the front control panel ensures convenient and efficient operation. ...More

Radial Drilling Machine for Metal CORMAK RD1600x50

A drilling machine with a solid, heavy construction ensuring stability and vibration-free operation. Equipped with a cube table for easy positioning and clamping of the workpiece. Motor-driven arm height adjustment and a front control panel enhance productivity and ergonomics. The ground column ...More

Write your review

* Required fields

I accept privacy policy rules