- On sale!

The basket is empty.

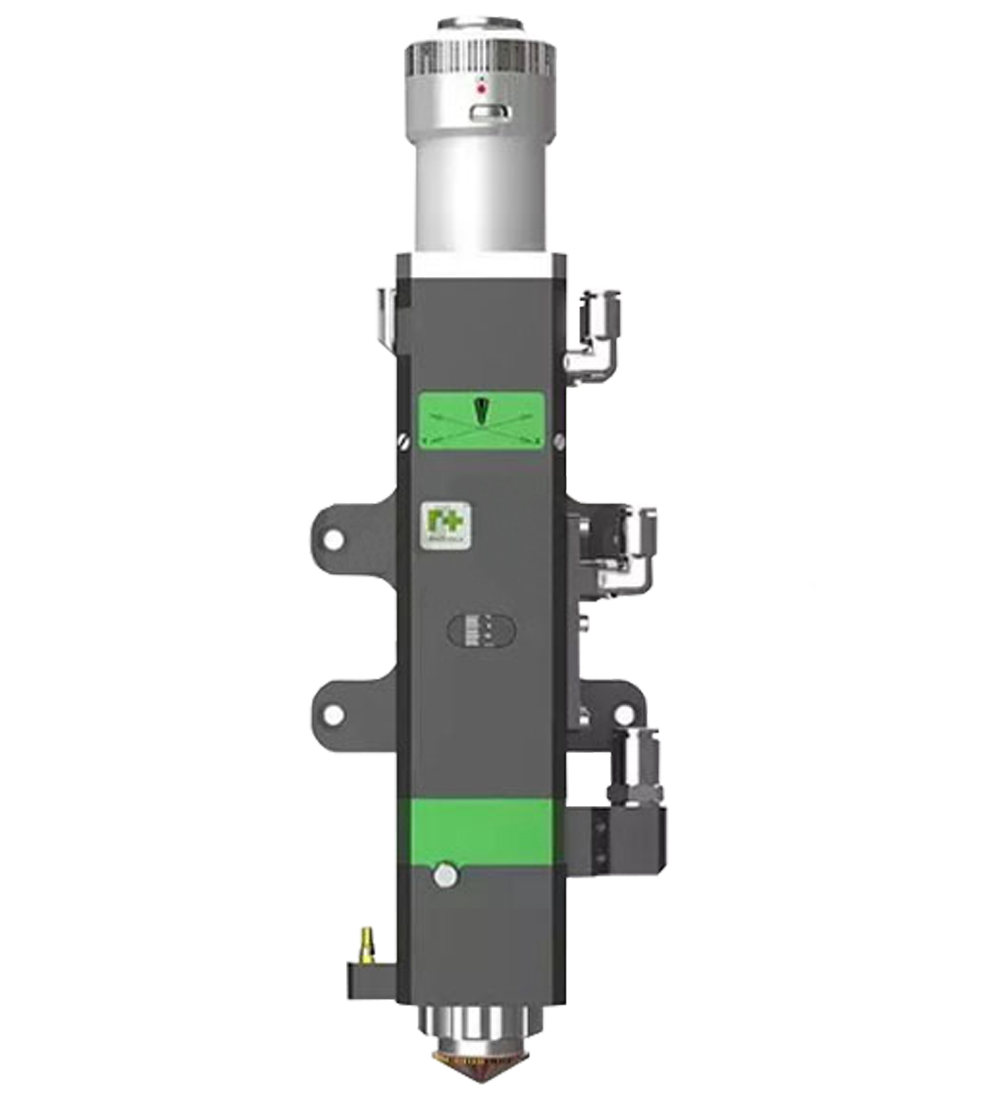

Advanced laser cutting machine for cutting sheet metal, tubes and profiles. Built with components from leading manufacturers for maximum reliability and durability. The solid, rigid frame minimises vibrations, ensuring exceptional cutting precision. The high-performance fibre laser features low operating costs and long, maintenance-free service life. An intuitive user interface and advanced software make it the perfect choice for companies aiming to increase productivity and efficiency.

Laser cutting machines are modern devices that stand out for their numerous advantages. They are not only an excellent and far more cost-effective alternative to CO2 technology, but also offer many benefits that can boost production by up to 70% and enhance quality. FIBRE technology enables cutting of sheets and other materials of various thicknesses — from very thin to very thick. The wavelength of the FIBRE laser is 1.064 micrometres, resulting in an intensity 100 times greater than that of CO2 systems of similar power.

MAIN ADVANTAGES OF THE LASER

Fibre laser

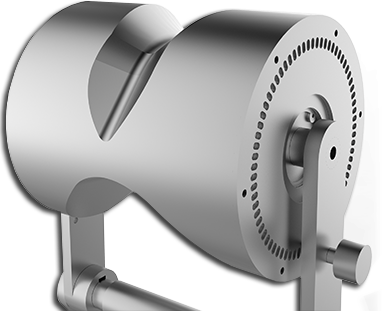

The LF3015EPR fibre laser cutting machine not only cuts sheet metal but also tubes and profiles. It offers multiple applications and saves over 50% of floor space, effectively increasing productivity.

The chuck grips the profile in two directions and automatically performs alignment. The diagonal adjustment range is 20–170 mm.

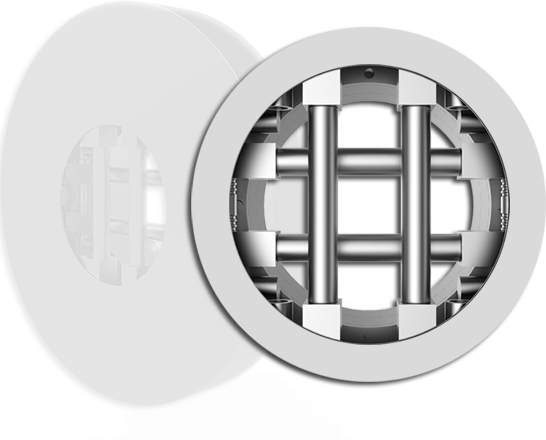

The bed structure features an internal honeycomb design made of welded rectangular tubes. Reinforcements inside the tubes improve the bed’s strength and rigidity, enhancing guide rail stability and preventing deformation. Its high strength and stability guarantee up to 20 years of use without distortion.

The intelligent tube support system effectively solves deformation problems occurring during the cutting of long pipes.

| WORKING AREA | 1500x3000 |

| POWER | 3000W |

| REPEATABLE POSITIONING ACCURACY | ±0.02 mm/m |

| MAXIMUM SPEED | 50 m/min |

| POWER SUPPLY | 400V 50Hz |

Actual parameters may vary depending on technical conditions and materials used.

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Fibre Laser Cutter for Tubes and Profiles CORMAK FIBER LF6035 1000W

The latest model of a fibre laser for cutting tubes and profiles , equipped with an automatic storage-feeding system for materials and a receiving storage for finished elements. The automation of the laser cutting process significantly improves work efficiency. Available laser powers: 1000W, ...More

Fibre Laser Cutter for Tubes and Profiles CORMAK FIBER LF6024 3000W

The latest model of the fibre laser for cutting tubes and profiles . Automation of the laser cutting process significantly increases work efficiency. The available laser power options include 1000W, 2000W, 3000W, 4000W, and 6000W. ...More

Fibre Laser Cutter with Tube and Profile Attachment CORMAK FIBER LF3015EPR 4000W 240mm Chuck

Advanced fibre laser cutting machine for cutting sheet metal, tubes and profiles. Built using components from leading global manufacturers to ensure exceptional reliability and long-lasting durability. The robust, welded frame minimises vibration, providing high cutting precision. The efficient ...More

Fibre Laser Cutter with Tube and Profile Attachment CORMAK FIBER LF3015EPR 6000W 170mm Chuck

Advanced fibre laser cutting machine for cutting sheet metal, tubes and profiles. Built with components from leading manufacturers to ensure maximum reliability and durability. The robust welded frame minimises vibrations, ensuring precision and consistent cutting quality. The high-performance ...More

Fibre Laser Cutter with Tube and Profile Attachment CORMAK FIBER LF3015EPR 6000W 350mm Chuck

Advanced fibre laser cutting machine for sheet metal, tube and profile cutting. Built with premium components from top manufacturers to ensure outstanding reliability and durability. The robust, reinforced bed minimises vibrations, guaranteeing high cutting precision and quality. The efficient ...More

Fibre Laser Cutter for Tubes and Profiles CORMAK FIBER LF60240A with Automatic Feeder

The latest model of the fibre laser for cutting tubes and profiles, equipped with an automatic storage-feeding system and a receiving magazine for finished components. The automation of the laser cutting process significantly improves work efficiency. The available laser power options include ...More

Write your review

* Required fields

I accept privacy policy rules