Fibre laser cutting machines are modern devices offering numerous advantages. They are not only an excellent and far more economical alternative to CO2 technology, but also feature many benefits that enable production growth (up to 70%) and improved quality. FIBER technology allows cutting of sheets and other materials of various thicknesses, from very thin to very thick. The wavelength in a FIBER laser is 1.064 micrometres, resulting in an intensity 100 times greater than that of CO2 machines of similar power.

Main advantages of the laser:

- maintenance-free fibre source,

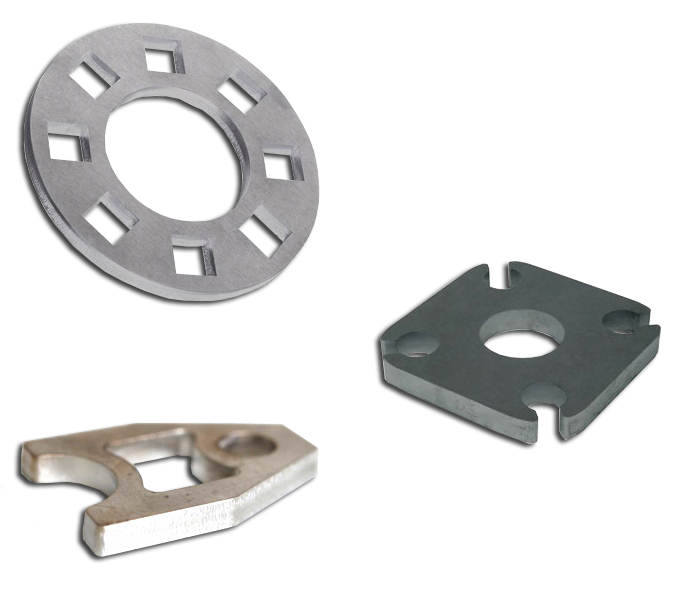

- no consumable parts,

- the fibre laser source requires about one-third less space,

- high energy efficiency – 100,000 h of operation,

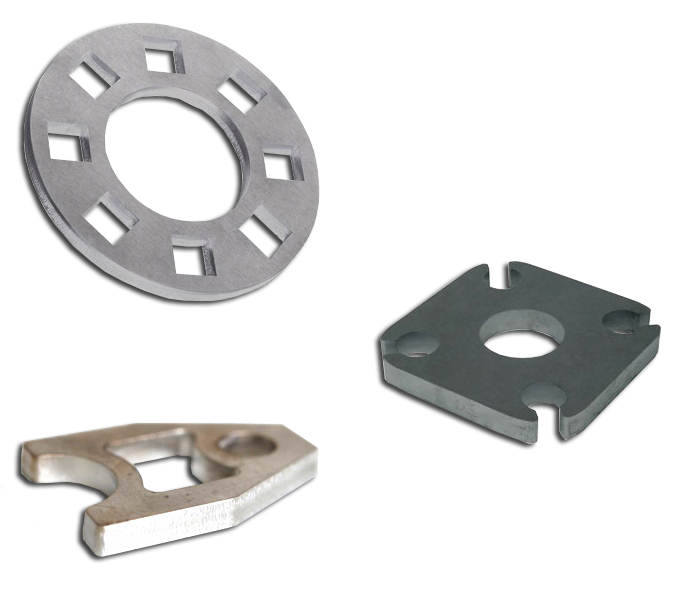

- universal application (special steels, mild and stainless steel, copper, brass, aluminium, titanium).

Fibre laser

- increases productivity by 80%,

- reduces service costs by 70%,

- saves 80% energy,

- minimises gas consumption,

- saves 30% of workshop space.

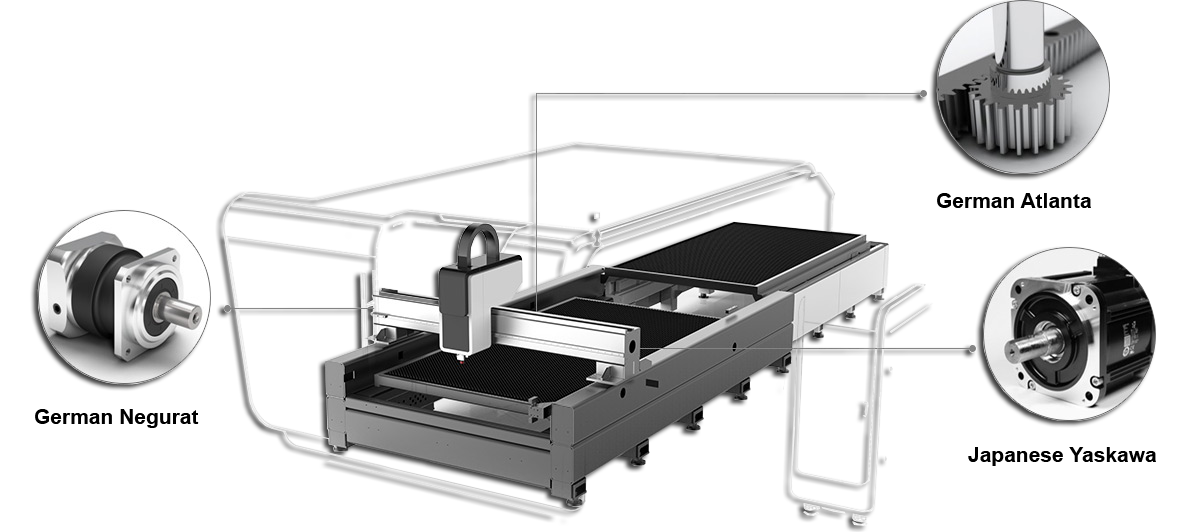

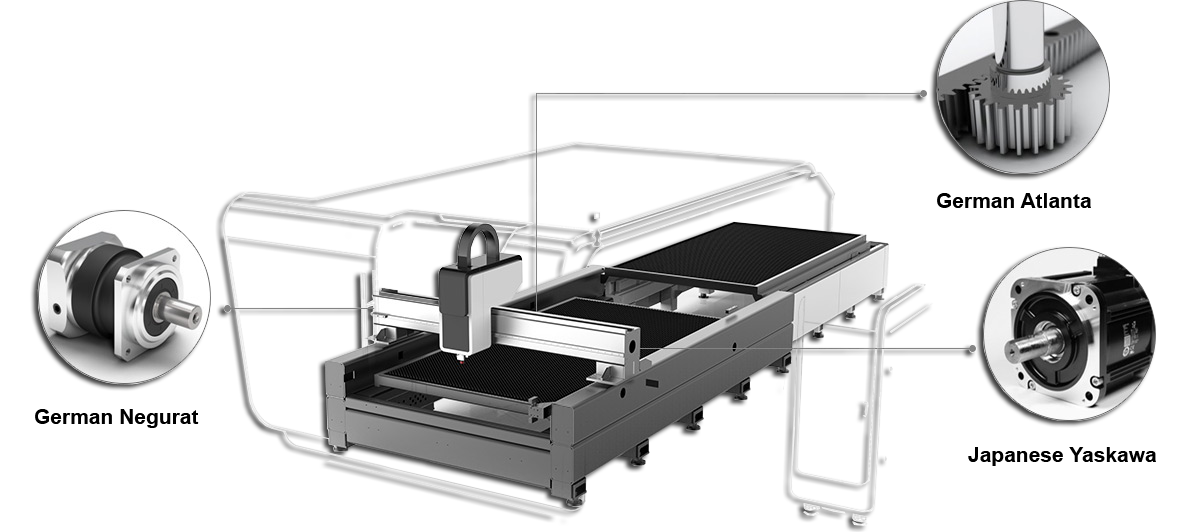

Sliding gantry made of aged aerospace aluminium

The sliding gantry is made of aged aerospace aluminium formed under a 4,300-ton pressure, achieving exceptional rigidity. Aerospace aluminium provides high stiffness (greater than cast iron), low weight, corrosion and oxidation resistance, and excellent machinability.

Safety and clean operation

- fully enclosed laser housing,

- observation window with CE-certified protective glass,

- fumes generated during cutting can be filtered internally, keeping the environment clean.

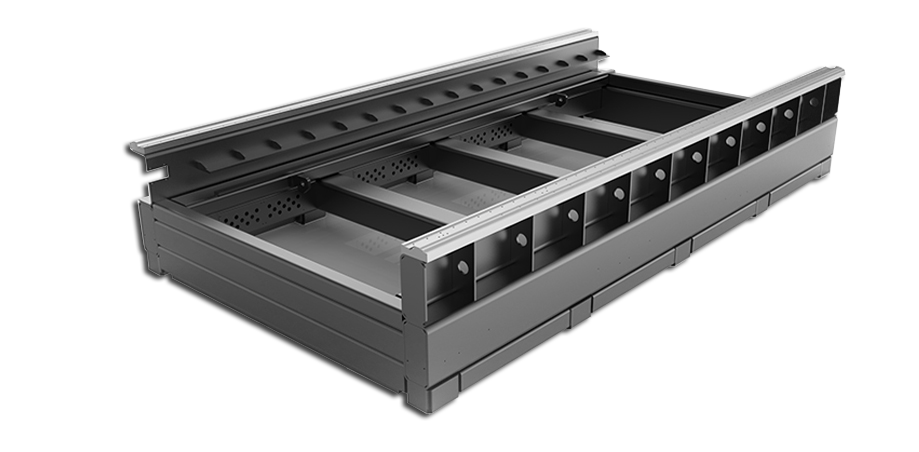

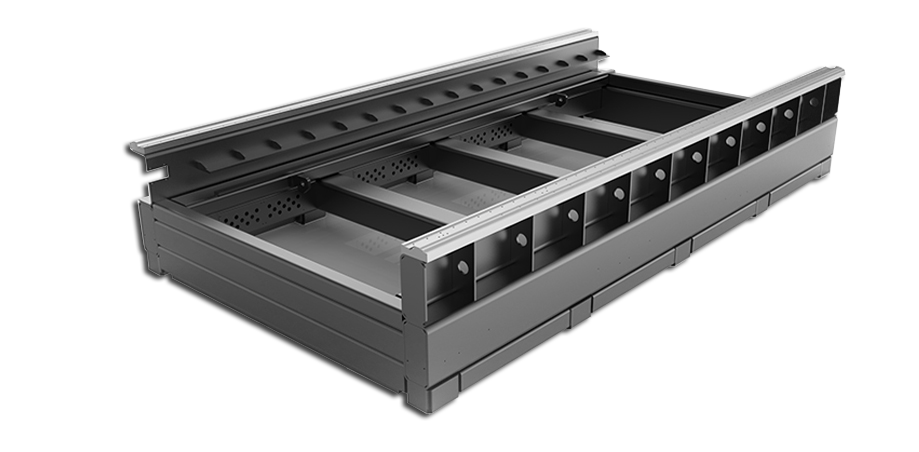

Welded bed made of rectangular profiles

The bed structure features an internal honeycomb design made of numerous welded rectangular tubes. Reinforcements inside the tubes increase the strength and rigidity of the bed, improving guide rail stability and preventing deformation. High strength, stability and tensile resistance ensure up to 20 years of distortion-free operation.

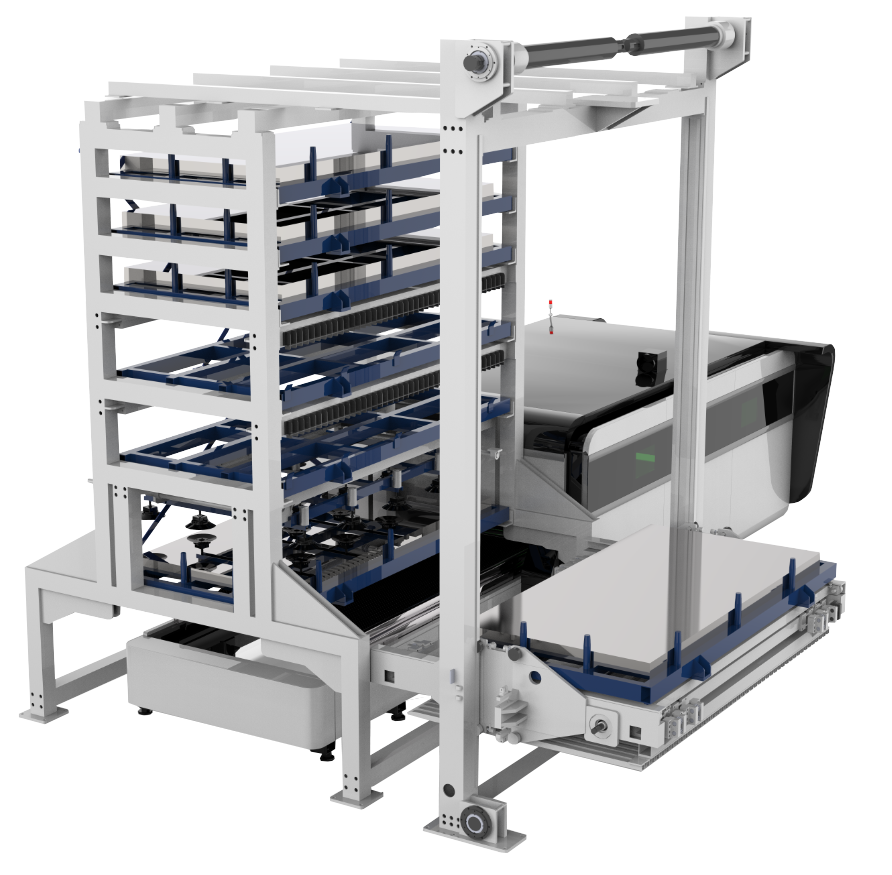

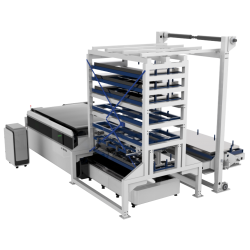

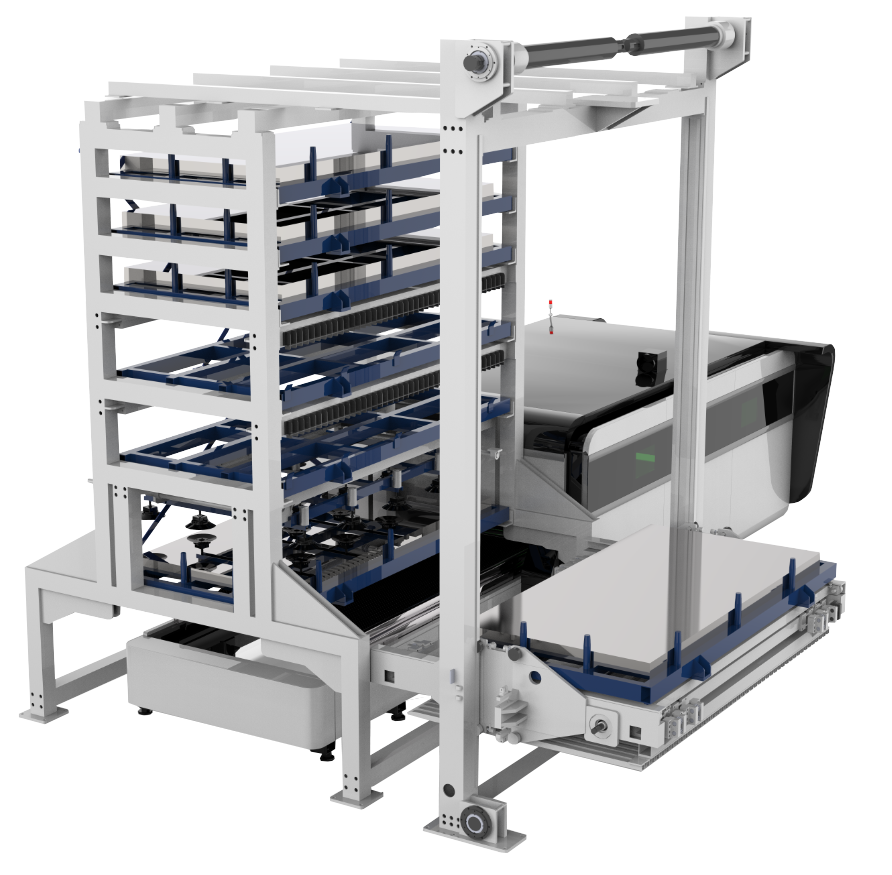

Automatic material storage system

The six-level material storage system automatically stores and sorts materials, significantly reducing labour costs. The storage unit consists of three levels: cache level (1 platform), raw material level (3 platforms), and finished product level (2 platforms).

Monitoring

A high-resolution camera allows process monitoring without interrupting cutting or opening the machine, significantly improving safety and work efficiency.

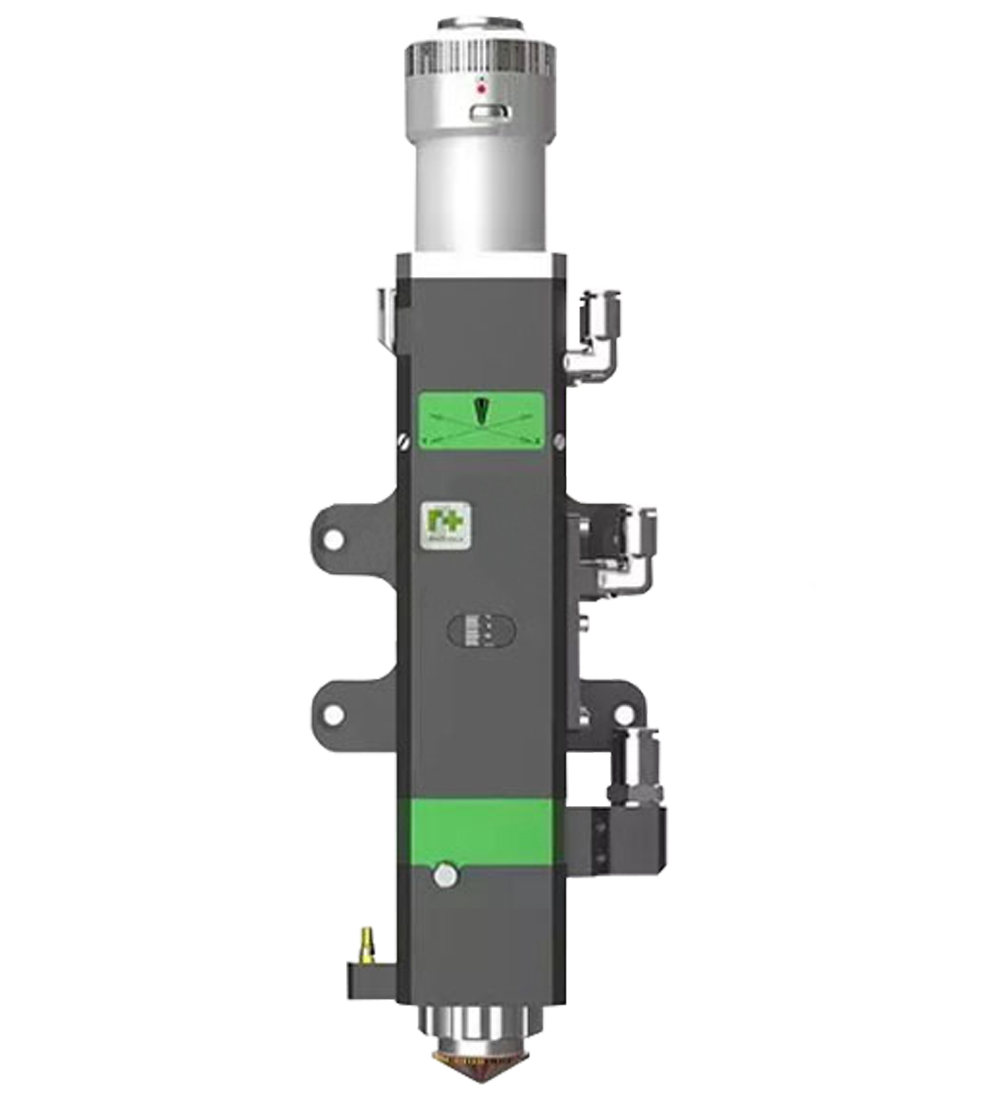

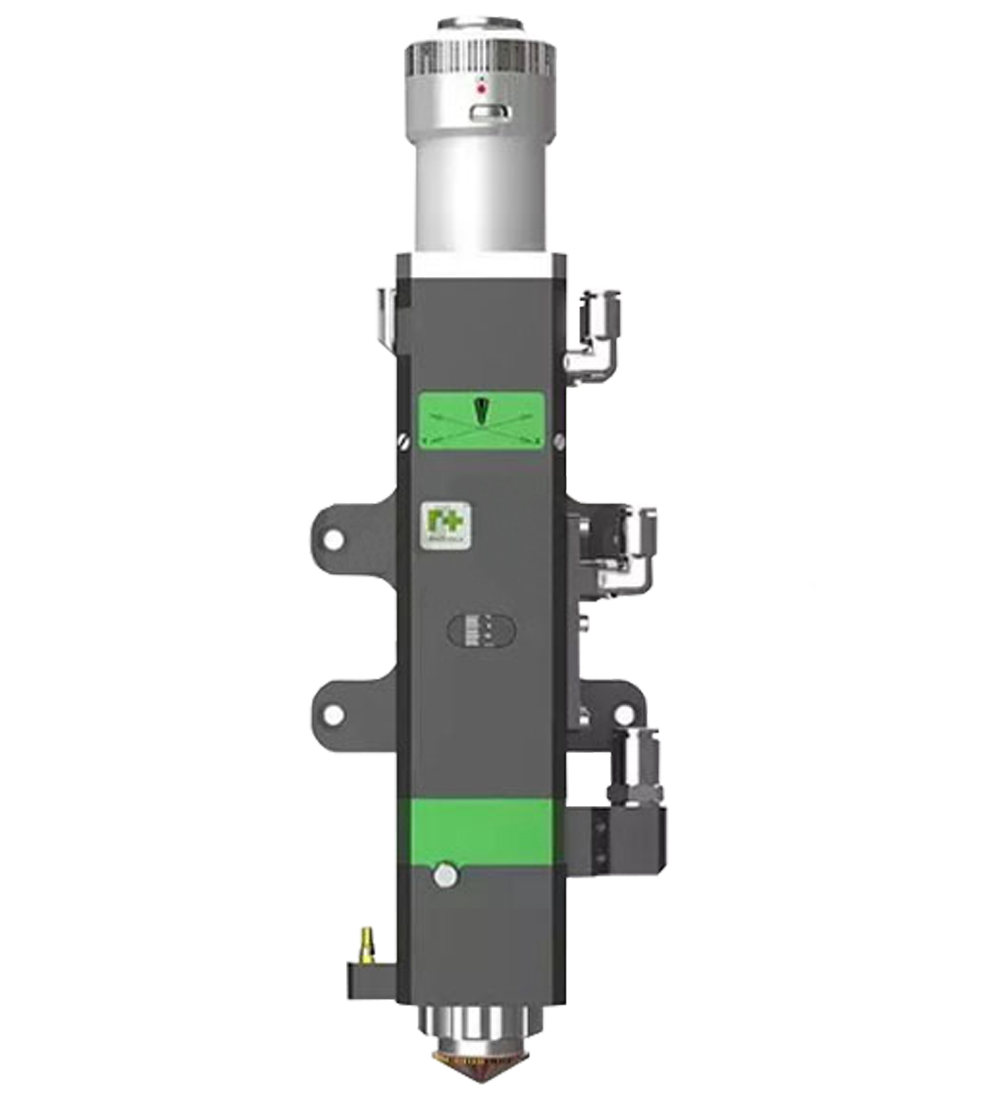

Raytools cutting head

- Automatic focus adjustment – Autofocus – The software automatically adjusts the focusing lens when cutting sheets of different thicknesses. The autofocus speed is ten times faster than manual adjustment.

- Wider manual adjustment range – Adjustment range −10mm to +10mm with 0.01mm precision, suitable for different material thicknesses (0–20mm) below 1500W.

- Long service life. Collimator and focusing lenses are water-cooled, reducing head temperature and extending cutting head lifespan.

Technical parameters

| WORKING AREA |

1500x3000 |

| POWER |

1000W–12000W |

| REPEATABLE POSITIONING ACCURACY |

±0.02 mm/m |

| MAXIMUM SPEED |

120 m/min |

| MAXIMUM ACCELERATION |

1.5G |

| MAXIMUM PLATFORM LOAD |

3 tonnes |

| MAXIMUM SHEET HEIGHT |

100 mm |

| POWER SUPPLY |

400V 50Hz |

Cutting parameters

Actual cutting parameters may vary depending on technical conditions and materials used.

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.

Write your review

* Required fields

I accept privacy policy rules