LASER CUTTING PROCESS

Laser cutting is a modern and widely used material processing technique. The cutting tool in this method is a high-energy-density laser beam that cuts through the material.

Laser cutting process sequence

The laser cutting process is based on the interaction of the laser beam at its focal point, where its power is the highest, causing rapid melting, evaporation, ablation and heating of the cut material to ignition temperature. The area where the beam hits the material is flushed with a fast-flowing gas that removes the molten material along the beam axis.

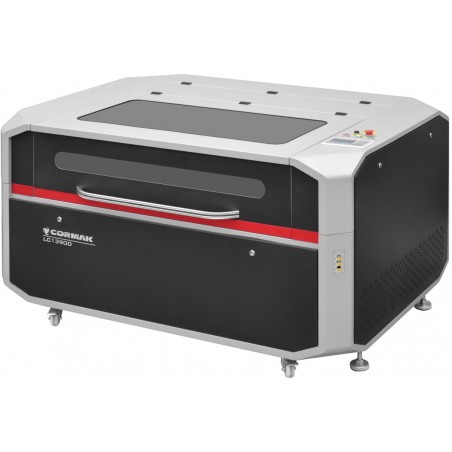

| MACHINE DIMENSIONS |

1900 x 1500 x 1020 mm |

| LASER TYPE |

CO2 |

| MAXIMUM LASER POWER |

160W (option*: 80W, 100W, 130W, 180W) |

| MACHINE WEIGHT |

400 kg |

| MAXIMUM WORKING AREA |

1300 x any / any x 900 mm |

| POSITIONING ACCURACY |

± 0.01 mm |

| MECHANICAL RESOLUTION |

0.0254 mm |

| MAXIMUM POWER CONSUMPTION |

1000W |

| OPERATING TEMPERATURE |

15 – 45 ℃ |

| Operating system |

Windows 95, 98, 2000, XP, Vista, 7, 8, 10 (32/64 bit) |

| Input file formats |

PLT, AI, DST, DXF, BMP |

| Compatible software |

CorelDraw AutoCAD Photoshop |

| Drive type |

Stepper motors |

| Communication |

USB |

| Tube cooling |

CW5200 chiller |

| Material cooling |

air |

Write your review

* Required fields

I accept privacy policy rules