CORMAK SG1000RP – universal machine for deburring and edge rounding

The SG1000R is a versatile and innovative solution that ensures excellent results in processing punched and laser-cut parts. It is ideal for burr removal, edge rounding and optional surface finishing on customer request.

Complete processing in a single pass

The SG1000R is as flexible as a laser. In one working cycle:

- Abrasive belt removes burrs left after cutting.

- Unique rotor provides precise and uniform edge rounding, allowing a radius of up to 2.0 mm.

- Optional finishing module (option*) ensures a visually flawless surface.

Thanks to the vacuum table, the SG1000RP allows machining of both large flat components and small sheet metal details.

Versatile applications

The SG1000RP handles every challenge:

- Processing of perforated components with surface finishing.

- Precise rounding of laser-cut edges with up to 2.0 mm radius.

- Machining both small parts and large sheet elements.

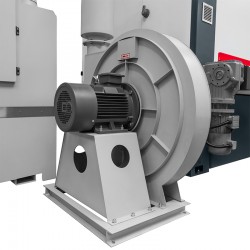

Perfect results through advanced design

The machine is equipped with three main working units:

- Wide belt unit with sanding belt for deburring.

- Rotating brushes for edge rounding.

- Vacuum table

- Water-based filtration and ventilation system.

The heart of the machine is an innovative rotor that acts evenly on all sides of the sheet edges, guaranteeing extremely precise rounding.

The set includes a vacuum generator and a water filtration-ventilation system.

Intuitive operation and full process control

The advanced control module automatically adjusts settings to the workpiece parameters, optimising the process and ensuring consistent results. The system monitors brush wear and compensates for it in the machine settings.

Why choose the SG1000RP?

- Best possible edge rounding results.

- Excellent performance and precision.

- Wide range of applications – from small parts to large sheet components.

- Optional surface polishing on request (option*).

The SG1000RP is the most versatile deburring and edge-rounding machine in the CORMAK range – indispensable in workshops demanding top-quality component finishing. Choose perfection and flexibility!

Technical data

| Max. working width |

1000 mm |

| Working thickness |

0 - 80 mm |

| Minimum workpiece size |

50 x 50 mm |

| Feed speed |

1–5 m/min |

| Belt head: |

|

| Roller diameter |

130 mm |

| Belt size |

1030 × 1900 mm |

| Main motor |

36 kW |

| Planetary head: |

|

| Abrasive drum size |

Ø300 × 295 mm, bore 32 mm |

| Brush drive motors |

2 × 2.2 kW, 30–1300 rpm |

| Planetary rotation motor |

5.5 kW, 1–17 rpm |

| Extraction port diameter |

200 mm |

| Operating temperature / humidity |

+5 – +40°C, 5–85% |

| Noise level |

approx. 80 dB |

| Power supply |

400 V |

| Weight |

2550 kg |

| Machine dimensions |

2570 × 1620 × 1980 mm |

*The price quoted is for the machine itself, excluding optional/additional equipment, installation, transport and training— please contact our consultant for more details.

Write your review

* Required fields

I accept privacy policy rules