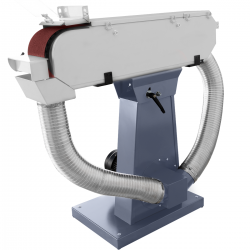

Belt Grinder for Metal CORMAK BS150-200 with Dust Extraction – powerful, clean, and precise operation

The CORMAK BS150-200 belt grinder is an industrial-grade machine designed for intensive use in production plants, locksmith workshops, and toolrooms. This metal belt grinder combines high grinding performance with an efficient dust extraction system, ensuring safety, cleanliness, and comfort during daily operation. The robust steel construction and large worktable provide stability and precision even when processing large workpieces.

Main advantages of the machine

- Two belt speeds (15 / 30 m/s) – enables adjustment of speed to the material type and operation (rough or finishing grinding).

- Integrated dust extraction system – provides a clean and safe working environment without the need for external extraction units.

- Stable steel construction – effectively reduces vibrations, ensuring repeatability and machining quality.

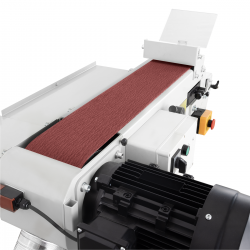

- Large worktable (480 × 150 mm) – allows comfortable handling of larger components.

- Stepless grinding angle adjustment – allows precise positioning of the belt to the workpiece.

- Quick belt change system – minimises downtime and improves work efficiency.

Design and technology

The stationary grinder CORMAK BS150-200 is built on a welded steel frame ensuring rigidity and resistance to dynamic loads. The integrated extraction system with a 0.37 kW motor and two Ø100 mm nozzles guarantees high dust and grinding chip removal efficiency. The main 3.0 kW motor provides sufficient power for the most demanding machining tasks.

Precision and performance

With a belt width of 150 mm and length of 2000 mm, the machine offers a large contact area, shortening processing time and increasing efficiency. Two working speeds allow quick switching between rough grinding and fine finishing. The ergonomic design and spring belt tensioning system maintain correct tension throughout the working cycle.

Applications

The CORMAK BS150-200 belt grinder for metal is suitable for:

- production facilities processing steel, stainless steel, and aluminium,

- welding and locksmith workshops,

- surface preparation and finishing areas,

- edge, weld, and flat surface grinding.

Standard equipment

- Stable steel base with tilt adjustment

- Abrasive belt 2000 × 150 mm

- Built-in extraction system with bag and Ø100 mm connectors

- Anti-spark and dust protection cover

- Tilting protective shield

Technical data

| Abrasive belt dimensions (L × W) |

2000 × 150 mm |

| Belt speed |

15 / 30 m/s |

| Motor speed |

1400 / 2800 rpm |

| Main motor power |

3.0 kW |

| Extraction motor power |

0.37 kW |

| Extraction efficiency |

– |

| Dimensions (L × W × H) |

1000 × 650 × 1150 mm |

| Weight |

117 kg |

| Power supply |

400 V |

| Extraction nozzle diameter |

2 × Ø100 mm |

| Worktable size |

480 × 150 mm |

| Chip bag diameter |

Ø 320 mm |

| Chip bag length |

650 mm |

Choose quality, precision, and cleanliness in your workplace – select the CORMAK BS150-200 belt grinder and ensure the highest machining standard for your workshop.