Main Advantages – Why Choose the CORMAK HBS421 Wood Band Saw

- High cutting system stability – reduced vibration for cleaner cuts and longer blade life.

- Wide cutting range – comfortable work with large components (panels, beams, structural elements).

- Precision work table – provides secure material support and maintains the cutting angle throughout the cut.

- Controlled blade tension – stable blade tracking improves straightness and minimises deviation.

- Adjustable blade speed – optimised performance depending on wood type, section and cut direction (longitudinal/cross).

- Clean operation features – extraction port for connection to dust collection systems.

Design and Technology – Advanced Technical Construction

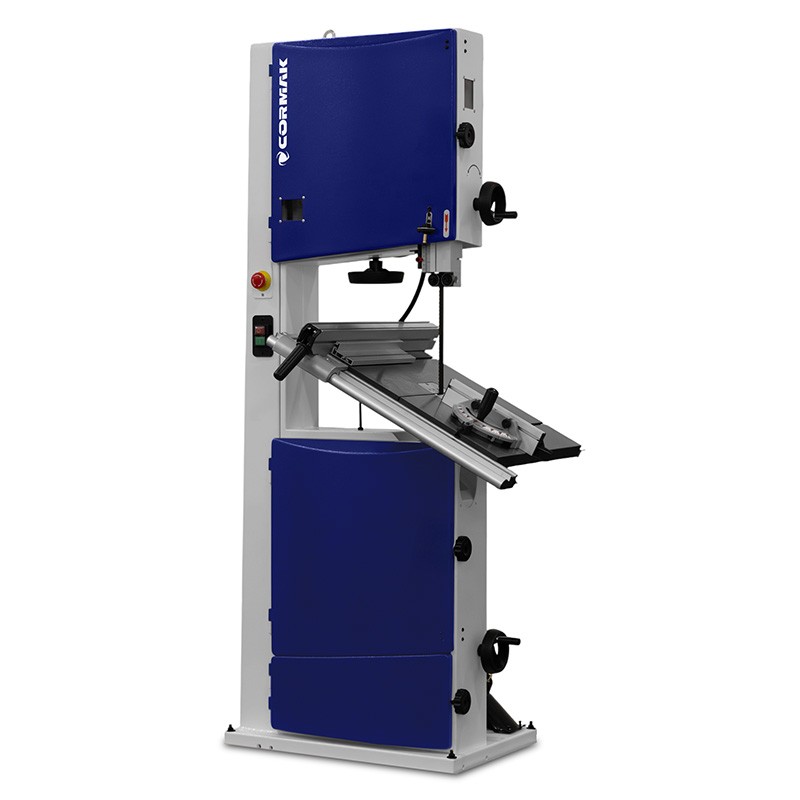

The CORMAK HBS421 wood band saw is designed as a vertical system for comfortable material handling and precise straight or curved cuts. In production use, rigidity is crucial – the frame and structural components ensure perfect wheel alignment and stable blade tracking for consistent results.

Drive Wheels and Blade Guidance

In professional band saws, cutting accuracy depends on precise geometry. Properly designed drive wheels ensure stable blade movement, reduce slip and eliminate local stress. This results in:

- less vibration at higher feed rates,

- better edge quality – especially when cutting hardwoods,

- extended blade life thanks to smooth and stable operation.

Work Table and Angle Adjustment

The work table supports the material and ensures repeatable cutting accuracy. In the CORMAK HBS421 wood band saw, both stability and adjustability are key — allowing quick switching between straight and angled cuts. This makes it ideal for carpentry shops that require fast, versatile production workflows.

Drive System and Continuous Operation

The drive system is designed for continuous load operation, while the three-phase power supply ensures smooth performance and stable torque. As a result, the vertical wood band saw maintains cutting precision even in thicker materials, which is essential for serial production. Adjustable blade speed allows optimisation for each job, preventing edge burning and improving cut control.

Dust Extraction and Workplace Ergonomics

Wood cutting produces significant amounts of dust and chips. The integrated extraction port allows connection to a dust collection system, which effectively improves:

- operator safety (reduced airborne dust),

- cutting line visibility,

- service life of components by reducing dust accumulation.

Precision and Work Efficiency

In industrial applications, not only cutting ability but also repeatability matters. The rigid frame, stable blade tracking and controlled tension ensure straight, clean cuts and reduce rework at later processing stages (planing, sanding, fitting). The CORMAK vertical wood band saw shortens cycle times and minimises material waste.

Applications

The CORMAK HBS421 band saw is intended for professional woodworking and wood-based material processing, especially in:

- carpentry and furniture workshops,

- wooden structure component production,

- format cutting and trimming for further processing,

- workshop operations requiring precise straight or curved cutting.

Standard Equipment

- ON/OFF switch with high-voltage trigger

- Dust extraction port 2×100 mm

- Precision fence

- Saw blade 3345×20 mm, 8 TPI

Optional Equipment

- 100 mm extraction hose

- Galvanised clamp

- Mobile base up to 260 kg

Technical Data

| Wheel diameter [mm] |

480 |

| Maximum cutting height [mm] |

240 |

| Maximum cutting width [mm] |

405 |

| Blade width [mm] |

9.5 – 38.1 |

| Blade length [mm] |

3345 |

| Blade speed [m/s] |

7 / 14 |

| Table tilt range [°] |

0 to +45 |

| Table dimensions [mm] |

535 × 435 |

| Overall dimensions [mm] |

830 × 550 × 2070 |

| Weight [kg] |

160 |

| Motor power |

S1 – 2.2 kW / S6 – 3.1 kW |

| Power supply |

3-phase, 400 V |

| User manual |

yes |

| CE Declaration |

yes |

Need a high-performance band saw for production work? Choose the CORMAK HBS421 vertical wood band saw and tailor the configuration to your workshop needs. Contact us for an offer, availability and blade recommendations for your specific applications.