The basket is empty.

Invest in modernity and versatility with the ZX7055 DRO milling and drilling machine, ideal for small and medium-sized maintenance or production departments. This medium-sized machine offers not only automatic feed with a vertical head but also threading functions and a digital readout as standard. Discover its reliable features that make the ZX7055V DRO an excellent choice for your workshop:

Drilling–Milling Machine CORMAK ZX7055 VARIO DRO by CORMAK is an efficient universal milling machine designed for drilling, milling and tapping in steel and cast iron. Built on a solid cast-iron frame with smoothly adjustable speeds in two ranges and a digital readout system, it ensures repeatable accuracy in both unit and small-batch production.

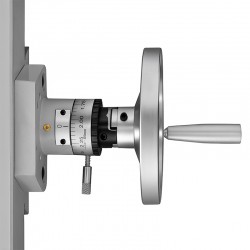

The machine’s core is a heavy cast-iron body with wide guides that minimise deflection during face and end milling. The massive cross table with a precision-ground surface guarantees perfect flatness for workpiece positioning. The MK4 spindle taper is driven by a 1.5/1.8kW S1/S6 motor with smooth speed adjustment. The integrated cooling system stabilises cutting zone temperature and improves surface finish quality.

The combination of the 2-axis DRO, ground gears and solid guides ensures high dimensional repeatability and surface smoothness. The automatic spindle feed and two speed ranges allow stable cutting parameters for drilling up to Ø32mm in steel and Ø45mm in cast iron, as well as face milling up to Ø80mm and end milling up to Ø28mm. The ergonomic head height adjustment shortens setup time for both serial and single-piece work.

The ZX7055 VARIO DRO is recommended for toolrooms, maintenance departments, locksmith workshops and small-batch production where a multi-purpose drilling–milling machine is required, combining drilling, milling, countersinking and tapping in one unit.

Heavy, stable cast-iron frame: The solid cast structure ensures durability and precision. The ZX7055V DRO maintains stability even under heavy-duty tasks.

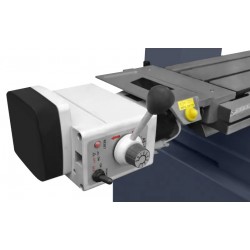

Automatic spindle feed: Save time and increase productivity with automatic feeding. The vertical head allows efficient machining without constant supervision.

Massive cross table with precision-ground surface: Guarantees perfect flatness and accuracy during machining.

Dovetail guides: Ensure smooth and precise three-axis movement for top machining results.

Quiet operation thanks to ground gears: Focus on work, not on noise. Ground gears guarantee quiet operation and comfort.

Left/right rotation: Adapt the machine to your needs. Dual-direction spindle rotation increases machining flexibility.

Tilting head ±90° and adjustable height: Perfect for angled and multi-position operations.

The ZX7055V DRO drilling–milling machine is a modern tool that will redefine your machining experience. Order today and experience exceptional performance in your workshop!

The machine base is available as an optional accessory.

| Technical parameters: | |||

| Maximum drilling capacity | Cast iron (HT200) | 45mm | |

| Steel | 32mm | ||

| Maximum face milling | 80mm | ||

| Maximum end milling | 28mm | ||

| Table size | 820×240mm | ||

| Table travel (X/Y) | 595 / 185mm | ||

| Maximum tapping capacity | M24 | ||

| Spindle taper | MK4 | ||

| Spindle speed (rpm) | Motor S1/S6 1.5/1.8kW | Low: 75–438 / High: 438–2500 | |

| Spindle travel | Manual: 107mm / Automatic: 100mm | ||

| Distance spindle–column | 250mm | ||

| Max. distance spindle–table | 445mm | ||

| Net weight | 350kg | ||

| Overall dimensions | 1084×924×1550mm / with base 2150mm | ||

Contact a CORMAK advisor. Add ZX7055 VARIO DRO to your basket or send an enquiry – we will prepare a configuration tailored to your technology.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Universal Multi-Purpose Milling Machine CORMAK MFM230

We present the CORMAK MFM230 Universal Multi-Purpose Milling Machine – a versatile tool that takes metal machining to a new level. With a head tilting on two axes, offering a right/left tilt of ±90° and a front/back tilt of ±45°, this innovative machine provides advanced technological ...More

ZX7045B1 DRO Milling and Drilling Machine

This machine can be used for drilling, reaming and boring holes up to 45/40 mm in cast iron, threading up to M12 mm bolts, up to 80 mm milling and up to 22 mm notching. It is also useful for cutting and frontal milling. ZX 7045 B1 DRO is by default equipped with an autofed spindle, digital display and a cooling system. ...More

Drilling–Milling Machine CORMAK ZX40BPC

The CORMAK ZX40BPC is a robust drilling–milling machine for metalworking. Its head can swivel ±90°, and the spindle offers the same angular adjustment. The machine features automatic spindle feed, left and right spindle rotation, a large working table, coolant system, and optional automatic table ...More

Drilling–Milling Machine CORMAK ZX50BPC

The CORMAK ZX50BPC is a robust drilling–milling machine for metalworking. The head and spindle can swivel ±90°, and the machine is equipped with automatic spindle feed, right and left spindle rotation, a large working table, and a coolant system. An optional automatic table feed in the X axis is ...More

Drilling–Milling Machine CORMAK ZX7045

The CORMAK ZX7045 drilling–milling machine is designed for drilling, reaming, and enlarging holes up to 45/40 mm in cast iron, as well as for thread cutting up to M12 mm, face milling up to 80 mm, and slot milling up to 22 mm. It is also suitable for cutting and face milling operations. The machine is available directly from stock. ...More

Drilling–Milling Machine CORMAK ZX7045E DRO

The CORMAK ZX7045E DRO drilling–milling machine with digital readout is a versatile and precise tool for metalworking. It performs drilling, boring, threading, and both face and peripheral milling operations. Suitable for holes in cast iron up to Ø45/40 mm, threads up to M12, and grooves up to 22 ...More

Drilling–Milling Machine CORMAK ZX7550 ZB

The XZ7550ZB Drilling–Milling Machine is a reliable and efficient tool designed for professional metalworking. This robust, straightforward machine guarantees continuous operation over long periods. Equipped with both a vertical head and a horizontal spindle, the XZ7550ZB offers broad machining ...More

Drilling–Milling Machine CORMAK ZX7045E 230V

The CORMAK ZX7045E milling and drilling machine is a versatile tool for metalworking. It performs drilling, reaming, boring, threading, and both peripheral and face milling operations. Designed for precision, it drills holes in cast iron up to Ø45/40 mm, mills up to 80 mm wide, and cuts grooves up ...More

Universal Milling Machine CORMAK XL6336L SERVO

The Universal Milling Machine XL6336L SERVO is a robustly built machine designed for machining heavy workpieces. Its rigid construction ensures stability during demanding operations, while the large worktable enables efficient processing of large components. With the ability to work both as a ...More

Universal Multi-Purpose Milling Machine CORMAK MFM380

The CORMAK MFM380 Universal Multi-Purpose Milling Machine features a swivelling head in three axes. The machine offers extensive technological capabilities, making it suitable for both single-piece and serial production. It is equipped with stepless spindle speed control, hardened guideways and a ...More

Drilling–Milling Machine CORMAK XZ 6350ZB

Our CORMAK XZ 6350ZB Drilling–Milling Machine guarantees reliability and precision in one unit. Featuring a simple, durable construction, this machine ensures uninterrupted operation for years. Equipped with both horizontal and vertical spindles, the XZ 6350ZB offers maximum versatility. The ISO 40 ...More

Drilling–Milling Machine CORMAK ZX7032G 400 V

This machine can be used for drilling, reaming and enlarging holes up to 32 mm in cast iron, as well as tapping holes up to M12, milling up to a width of 80 mm and slotting up to 22 mm. It is also suitable for cutting and face milling operations. ...More

Universal Multi-Purpose Milling Machine CORMAK MFM320

The CORMAK MFM320 Universal Multi-Purpose Milling Machine features a swivelling head in three axes. This machine offers extensive technological capabilities, making it suitable for both single-piece and serial production. It is equipped with stepless spindle speed adjustment, hardened guideways and ...More

Drilling–Milling Machine CORMAK HK25L VARIO with Power Feed

Invest in the CORMAK HK25L VARIO to experience not only robust build quality but also outstanding flexibility in completing a wide range of machining tasks. This drilling–milling machine is an essential tool for anyone who values efficiency, precision, and versatility. Discover new possibilities in ...More

Universal Multi-Purpose Milling Machine CORMAK MFM250

Our CORMAK MFM250 Universal Multi-Purpose Milling Machine is a versatile tool that revolutionises metal machining. With a head tilting on two axes, allowing a right/left tilt of ±90° and a front/back tilt of ±45°, this machine performs precise and complex milling operations. Featuring three ...More

Universal Multi-Purpose Milling Machine CORMAK MFM300

The CORMAK MFM300 Universal Multi-Purpose Milling Machine is an excellent solution for companies specialising in metal machining. With a head tilting on two axes, offering a right/left tilt of ±90° and a front/back tilt of ±45°, this machine performs complex milling operations with the highest ...More