The basket is empty.

Surface grinder for continuous production work, a large grinding range and SIEMENS PLC programmable controller. Features a modern, stable structure. The spindle head operates on two pairs of guides. Automatic feeds for 3 axes, digital readout included as standard.

Surface Grinding Machine 300x1000 - CORMAK

The Surface Grinding Machine 300x1000 is an advanced unit dedicated to precise grinding of flat surfaces in industrial settings. Equipped with automatic feeds for three axes and a 300x1000 mm magnetic table, it offers exceptional accuracy and reliability. Its solid construction and ability to handle loads up to 400 kg make it an ideal solution for demanding production applications.

The Surface Grinding Machine 300x1000 was designed for maximum precision and efficiency in metalworking, offering advanced technological solutions that set it apart in the segment of surface grinders. Its construction and technical parameters provide measurable benefits in production environments where repeatability, durability and high-quality finishing are essential. Below are the key machine advantages that make it an indispensable tool in professional workshops and factories:

The Surface Grinding Machine 300x1000 features a robust construction combining durability with advanced technology. The machine bed, made of high-quality cast iron, ensures rigidity and minimises vibrations during machining, which is essential for precision grinding. The spindle running at 1450 rpm, mounted in precision bearings, works with a 350 x 40 x 127 mm grinding wheel, ensuring stable and uniform machining. The hydraulic system supports longitudinal table feeds in the range of 7–23 m/min, while automatic cross and vertical feeds allow precise movement control with an accuracy of 0.005 mm. The magnetic table measuring 300x1000 mm ensures secure clamping of workpieces, speeding up preparation for machining. The integrated cooling system effectively dissipates heat, preventing thermal deformation and extending tool life. The drive motors, including the 5.5 kW spindle motor, are optimised for energy efficiency and low noise levels. The total mass of 3500 kg emphasises the stability and reliability of the machine in heavy industrial environments.

The Surface Grinding Machine 300x1000 offers exceptional precision thanks to advanced feed and control mechanisms. The automatic cross feed in the range of 0.1–8 mm and vertical feed from 0.005 mm allow tolerances below 0.01 mm, which is crucial when producing precision components. The maximum table feed of 350x1100 mm with cross speeds up to 990 mm/min allows fast machining of large surfaces without compromising accuracy. The grinding wheel operating at 1450 rpm ensures even material removal, minimising tool wear and improving surface finish quality. The digital readout system for all three axes eliminates manual errors, reducing setup time and increasing throughput in production cycles. Compared to other surface grinders, this model stands out with a high load capacity of 400 kg, allowing heavier workpieces to be machined with no loss of precision. Energy efficiency of the motors and solid construction minimise downtime, making this magnetic surface grinder an effective tool in optimising production processes.

The Surface Grinding Machine 300x1000 is designed for manufacturing plants specialising in metalworking, such as tool shops, machine component factories and service centres. It excels in grinding flat surfaces of components such as dies, injection moulds, base plates and precision parts requiring high dimensional accuracy. In B2B environments where repeatability and efficiency are priorities, this magnetic surface grinder supports both batch and single-piece production, machining materials such as steel, cast iron and aluminium alloys. Its applications also include refurbishment of worn components in heavy industry, where the maximum distance from table to spindle of 580 mm allows larger workpieces to be machined. The machine is particularly recommended for companies seeking to automate grinding processes, thanks to automatic feeds and digital readout, which reduce dependence on operator skill.

| Worktable size | 305 x 1020 mm |

| Maximum table feed | 350x1100 mm |

| Maximum table load | 400 kg |

| Grinding wheel dimensions | 350 x 40 x 127 mm |

| Grinding wheel speed | 1450 rpm |

| Maximum distance spindle axis – table | 580 mm |

| Table travel speed | 7 - 23 m/min |

| Automatic cross feed | 0.1 - 8 mm |

| Rapid cross feed | 990 mm/min |

| Magnetic table size | 300 x 1000 mm |

| Y-axis graduation | 0.02 mm |

| Z-axis graduation | 0.005 mm |

| Rapid vertical feed | 610 mm/min |

| Automatic vertical feed | 0.005 - 0.05 mm |

| Spindle motor power | 5.5 kW |

| Total motor power | 9 kW |

| Machine area incl. table travel | 4400 x 2200 x 2050 mm |

| Weight | 3500 kg |

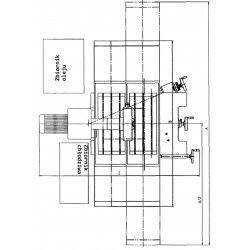

Limit position diagram

| A | B | C |

| 4400 mm | 2085 mm | 2200 mm |

Contact us to obtain a detailed offer for the 300x1000 surface grinding machine. Our specialists will help you select the optimal configuration tailored to your production facility’s requirements.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Solidna i trwała maszyna, idealna do precyzyjnych zastosowań.

Bardzo dokładna obróbka, nie wymaga częstych regulacji.

Obsługa prosta i intuicyjna, maszyna bardzo stabilna.

Bardzo wydajna, świetna zarówno do jednostkowej, jak i seryjnej produkcji.

Maszyna działa płynnie, bezawaryjna i wydajna.

Mocna konstrukcja, nie ma żadnych luzów, doskonała dokładność.

Świetna jakość obróbki, trzyma wymiar nawet przy długiej pracy.

Bardzo dobrze wykonana maszyna, stabilna i niezawodna.

Szlifierka bardzo dokładna, świetnie sprawdza się przy wymagających pracach.

Surface Grinding Machine CORMAK 400x1000 (406x1020)

Our surface grinder is an excellent solution for production requiring continuous grinding. Designed according to the latest industrial standards, this machine offers a wide grinding range using a programmable SIEMENS PLC controller. The stable construction ensures reliability and a modern ...More

Surface Grinding Machine CORMAK 600x1500

Our industrial surface grinder is the key to achieving outstanding production performance, reliability in toolrooms and efficiency in maintenance departments. Its impressive size is matched by a modern and robust construction, making it the ideal tool for precision grinding in the most demanding ...More

Surface Grinding Machine CORMAK 400x800 (406x813)

Our modern continuous-operation surface grinder is the key to efficient production. Equipped with a programmable SIEMENS PLC controller, it enables high-level machine operation. The stable design ensures precise grinding while meeting the latest safety standards. Two pairs of spindle head guides ...More

Surface Grinding Machine CORMAK 610x1600

Our industrial surface grinder is the key to achieving outstanding performance in production, reliability in toolrooms, and efficiency in maintenance departments. Its impressive size is matched by a modern and solid design, making it the ideal tool for precision grinding even in the toughest ...More

Surface Grinding Machine CORMAK 200x500

Surface grinder for continuous production work, large grinding range and SIEMENS PLC programmable controller. Features a modern, stable design. The spindle head operates on two pairs of guides. Automatic feeds for 3 axes, digital readout included as standard. ...More

Surface Grinding Machine CORMAK 300x600

Our NC surface grinder is a perfect solution for continuous production, offering a wide grinding range supported by an advanced SIEMENS PLC controller. Its stable construction guarantees precise and repeatable results. Two pairs of spindle head guides ensure the required stability, while automatic ...More

Surface Grinding Machine CORMAK 400x1000 (406x1020)

Our surface grinder is an excellent solution for continuous production, offering a wide grinding range with a programmable SIEMENS PLC controller. Its stable construction ensures precision and repeatability. Two pairs of spindle head guides provide the required rigidity, while automatic feeds for ...More

Surface Grinding Machine CORMAK 810x4000

Our industrial surface grinder is the key to efficient production, reliable performance in toolrooms, and effective maintenance operations. Its impressive size and modern, stable design allow for precision grinding even under the most demanding conditions. Dual spindle head guideways ensure smooth ...More

Surface Grinding Machine CORMAK 300x600

Surface grinder for continuous production work, a large grinding range and SIEMENS PLC programmable controller. Features a modern, stable structure. The spindle head operates on two pairs of guides. Automatic feeds for 3 axes, digital readout included as standard. ...More

2024-08-18

Doskonały wybór

Świetna szlifierka, spełnia wszystkie oczekiwania, polecam!