What Functions Does a Machining Centre Offer?

A CNC machining centre is a machine designed for advanced material processing, using automated tools to perform multiple operations on a single workpiece. The main functions include:

– Milling – using precision cutters, CNC machining centres allow processing along three axes, enabling the creation of complex shapes.

– Drilling – accurate holes of various diameters can be produced regardless of material hardness, thanks to high-performance drilling tools.

– Thread Cutting – CNC machining centres enable precise thread formation, essential for manufacturing assembly components.

– Boring – allows enlarging holes while maintaining perfect geometry, crucial in applications requiring high dimensional accuracy.

In addition, CNC machining centres feature automation that shortens production time and minimises human error. The CNC control system provides full process supervision, ensuring excellent quality of the finished components.

Types of Machining Centres Offered by CORMAK

CORMAK provides a wide selection of machining centres to meet diverse industrial requirements.

Vertical Machining Centres

Vertical machining centres are ideal for machining parts with complex geometries. With a vertically mounted spindle, they allow precise operations on multiple planes. CORMAK models are known for high rigidity and positioning precision.

Horizontal Machining Centres

Horizontal machining centres differ by spindle orientation, which is mounted horizontally to enable machining of parts on horizontal surfaces. They are ideal for processing larger or heavier components requiring a stable position during machining.

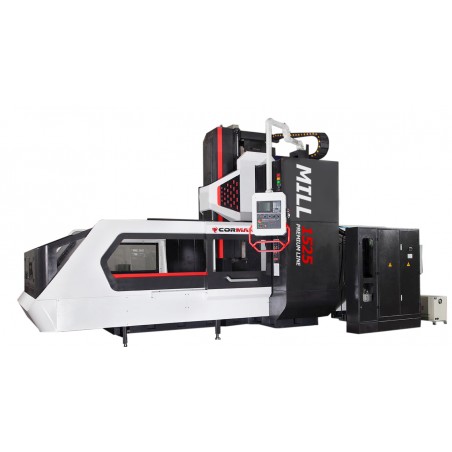

Gantry Machining Centres

Gantry machining centres are characterised by robust construction and the ability to machine large-scale components of non-standard dimensions. The gantry structure allows precise milling, drilling and threading of oversized parts — particularly suited to heavy industry applications.

Why Invest in a CNC Machining Centre?

Investing in a CNC machining centre is a strategic move towards higher productivity. These industrial machines offer:

– Precision – machining centres deliver accuracy beyond traditional manual processing methods.

– Repeatability – automation eliminates the risk of operator error, crucial for batch production.

– Time Efficiency – advanced functions such as automatic tool changing significantly shorten cycle times.

– Safety – enclosed work chambers ensure operator protection and reduce noise levels.

– Versatility – a single machine can perform multiple operations, ideal for complex component manufacturing.

Thanks to advanced control systems and modern design, CORMAK CNC machining centres are reliable tools that can greatly enhance your company’s competitiveness. As a manufacturer of industrial machinery, CORMAK also offers other CNC machines to help you fully equip your production facility.