The basket is empty.

Horizontal machining centres equipped with a horizontally mounted spindle provide the capability for precise and fast machining of various components, both in automated series production and continuous manufacturing of metal parts and machine elements. Machines from the PREMIUM LINE series are designed for the most demanding users. The high quality of components ensures reliability and long service life, offering greater precision and productivity when using multiple tools. Each machining centre is built with premium components from leading Taiwanese, German, Japanese and Chinese manufacturers, including HIWIN, POSA, SIEMENS, FANUC, OMRON, PRAGATI, SCHNEIDER, CHANDOX, FAG and BOSCH REXROTH.

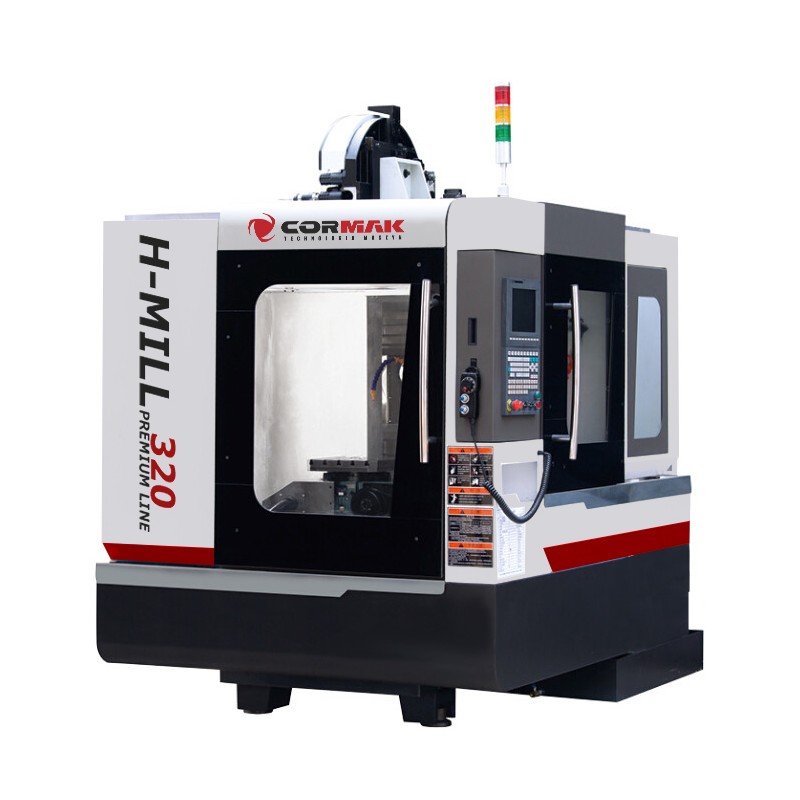

The H-MILL 320 Horizontal Machining Centre is an advanced CNC machine designed for precision metalworking in compact production environments. Equipped with modern controls and a rigid structure, this metalworking machining centre offers high performance and reliability for demanding industrial applications.

The H-MILL 320 Horizontal Machining Centre combines compact size with advanced technological capability, offering significant benefits in production processes. Key features include:

The H-MILL 320 CNC machining centre is the perfect choice for companies looking for a compact yet powerful metalworking solution that combines advanced technology with operational simplicity.

The H-MILL 320 machining centre is designed for maximum precision and durability within a compact footprint. Key structural components include:

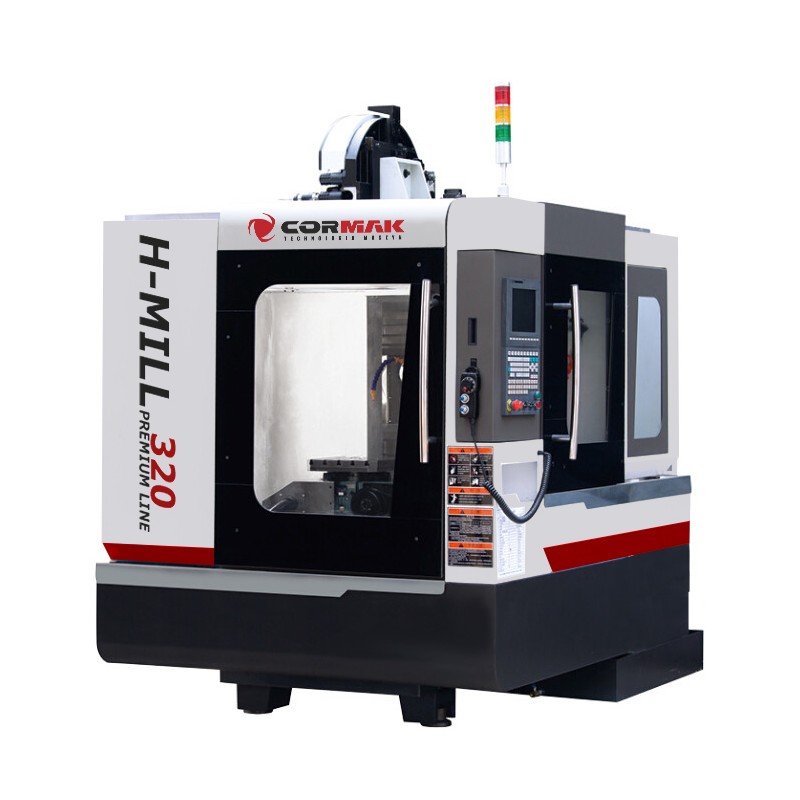

The solid cast-iron base provides excellent rigidity and vibration damping during machining. The 320x320 mm table with a maximum load capacity of 250 kg allows efficient machining of small and medium-sized components.

The BT30 spindle with a power of 15/18.5 kW and a speed of 10,000 rpm ensures high cutting efficiency, particularly when machining materials such as aluminium or stainless steel. The automatic lubrication and cooling systems protect the spindle from overheating and wear.

Linear guides and Siemens servo drives ensure smooth motion along the X, Y and Z axes (500x450x400 mm travel), minimising positioning errors and providing high dynamic performance.

The 24-tool magazine enables quick tool changes, improving production efficiency and allowing machining of multiple parts in one setup.

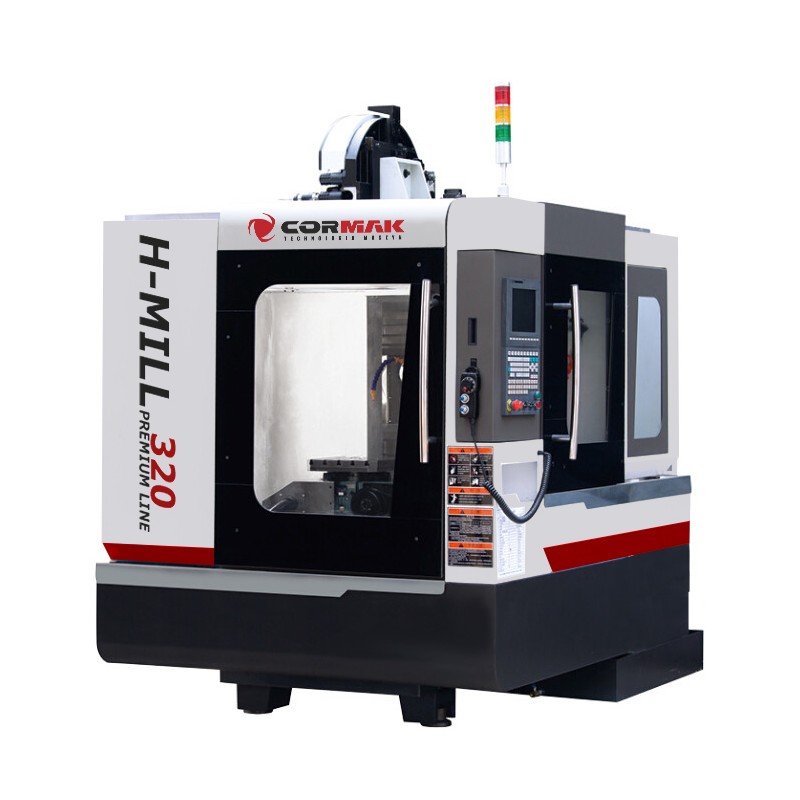

The H-MILL 320 CNC centre offers outstanding precision with positioning accuracy of ±0.005 mm and repeatability of ±0.003 mm. High rapid feed speeds of 60 m/min and advanced CNC control systems (Siemens or Fanuc) optimise toolpaths, reducing machining time and material waste. Its compact design and high dynamics make it ideal for both batch and single-part production in smaller facilities.

The H-MILL 320 Metalworking Machining Centre is used across multiple industries, including:

Thanks to its compact design and versatility, this CNC machining centre is an ideal solution for facilities with limited space that require precise and flexible production capabilities.

The H-MILL 320 Horizontal Machining Centre offers advanced CNC control systems from Siemens and Fanuc, ensuring precision, performance and user-friendly operation in a variety of industrial applications.

Siemens Sinumerik 808D is an economical CNC control system for metal milling machines, offering:

Sinumerik 828D is a professional CNC control system for metal machining centres, offering:

Fanuc Oi-TF is a reliable CNC control system for industrial machining centres, featuring:

Choose the CNC control system that best suits your production requirements to maximise machining efficiency and precision!

| Table travel (X/Y/Z) | 500x450x400 mm |

| Table dimensions | 320x320 mm |

| Maximum table load | 250 kg |

| Rapid feed (X/Y/Z) | 60/60/60 m/min |

| Spindle speed | 10,000 rpm |

| Spindle taper | BT30 |

| Tool magazine capacity | 24 |

| Positioning accuracy (X/Y/Z) | ±0.005 mm (JIS) |

| Repeatability | ±0.003 mm (JIS) |

| Motor power | 15/18.5 kW |

| Machine weight | 2700 kg |

| Machine dimensions | 2500x1900x2500 mm |

*The price quoted is for the machine only, excluding optional/additional equipment, installation, transport and training — please contact our consultant for more details.

As an experienced CNC machine manufacturer, CORMAK has been delivering reliable industrial solutions for over 20 years. Our CNC machining centres meet the highest European safety standards and are supported by professional service. With extensive warehouse facilities (over 15,000 m²) and a team of experts, we provide comprehensive technical support and consultation.

By choosing CORMAK machining centres, you invest in precision, reliability and long-term production efficiency.

Boost your production accuracy and performance with the H-MILL 320 Horizontal Machining Centre. Contact our team for detailed information, a tailored quotation or a live demonstration. Contact us!

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

CNC Horizontal Machining Centre CORMAK H-MILL 800

Machining centres equipped with a horizontal spindle axis enable precise and fast machining of various components, both in automated serial production and continuous manufacturing of metal parts and machine elements. The machines from the PREMIUM LINE series are designed for the most demanding ...More

CNC Horizontal Machining Centre CORMAK H-MILL 500

H-MILL 500 Horizontal Machining Centre – Precision and efficiency in CNC machining The H-MILL 500 Horizontal Machining Centre is an advanced CNC machine designed for high-precision metalworking in industrial environments. Featuring a compact construction, modern CNC controls and ...More

Horizontal Machining Centre CORMAK H-MILL 630

Machining centres equipped with a horizontal spindle axis ensure precise and fast machining of various components, both in automated serial production and continuous manufacturing of metal parts and machine elements. The machines from the PREMIUM LINE series are designed for the most demanding ...More

Write your review

* Required fields

I accept privacy policy rules