The basket is empty.

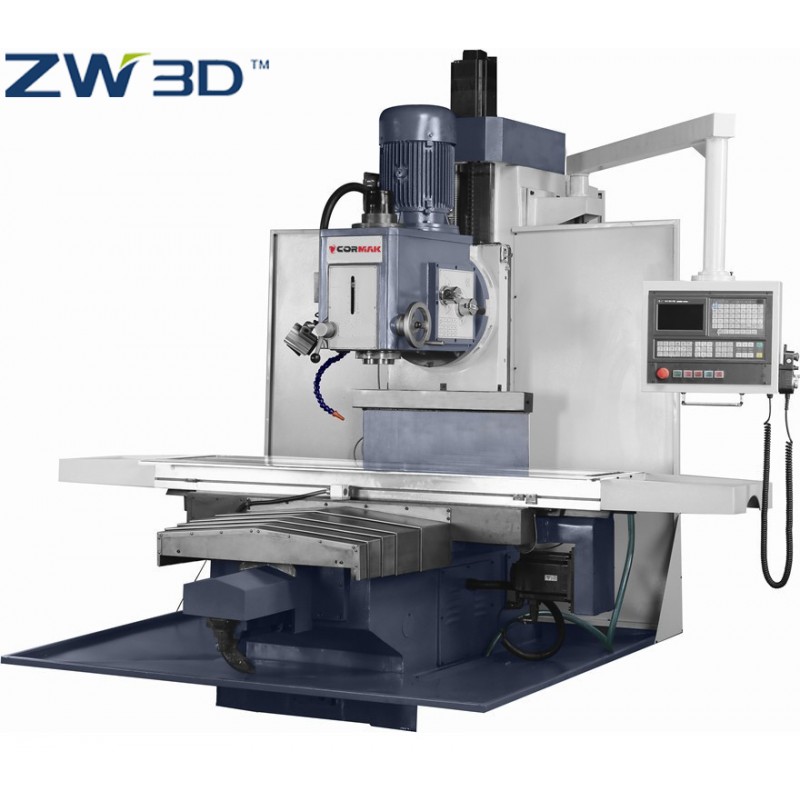

Heavy, solid construction and a wide movement range in all 3 axes provides high flexibility in machining various workpieces.

Remarkably fast and simple programming provides quick reconfiguration possibilities.

SINUMERIK 808D control is the newest control system put on the market by Siemens company, designed for standard turning lathes and milling machines. Its constructors, having 50-years of experience as a company creating CNC systems and newest solutions in the systems architecture, components and software, equipped them with functionalities and technological capabilities which were until now available only in control systems of higher grade machines. SINUMERIK 808D is a single, compact panel, which reduces the number of necessary connections and interfaces to a minimum. All of the components of the system were made with strict requirements and quality standards, achieving a high protection rating (IP65 at the front side of the panel) and providing a possibility to use the machine even in an unfriendly environment. 808D control system is characterized by a high comfort and simple operation. It is equipped with a keyboard configured specifically for technological operations, with mechanical buttons (ensuring maximum comfort during data entering), functional membrane buttons and with programmable buttons.

|

Table dimensions |

2000×400 mm |

|

Shank mount |

ISO 50 |

|

Travel range |

1500×550 mm |

|

Table load capacity |

2000 kg |

|

Spindle taper distance from table surface |

150–700 mm |

|

Spindle axis distance from vertical guide |

600 mm |

|

Quick feed speed |

30/30/24 m/min |

|

Feed speed |

2.5–25000 mm/min |

|

Spindle speed |

66–1440 rpm |

|

Spindle motor power (AC servo) |

7.5 kW |

|

Number of tools |

1 |

|

Maximum tool dimensions |

130×300 mm |

|

Maximum tool weight |

8 kg |

|

Positioning accuracy |

± 0.04 mm |

|

Positioning repeatability accuracy |

± 0.02 mm |

|

Minimum tool change time |

-------- |

|

Dimensions |

3000×2500×2560 mm |

|

Weight |

4650 kg |

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

VM1320 milling machines are intended for small scale and individual elements machining. Due to a heavy cast-iron bed and a large table, the machine offers high flexibility with regard to various production needs, even during small scale and individual elements machining. Remarkably fast and simple ...More

Universal industrial milling machine with CNC control intended for heavy industry operations and crafting, irreplaceable for tool rooms and repair departments. The machine is equipped with a horizontal spindle and a vertical swivel head. A table of 1370×360 allows for machining big and heavy workpieces. ...More

Universal industrial milling machine with CNC control intended for heavy industry operations and crafting, irreplaceable for tool rooms and repair departments. The machine is equipped with a horizontal spindle and a vertical swivel head. A table of 1600×360 allows for machining big and heavy workpieces. ...More

VM1700 milling machines are intended for small scale and individual elements machining. Due to a heavy cast-iron bed and a large table, the machine offers high flexibility with regard to various production needs, even during small scale and individual elements machining. Remarkably fast and simple ...More

Write your review

* Required fields

I accept privacy policy rules