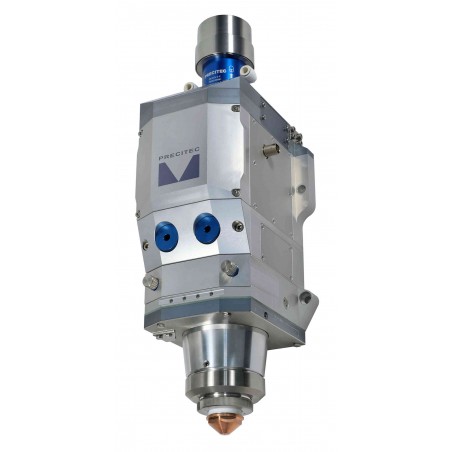

The Precitec head is a key element of the cutting system: it maintains the correct distance from the material, shapes the assist-gas stream and protects the optics from contamination. The modern capacitive sensor and autofocus system stabilise piercing and kerf guidance, keeping edges smooth and part geometry consistent from the first to the last piece. The optimised nozzle chamber and high-quality protective lenses minimise buildup and spatter, extending lens life, reducing parameter adjustments and maintaining constant quality across different materials and thicknesses.

A major advantage of Precitec heads is their service-friendly design: easy access to protective glass, clear nozzle and seal mounting, and intuitive adjustment points shorten setup and maintenance times. Combined with stable cooling and efficient fume extraction, the head maintains constant thermal and optical conditions, reducing power drift and ensuring clean, repeatable edges. When selecting a model, consider the laser source power, material types (carbon steel with oxygen, stainless steel and aluminium with nitrogen or air) and preferred nozzle diameters — proper matching allows full use of the machine’s dynamics without compromising quality.