CORMAK LUFT 1500 INVERTER Screw Compressor – power and precision for your business

Looking for a professional solution to power pneumatic tools in a workshop, paint shop or production line? The CORMAK LUFT 1500 INVERTER screw compressor is the perfect choice. With a power of 11kW and an impressive real output of up to 1580L/min, it provides a constant supply of compressed air essential for efficient operation of impact wrenches, blow guns or spray guns. This model is designed for continuous operation, making it ideal for demanding applications such as tyre services, large automotive workshops and production plants. Investing in a CORMAK screw compressor means a significant improvement in working comfort – say goodbye to noisy piston compressors and enjoy quieter and more stable operation.

LUFT 1500 INVERTER features a direct drive system, resulting in significantly better efficiency and reduced power loss compared to belt-driven models. This innovative design guarantees optimal utilisation of motor power and, consequently, higher performance with lower energy consumption. The maximum pressure generated by this screw compressor is 10bar. Full control over operating parameters is ensured by the intuitive MAM electronic control panel, giving access to key compressor information and enhancing flexibility and control over processes.

✅ Pressure: up to 10 bar | ✅ Capacity: up to 1580 L/min | ✅ Power: 11 kW

CORMAK Screw Compressors: When you expect the highest quality and performance!

Looking for solutions that exceed market standards? CORMAK screw compressors are synonymous with innovation and reliability, designed for the most demanding applications.

- Innovative design: Our compressors are based on advanced engineering and European manufacturing precision. The robust construction, enhanced with modern components, guarantees long-lasting and trouble-free operation in all conditions.

- Quiet operation and comfort: Designed with attention to detail, our compressors are exceptionally low-noise. Efficient sound and vibration reduction systems provide a comfortable working environment, improving concentration and operator well-being.

- Intelligent control: The intuitive MAM electronic control panel is the command centre of your compressor. It allows precise monitoring of parameters, scheduling maintenance and quick diagnostics, ensuring stability and protection of key components.

- Adaptable to your needs: Each application is unique. CORMAK compressors can be configured with additional air treatment systems, perfectly tailored to the specific needs of your industry.

- Dynamic working pressure: Automatic pressure regulation ensures the compressor supplies exactly as much compressed air as needed, maximising energy efficiency and minimising losses.

- Sustainable development: CORMAK focuses on environmentally friendly solutions. Energy-saving technologies reduce your bills and environmental impact, while heat recovery options maximise energy use.

CORMAK: Technology that drives your success!

Main advantages of the 11kW induction motor with inverter

- Significant energy savings: The inverter enables smooth and precise speed control of the induction motor. The compressor adjusts its output to the current air demand, avoiding idle running, start/stop cycles and energy loss from venting excess air. Depending on the air consumption profile, savings can reach from 25% to even 50%.

- Stable system pressure: Continuous speed control maintains nearly constant air pressure regardless of demand fluctuations, ensuring pneumatic tools and machines work correctly and processes remain precise.

- Reduced start-up current and network load: The inverter-driven motor starts smoothly, eliminating high start-up currents that could burden the electrical network and cause voltage drops, thus protecting infrastructure and reducing disturbances.

- Extended component life: Smooth operation without sudden starts and stops reduces mechanical stress on the screw block, bearings, couplings and the motor itself, resulting in longer compressor life and lower maintenance costs.

- Quieter operation: At lower speed, the compressor produces less noise, improving acoustic comfort for operators and the surroundings.

- Greater flexibility: The inverter-equipped compressor efficiently handles varying air demand throughout the day or production cycle.

- Advanced control and diagnostics: Integrated inverter control enables advanced monitoring, fault diagnostics, remote management and maintenance scheduling.

The combination of proven induction motor reliability and intelligent inverter control makes the screw compressor an extremely efficient, economical and flexible source of compressed air, perfectly suited to the dynamic needs of modern industry.

Screw module – the heart of your compressor

High-quality CORMAK screw compressors, such as the LUFT 1500 inverter model, are based on advanced screw modules that determine their performance and reliability. Each module is engineered with precision to withstand intensive industrial operation.

Key features of CORMAK screw modules:

- Modern technology and efficiency: The screw modules ensure excellent performance and exceptional energy efficiency, focusing on maximum output with minimal energy use.

- Precision and control: Advanced technical design allows precise control of compressed air generation, ensuring stable pressure and optimal system operation.

- Durability and reliability: Designed for longevity and industrial durability, ensuring minimal downtime and maintenance.

By choosing a CORMAK compressor, you invest in technology built on years of experience and continuous innovation, delivering improved efficiency and productivity for your business.

Integrated inverter – foundation of efficiency and savings

In CORMAK screw compressors like the LUFT 1500, the built-in inverter is the key component that revolutionises compressed air supply, ensuring intelligent motor control and significant user benefits.

How it works and what you gain:

The inverter allows smooth speed control of the motor, providing precise regulation of compressor output. In practice, it supplies exactly the air required at any given moment, unlike traditional full-load/idle compressors.

Main advantages of the integrated inverter:

- Smooth start and quiet operation: Eliminates high current surges during start-up, ensures quiet and stable work from the start.

- Maximum energy savings: The variable-speed drive adjusts energy use to current air demand, saving up to 50% electricity.

- Extended component life: Smooth operation without abrupt starts/stops reduces wear and extends service life, lowering maintenance costs.

The integrated inverter in CORMAK compressors is an investment that quickly pays off, ensuring savings, precision, and reliability in air supply.

Intuitive CORMAK control panel – full control at your fingertips

The advanced MAM control panel ensures reliable and optimised operation of your air system, enabling ongoing monitoring and instant response to all key parameters.

Features of the CORMAK control panel:

- Comprehensive monitoring: Real-time tracking of all vital parameters such as pressure, temperature and operating status.

- Easy adjustment: Intuitive interface allows quick parameter configuration to match system requirements.

- Instant notifications: Automatic alerts in case of faults or maintenance needs for maximum uptime.

The CORMAK control panel ensures reliability and performance, offering precise control of your compressed air system.

Technical specifications

|

|---|

| Motor power |

11kW |

| Voltage |

400V/50Hz |

| Output 0–6 bar |

1620L/min |

| Output at 6 bar |

1580L/min |

| Output at 8 bar |

1350L/min |

| Output at 10 bar |

1230L/min |

| Outlet connection (G) |

1" |

| Dimensions |

1170×730×1020mm |

| Weight |

243kg |

Refrigeration Air Dryer IZBERG N20S

Compressed air dryer CORMAK is a professional industrial device designed to effectively remove moisture, water vapour and oil particles from pneumatic systems. Using efficient refrigeration technology, the dryer ensures stable operation of air-powered equipment, increasing its durability and reliability. It is an ideal solution for companies seeking modern air treatment in pneumatic installations.

Main advantages of the CORMAK compressed air dryer

- Advanced refrigeration system — a two-stage air-cooling process down to the dew point ensures efficient separation of moisture and oil particles.

- Stable operation in systems up to 10 bar — suitable for standard industrial installations.

- High efficiency — up to 2800 L/min, making it an efficient solution for medium and larger compressed-air systems.

- Energy-saving design — a variable-speed fan reduces power consumption to only 0.58 kW.

- Automatic condensate drain valve — ensures reliable condensate discharge without operator supervision.

- Compact dimensions and easy installation — perfect for upgrading existing pneumatic systems.

- Eco-friendly refrigerant R134a — guarantees high performance while meeting environmental standards.

Design and technology

The refrigeration dryer is engineered for maximum efficiency and durability. Its main structural components include:

1. Air-to-air heat exchanger

In the first stage, incoming air passes through a heat exchanger where it is pre-cooled by the colder outgoing air leaving the evaporator. The counter-flow process increases overall energy efficiency.

2. Refrigeration circuit evaporator

In the second stage, compressed air enters the evaporator, where it is cooled to a dew-point temperature of 3 °C. This causes water vapour and oil particles to condense.

3. Condensate separator

After cooling, the gas-condensate mixture flows into a high-efficiency separator, where condensate is removed automatically.

4. Fan-speed control system

The variable-speed fan technology automatically adjusts cooling intensity to the real demand, reducing energy use and extending component life.

Precision and performance

Thanks to refrigeration technology, the CORMAK dryer efficiently removes water and oil, protecting installations against corrosion, actuator seizure and tool damage. The constant dew-point temperature ensures consistent air quality and reliable pneumatic-system performance.

Applications

The CORMAK air dryer is used across many industrial sectors where air purity and dryness are crucial for machine reliability. Typical applications include:

- Mechanical workshops

- Production plants

- Food industry (with appropriate filtration)

- Electronics industry

- Industrial automation

- Paint-spraying systems and booths

- Pneumatic-drive CNC equipment

Equipment

- Automatic condensate drain valve

- Built-in water-oil separator

- Variable-speed fan — automatic adaptation to working conditions

- Electronic control system — stable operating parameters

- Compact, durable housing resistant to industrial environments

Technical specifications

| Parameter | Value |

|---|

| Inlet/outlet pipe diameter (BSP) |

1" |

| Maximum working pressure |

10 bar |

| Maximum inlet-air temperature |

≤ 38 °C |

| Dew-point temperature |

3 °C |

| Capacity |

2800 L/min |

| Power |

0.58 kW |

| Supply voltage |

230 V |

| Dimensions (L × W × H) |

420 × 700 × 690 mm |

| Weight |

37 kg |

| Refrigerant type and amount |

R134a, 550 g |

Choose professional air treatment

By selecting a CORMAK refrigeration air dryer, you invest in the stability and efficiency of your pneumatic system. It is an essential part of any professional compressed-air setup — particularly where high air purity and machine protection are required.

Do not risk losses caused by moisture in your pneumatic system — choose the CORMAK air dryer and gain full control over air quality!

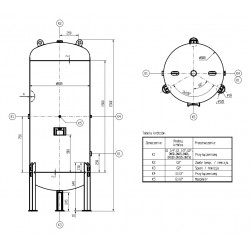

1000 L AIR RECEIVER WITH FITTINGS – HIGH-QUALITY PRESSURE TANK FOR COMPRESSED-AIR SYSTEMS

The CORMAK pressure tank with a capacity of 1000 L and a working pressure of 11 bar is a reliable solution for storing compressed air in industrial plants, workshops and pneumatic installations. The robust steel construction and compliance with EU directives make it an indispensable element of every compressed-air system. Its optimised design and high pressure resistance allow it to function both as a storage buffer and as a stabilising element of compressor operation.

Main advantages of the 1000 L CORMAK pressure vessel

- Professional pressure-vessel design – made of high-grade 4 mm steel, resistant to pressure and corrosion.

- CE certification – complies with European safety and quality standards.

- Working pressure 11 bar – suitable for most pneumatic systems, including those with higher requirements.

- High capacity – 1000 L – ensures stable air supply and reduces compressor start frequency.

- Multi-connection system – six connections (2", 1/2") allow flexible installation.

- Excellent build quality – anti-corrosive coating inside and outside.

- Vertical design – saves valuable floor space.

Design and technology – solid construction for demanding applications

This compressed-air receiver is designed for intensive industrial use. The body made of structural steel with 4 mm wall thickness withstands up to 11 bar and ensures long-term durability. All welds are strictly quality-controlled, and the surfaces are protected with anti-corrosion coating resistant to chemical and environmental factors.

The tank is marked with a CE nameplate and identification number confirming conformity with European requirements. It comes with full technical documentation and material certificates.

Precision and efficiency – stable pressure and optimal compressor performance

Thanks to its 1000-litre capacity, the receiver acts as an air buffer stabilising system pressure throughout the pneumatic network. This enables smooth operation of air-powered devices and extends compressor life by reducing start/stop cycles. The vertical layout allows compact installation, ideal for limited-space facilities.

A properly selected air-compressor tank minimises pressure drops and prevents system overload, improving performance and safety.

Applications – versatile for industrial and workshop use

CORMAK air receivers are widely used in many industries, including automotive, production, construction and central pneumatic systems. They perform perfectly as:

- Compressor tank – air storage for pneumatic supply systems,

- Compressor buffer vessel – pressure stabiliser reducing compressor operating frequency,

- Compressed-air receiver – continuous supply for pneumatic machines and devices,

- Component in automation and painting systems,

- Key element of pneumatic-control installations.

Standard equipment

- Connection ports: 6 pcs – 2", 1/2"

- CE identification plate

- Full technical documentation and pressure certificate

- Internal and external anti-corrosive coating

Technical specifications:

| Weight (kg) |

230 |

| Connections |

6 |

| Connection size |

2", 1/2" |

| Size |

230 × 80.8 cm |

| Tank capacity (L) |

1000 |

| Working pressure (bar) |

11 |

| Wall thickness (mm) |

4 |

| Diameter (mm) |

Ø 808 |

| Height (mm) |

2300 |

Accessories for the tank

- ½-inch plug – 2 pcs

- ½-inch nipple – 1 pc

- ½-inch tee – 1 pc

- ½ to ¼-inch reducer – 1 pc

- ¼-inch pressure gauge – 1 pc

- 1 to ¾-inch reducer – 2 pcs

- ½-inch ball valve – 1 pc

Note !!!

The safety valve is not included and must be purchased separately.

Contact us to order a unit tailored to your installation!