- Reduced price

The basket is empty.

Accurate and efficient industrial bender for steel, copper, aluminium, and brass tubes. The ability to select the optimal bending radius ensures high-quality results without material deformation. This tube bender is easy to operate and ideal for low and medium-volume production in the automotive, furniture, architectural, and tooling industries. The main bending die is driven by a geared electric motor. The machine operates in both manual and semi-automatic modes. Its simple, robust design guarantees long-lasting, trouble-free operation and ease of use.

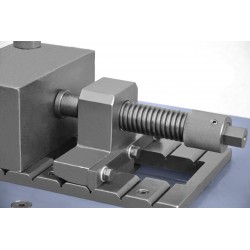

The Tube and Profile Bender BENDMASTER 70 is an industrial mandrel-free machine designed for precise bending of steel tubes, square profiles, and large cross-section materials. With its solid construction, automated bending angle measurement system, and powerful drive, the machine guarantees repeatability, efficiency, and reliability – even under heavy-duty production conditions. It is ideal for applications in heavy industry, construction, and industrial installations.

BENDMASTER 70 is designed as a mandrel-free roll-type bender with an electro-hydraulic drive, adapted for heavy-duty operation. The 5 kW main motor ensures stable and safe bending of large-diameter tubes. The digital bending angle measurement system, integrated with the control panel, allows accurate programming and monitoring of working parameters. Its compact design enables integration with production lines and ensures long-term reliability.

The BENDMASTER 70 steel tube bender offers full control over the bending process. The 1.2 rpm bending speed guarantees accuracy and process safety, while the 2.4 rpm return speed increases efficiency. Bending up to 180° allows forming of full arcs and spirals, even in large structural tubes. The machine is designed for precise forming of components where tolerance and repeatability are critical.

The BENDMASTER 70 bender is used across multiple industries, including:

| Maximum tube diameter | 70 × 5 mm |

| Maximum square profile dimension | 50 × 50 × 2 mm |

| Maximum bending angle | 180° |

| Bending die speed | 1.2 rpm |

| Return speed | 2.4 rpm |

| Main motor power | 5 kW |

| Machine dimensions | 1300 × 700 × 900 mm |

| Weight | 680 kg |

Boost your production capabilities with the industrial mandrel-free bender BENDMASTER 70 – precision, power, and durability combined in one machine. Contact our technical department for a tailored offer and configuration suited to your production requirements.

Manufacturer: Cormak

CORMAK JERZY ZALEWSKI

Brzeska 120, 08-110 Siedlce, Poland

phone: +48 501 944 934

export@cormak.pl

phone: +48 609 939 400

export@cormak.pl

phone: +48 609 939 051

export@cormak.pl

phone: +48 609 939 741

export@cormak.pl

Laser Welding Machine CORMAK WL2000 3in1 – Special Offer

We present the latest industrial laser welding machine CORMAK WL2000, which combines advanced FIBER technology with innovative design solutions, offering unmatched precision and performance. Designed for welding various types of metals, it ensures top-quality and repeatable welds. Thanks to its ...More

Mandrel-Free Tube and Profile Bending Mashine CORMAK BENDMASTER 50

Accurate and efficient industrial bender for steel, copper, aluminium, and brass tubes. The ability to select the optimal bending radius ensures high-quality results without material deformation. This pipe bender is easy to operate and ideal for small-batch and custom production in the automotive ...More

Mandrel-Free Tube and Profile Bending Mashine CORMAK BENDMASTER 80

Accurate and efficient industrial bender for steel, copper, aluminium, and brass tubes. The ability to select the optimal bending radius ensures high-quality results without material deformation. This pipe bender is easy to use and ideal for small- and medium-batch production in the automotive, ...More

Mandrel-Free Tube and Profile Bending Mashine CORMAK BENDMASTER 40A

Electric mandrel-free tube bender. A precise and efficient machine for bending steel, copper, aluminium, and brass tubes. The ability to select the optimal bending radius ensures high-quality results without material deformation. This pipe bender is easy to operate and ideal for small-batch and ...More

Write your review

* Required fields

I accept privacy policy rules